Abstract

Piezoelectric generators (PEGs) have applications in future wearable and implantable technologies, but suffer from insufficient flexibility, poor biocompatibility, facile biodegradation, and low energy output. In this work, a design concept for a piezoelectric elastomer is proposed. Uniquely, we focus on develo** a complete “green” design concept, considering the selection of a bio-based monomer, polymer fabrication, and biodegradation. The piezoelectric elastomer, which was prepared by the copolymerization of lactate, 1,4-butanediol, and sebacate monomers, is capable of generating an output voltage of 303.75 mV cm−2 and an output current of 1.92 × 10–2 mA cm−2, which are 7.11 times and 4.01 times, respectively, higher than those of a conventional polyvinylidene fluoride–trifluoroethylene copolymer (PVDF-TrFE)-based PEG under the same measurement conditions. Such efficient piezoelectric conversion is attributed to the reduced elastic modulus of the elastomer, which resulted from the random polymerization between piezoelectric lactate monomers and linear 1,4-butanediol and sebacate monomers. As a result, the elastomer generates a greater piezoelectric charge on deformation than traditional PVDF-TrFE. Further, the relative growth rate of L929 mouse fibroblast cells grown on the modified elastomer was unaffected, demonstrating the good biocompatibility of the piezoelectric elastomer. On the basis of the overall environmentally friendly product cycle and high piezoelectric output, this PEG shows promise for applications in future wearable and implantable technologies.

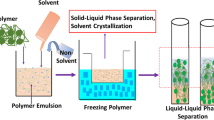

Graphical abstract

Similar content being viewed by others

References

Sezer N, Koç M, A, (2021) comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy 80:105567. https://doi.org/10.1016/j.nanoen.2020.105567

**e XD, Wang Q (2015) Energy harvesting from a vehicle suspension system. Energy 86:385–392. https://doi.org/10.1016/J.ENERGY.2015.04.009

Shi Q, He T, Lee C (2019) More than energy harvesting–Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy 57:851–871. https://doi.org/10.1016/j.nanoen.2019.01.002

Wang S, Wang ZL, Yang Y, A, (2016) One-structure-based hybridized nanogenerator for scavenging mechanical and thermal energies by triboelectric–piezoelectric–pyroelectric effects. Adv Mater 28:2881–2887. https://doi.org/10.1002/adma.201505684

Sun C, Shi J, Bayerl DJ, Wang X (2011) PVDF microbelts for harvesting energy from respiration. Energy Environ Sci 4:4508–4512. https://doi.org/10.1039/C1EE02241E

Xu C, Song Y, Han M, Zhang H (2021) Portable and wearable self-powered systems based on emerging energy harvesting technology. Microsyst Nanoeng 7:25. https://doi.org/10.1038/s41378-021-00248-z

Wang DW, Mo JL, Wang XF, Ouyang H, Zhou ZR (2018) Experimental and numerical investigations of the piezoelectric energy harvesting via friction-induced vibration. Energy Convers Manag 171:1134–1149. https://doi.org/10.1016/J.ENCONMAN.2018.06.052

Yan J, Jeong YG (2016) High performance flexible piezoelectric nanogenerators based on BaTiO3 nanofibers in different alignment modes. ACS Appl Mater Interfaces 8:15700–15709. https://doi.org/10.1021/acsami.6b02177

Park K-I, Jeong CK, Ryu J, Hwang G-T, Lee KJ (2013) Flexible and large-area nanocomposite generators based on lead zirconate titanate particles and carbon nanotubes. Adv Energy Mater 3:1539–1544. https://doi.org/10.1002/aenm.201300458

Chung SY, Kim S, Lee J-H, Kim K, Kim S-W, Kang C-Y, Yoon S-J, Kim YS (2012) All-solution-processed flexible thin film piezoelectric nanogenerator. Adv Mater 24:6022–6027. https://doi.org/10.1002/adma.201202708

Koka A, Sodano HA (2014) A low-frequency energy harvester from ultralong, vertically aligned BaTiO3 nanowire arrays. Adv Energy Mater 4:1301660. https://doi.org/10.1002/aenm.201301660

He Z, Rault F, Lewandowski M, Mohsenzadeh E, Salaün F (2021) Electrospun PVDF nanofibers for piezoelectric applications: a review of the influence of electrospinning parameters on the β phase and crystallinity enhancement. Polymers (Basel). https://doi.org/10.3390/polym13020174

Yuan X, Gao X, Shen X, Yang J, Li Z, Dong S (2021) A 3D-printed, alternatively tilt-polarized PVDF-TrFE polymer with enhanced piezoelectric effect for self-powered sensor application. Nano Energy 85:105985. https://doi.org/10.1016/J.NANOEN.2021.105985

Wang X, Ling X, Hu Y, Hu X, Zhang Q, Sun K, **ang Y (2022) Electronic skin based on PLLA/TFT/PVDF-TrFE array for multi-functional tactile sensing and visualized restoring. Chem Eng J 434:134735. https://doi.org/10.1016/j.cej.2022.134735

Gu L, Liu J, Cui N, Xu Q, Du T, Zhang L, Wang Z, Long C, Qin Y (2020) Enhancing the current density of a piezoelectric nanogenerator using a three-dimensional intercalation electrode. Nat Commun 11:1–9. https://doi.org/10.1038/s41467-020-14846-4

Mokhtari F, Spinks GM, Fay C, Cheng Z, Raad R, ** J, Foroughi J (2020) Wearable electronic textiles from nanostructured piezoelectric fibers. Adv Mater Technol. https://doi.org/10.1002/admt.201900900

Chen X, Han X, Shen Q-D (2017) PVDF-based ferroelectric polymers in modern flexible electronics. Adv Electron Mater 3:1600460. https://doi.org/10.1002/aelm.201600460

A.L. Moore (2006) 3-Fluoroelastomer Monomers. In: A.L.B.T.-F.H. Moore (Ed.), Plastics Design Library, William Andrew Publishing, Norwich, NY, pp 25–36. https://doi.org/10.1016/B978-081551517-3.50006-X

Li J, Long Y, Yang F, Wang X (2020) Degradable piezoelectric biomaterials for wearable and implantable bioelectronics. Curr Opin Solid State Mater Sci 24:100806. https://doi.org/10.1016/j.cossms.2020.100806

Liu F, Hashim NA, Liu Y, Abed MRM, Li K (2011) Progress in the production and modification of PVDF membranes. J Memb Sci 375:1–27. https://doi.org/10.1016/j.memsci.2011.03.014

Sun Y, Ma Z, Xu X, Liu X, Liu L, Huang G, Liu L, Wang H, Song P (2020) Grafting lignin with bioderived polyacrylates for low-cost, ductile, and fully biobased poly(lactic acid) composites. ACS Sustain Chem Eng 8:2267–2276. https://doi.org/10.1021/acssuschemeng.9b06593

Balla E, Daniilidis V, Karlioti G, Kalamas T, Stefanidou M, Bikiaris ND, Vlachopoulos A, Koumentakou I, Bikiaris DN (2021) Poly(lactic acid): a versatile biobased polymer for the future with multifunctional properties—from monomer synthesis. Polymers, Polymerization Techniques and Molecular Weight Increase to PLA Applications. https://doi.org/10.3390/polym13111822

Broadhurst MG, Davis GT, McKinney JE, Collins RE (1978) Piezoelectricity and pyroelectricity in polyvinylidene fluoride—a model. J Appl Phys 49:4992–4997. https://doi.org/10.1063/1.324445

Yu Y, **ong H, **ao J, Qian X, Leng X, Wei Z, Li Y (2019) High molecular weight unsaturated copolyesters derived from fully biobased trans-β-hydromuconic acid and fumaric acid with 1,4-butanediol: synthesis and thermomechanical properties. ACS Sustain Chem Eng 7:6859–6869. https://doi.org/10.1021/acssuschemeng.8b06334

Wunschik DS, Ingenbosch KN, Zähres M, Horst J, Mayer C, Jäger M, Strehmel V, Dornbusch M, Hoffmann-Jacobsen K (2018) Biocatalytic and solvent-free synthesis of a bio-based biscyclocarbonate. Green Chem 20:4738–4745. https://doi.org/10.1039/C8GC02267D

Menager C, Guigo N, Vincent L, Sbirrazzuoli N (2020) Polymerization kinetic pathways of epoxidized linseed oil with aliphatic bio-based dicarboxylic acids. J Poly Sci 58:1717–1727. https://doi.org/10.1002/pol.20200118

Wang G, Jiang M, Zhang Q, Wang R, Liang Q, Zhou G (2019) New bio-based copolyesters derived from 1,4-butanediol, terephthalic acid and 2,5-thiophenedicarboxylic acid: synthesis, crystallization behavior, thermal and mechanical properties. Polym Test 75:213–219. https://doi.org/10.1016/j.polymertesting.2019.02.020

Fukada E (1998) New piezoelectric polymers. Jpn J Appl Phys 37:2775–2780. https://doi.org/10.1143/jjap.37.2775

W.-F. Su (2013) Structure morphology flow of polymer BT - principles of polymer design and synthesis. In: W.-F. Su (Ed.), Springer Berlin Heidelberg, Berlin, Heidelberg, pp 27–59. https://doi.org/10.1007/978-3-642-38730-2_3.

Desai SD, Emanuel AL, Sinha VK (2003) Biomaterial based polyurethane adhesive for bonding rubber and wood joints. J Polym Res 10:275–281. https://doi.org/10.1023/B:JPOL.0000004630.77120.bb

Hu X, Kang H, Li Y, Li M, Wang R, Xu R, Qiao H, Zhang L (2015) Direct copolycondensation of biobased elastomers based on lactic acid with tunable and versatile properties. Polym Chem 6:8112–8123. https://doi.org/10.1039/c5py01332a

Fernández J, Meaurio E, Chaos A, Etxeberria A, Alonso-Varona A, Sarasua JR (2013) Synthesis and characterization of poly (l-lactide/ε-caprolactone) statistical copolymers with well resolved chain microstructures. Polymer (Guildf) 54:2621–2631. https://doi.org/10.1016/j.polymer.2013.03.009

Vinogradov A, Holloway F (1999) Electro-mechanical properties of the piezoelectric polymer PVDF. Ferroelectrics 226:169–181. https://doi.org/10.1080/00150199908230298

Hu X, Ding Z, Fei L, **ang Y, lin Y (2019) Wearable piezoelectric nanogenerators based on reduced graphene oxide and in situ polarization-enhanced PVDF-TrFE films. J Mater Sci 54:6401–6409. https://doi.org/10.1007/s10853-019-03339-5

Acknowledgements

This work was supported by Start-up Funding of University of Electronic Science and Technology of China (Y030212059003040) and Chinesisch-Deutsche Zentrum für Wissenschaftsförderung, China (GZ 1697).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Kevin Jones.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Zhang, Q., Zhu, H. et al. A highly efficient piezoelectric elastomer with a green product cycle from fabrication to degradation. J Mater Sci 58, 4840–4852 (2023). https://doi.org/10.1007/s10853-023-08349-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08349-y