Abstract

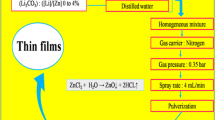

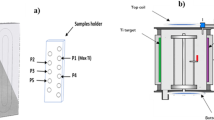

Doped TiAlN thin films are gaining unprecedented attention in recent times due to their functionality and tuneable properties to meet specific demands. The present article focuses on the influence of phosphorous-doped TiAlN thin films deposited using high-power impulse magnetron sputtering. Thin films of different elemental compositions of Ti, Al, and P were sputtered on AISI 5206 steel. The thin film cross-sectional morphology and architecture revealed dense and columnar structures. It was indicated that the (111) diffraction peaks in the XRD pattern shifted to higher angles, while the transverse optics (TO)/longitudinal optics (LO) frequency in the optic phonons region of Raman spectra shifted to the right with the modulation wavelength as the Al and P compositions increase. The elementary composition influences the mechanical properties with the maximum hardness of 28 GPa, and adhesion strength of 15 N attained in thin film with the highest Al and P content. The corrosion rate in all the thin films was reduced by at least two orders of magnitude compared with the uncoated samples. The addition of P increases the corrosion resistance of TiAl(P)N thin films.

Graphical abstract

Similar content being viewed by others

References

Koch GH, Brongers MPH, Thompson NG, et al (2002) No title. Corrosion cost and preventive strategies in the United States

Yu H, Zhang Z, Han M (2012) Metal corrosion for nanofabrication. Small 8:2621–2635

de Fatima Montemor M (2014) Functional and smart coatings for corrosion protection: a review of recent advances. Surf Coat Technol 258:17–37

Veprek S, Veprek-heijman M (2008) Industrial applications of superhard nanocomposite coatings. Surf Coat Technol 202:5063–5073. https://doi.org/10.1016/j.surfcoat.2008.05.038

Maurya DK, Sardarinejad A, Alameh K (2014) Recent developments in R.F. magnetron sputtered thin films for pH sensing applications: an overview. Coatings 4:756–771. https://doi.org/10.3390/coatings4040756

Abegunde OO, Akinlabi ET, Oladijo OP et al (2019) Overview of thin film deposition techniques. AIMS Mater Sci 6:174–199

Alami J, Bolz S, Sarakinos K (2009) High power pulsed magnetron sputtering: fundamentals and applications. J Alloys Compd 483:530–534. https://doi.org/10.1016/j.jallcom.2008.08.104

Sarakinos K, Alami J, Konstantinidis S (2010) High power pulsed magnetron sputtering: a review on scientific and engineering state of the art. Surf Coat Technol 204:1661–1684

Chen Y-I, Lin K-Y, Wang H-H, Lin K-C (2014) Thermal stability of TaN, CrTaN, TaSiN, and CrTaSiN hard coatings in oxygen-containing atmospheres. Surf Coat Technol 259:159–166

El-Hossary FM, El-Rahman AMA, Raaif M, Ghareeb DA (2016) Properties of TiAlN coating deposited by MPIIID on TiN substrates. Appl Phys A 122:1–11

Ananthakumar R, Subramanian B, Kobayashi A, Jayachandran M (2012) Electrochemical corrosion and materials properties of reactively sputtered TiN/TiAlN multilayer coatings. Ceram Int 38:477–485

Greczynski G, Lu J, Jensen J et al (2014) A review of metal-ion-flux-controlled growth of metastable TiAlN by HIPIMS/DCMS co-sputtering. Surf Coat Technol 257:15–25. https://doi.org/10.1016/j.surfcoat.2014.01.055

Pfeiler M, Zechner J, Penoy M et al (2009) Improved oxidation resistance of TiAlN coatings by do** with Si or B. Surf Coat Technol 203:3104–3110. https://doi.org/10.1016/J.SURFCOAT.2009.03.036

Barshilia HC, Niranjan K, Srinivas G et al (2022) On the thermal stability and performance evaluation of Si doped transition metal nitride/oxide nanolayered multilayer-based spectrally selective absorber for high-temperature photothermal applications. Sol Energy Mater Sol Cells 241:111746–111757. https://doi.org/10.1016/J.SOLMAT.2022.111746

Zhou J, Hu C, Zhang J et al (2021) Effect of B-do** on the mechanical properties, thermal stability and oxidation resistance of TiAlN coatings. Int J Refract Met Hard Mater 98:105531–105540. https://doi.org/10.1016/J.IJRMHM.2021.105531

Baker MA, Klose S, Rebholz C et al (2002) Evaluating the microstructure and performance of nanocomposite PVD TiAlBN coatings. Surf Coat Technol 151–152:338–343. https://doi.org/10.1016/S0257-8972(01)01657-7

Liang M, Wang C, Liang C et al (2021) The effect of Cr and Cr-Ni do** on the properties of TiAlN coatings. J Phys Conf Ser 2044(1):012077–012084

Danek M, Fernandes F, Cavaleiro A, Polcar T (2017) Influence of Cr additions on the structure and oxidation resistance of multilayered TiAlCrN films. Surf Coat Technol 313:158–167. https://doi.org/10.1016/J.SURFCOAT.2017.01.053

Tillmann W, Grisales D, Echavarría AM et al (2022) Effect of Ag do** on the microstructure and electrochemical response of TiAlN coatings deposited by DCMS/HiPIMS magnetron sputtering. J Mater Eng Perform 31:3811–3825. https://doi.org/10.1007/s11665-021-06467-9

Koller CM, Hollerweger R, Sabitzer C et al (2014) Thermal stability and oxidation resistance of arc evaporated TiAlN, TaAlN, TiAlTaN, and TiAlN/TaAlN coatings. Surf Coat Technol 259:599–607

Rachbauer R, Blutmager A, Holec D, Mayrhofer PH (2012) Effect of Hf on structure and age hardening of Ti–Al-N thin films. Surf Coat Technol 206:2667–2672

Braic V, Zoita CN, Balaceanu M et al (2010) TiAlN/TiAlZrN multilayered hard coatings for enhanced performance of HSS drilling tools. Surf Coat Technol 204:1925–1928

Tillmann W, Momeni S, Hoffmann F (2013) A study of mechanical and tribological properties of self-lubricating TiAlVN coatings at elevated temperatures. Tribol Int 66:324–329

Yang K, **an G, Zhao H et al (2015) Effect of Mo content on the structure and mechanical properties of TiAlMoN films deposited on WC–Co cemented carbide substrate by magnetron sputtering. Int J Refract Metals Hard Mater 52:29–35

Wang M, Ma R, Du A et al (2020) Corrosion resistance of black phosphorus nanosheets composite phosphate coatings on Q235 steel. Mater Chem Phys 250:123056–123066. https://doi.org/10.1016/j.matchemphys.2020.123056

Rofagha R, Erb U, Ostrander D et al (1993) The effects of grain size and phosphorus on the corrosion of nanocrystalline Ni-P alloys. Nanostruct Mater 2:1–10

Lo P-H, Tsai W-T, Lee J-T, Hung M-P (1994) Role of phosphorus in the electrochemical behavior of electroless Ni-P alloys in 3.5 wt.% NaCl solutions. Surf Coat Technol 67:27–34

Hashimoto K, Zhang BP, Im BM et al (1997) The role of phosphorus in enhancing corrosion resistance of amorphous alloys. Sci Rep Res Inst Tohoku Univ Ser A Japan 43:145–151

Makha M, Ghailane A, Larhlimi H et al (2020) Phosphorus containing coatings: technologies and applications. ChemistrySelect 5:6570–6584

Królikowski A, Butkiewicz P (1993) Anodic behavior of Ni P alloys studied by impedance spectroscopy. Electrochim Acta 38:1979–1983

Sribalaji M, Arunkumar P, Babu KS, Keshri AK (2015) Crystallization mechanism and corrosion property of electroless nickel phosphorus coating during intermediate temperature oxidation. Appl Surf Sci 355:112–120

Millet F, Auvergne R, Caillol S et al (2014) Improvement of corrosion protection of steel by incorporation of a new phosphonated fatty acid in a phosphorus-containing polymer coating obtained by UV curing. Prog Org Coat 77:285–291

Krupa D, Baszkiewicz J, Kozubowski JA et al (2002) Effect of phosphorus-ion implantation on the corrosion resistance and biocompatibility of titanium. Biomaterials 23:3329–3340

Ramezani-Varzaneh HA, Allahkaram SR, Isakhani-Zakaria M (2014) Effects of phosphorus content on corrosion behavior of trivalent chromium coatings in 3.5 wt.% NaCl solution. Surf Coat Technol 244:158–165

Guo L, Huang Q, Zhang C et al (2021) Study on the formation of Mn-P coatings with significant corrosion resistance on Q235 carbon steels by adjusting the ratio of phosphorus to manganese. Corros Sci 178:108960–108974

Ghailane A, Makha M, Larhlimi H, Alami J (2020) Design of hard coatings deposited by HiPIMS and dcMS. Mater Lett 280:128540–128545

Alami J, Eklund P, Andersson JM et al (2007) Phase tailoring of Ta thin films by highly ionized pulsed magnetron sputtering. Thin Solid Films 515:3434–3438

Alami J, Stranak V, Herrendorf A-P et al (2015) Design of magnetic field configuration for controlled discharge properties in highly ionized plasma. Plasma Sources Sci Technol 24:045016–045026

Ghailane A, Larhlimi H, Tamraoui Y et al (2020) The effect of magnetic field configuration on structural and mechanical properties of TiN coatings deposited by HiPIMS and dcMS. Surf Coat Technol 404:126572–126582

Ratova M, West GT, Kelly PJ (2014) Optimisation of HiPIMS photocatalytic titania coatings for low temperature deposition. Surf Coat Technol 250:7–13

Houska J, Kolenaty D, Vlcek J, Cerstvy R (2018) Properties of thermochromic VO2 films prepared by HiPIMS onto unbiased amorphous glass substrates at a low temperature of 300° C. Thin Solid Films 660:463–470

Fager H, Tengstrand O, Lu J et al (2017) Low-temperature growth of dense and hard Ti0.41Al0.51Ta0.08N films via hybrid HIPIMS/DC magnetron co-sputtering with synchronized metal-ion irradiation. J Appl Phys 121:171902–171909

Magnfält D, Abadias G, Sarakinos K (2013) Atom insertion into grain boundaries and stress generation in physically vapor deposited films. Appl Phys Lett 103:051910–051914

Abegunde OO, Makha M, Machkih K et al (2022) Comparative study on the influence of reactive gas flow rate on the growth and Properties of P-doped TiAlN coatings prepared by DcMS and HiPIMS. J Bio Tribocorros 8:1–15. https://doi.org/10.1007/s40735-022-00672-2

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7:1564–1583

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mater Res 19:3–20

Mitin DM, Serdobintsev AA (2017) Effect of scattering of sputtered atoms on the growth rate of films fabricated by magnetron sputtering. Tech Phys Lett 43:814–816

Lundin D, Sarakinos K (2012) An introduction to thin film processing using high-power impulse magnetron sputtering. J Mater Res 27:780–792

Uny F, Blanquet E, Schuster F, Sanchette F (2018) Ti-Al-N-based hard coatings: Thermodynamical background, CVD deposition, and properties. A review. In: Coatings and thin-film technologies

Li X, Bakhit B, Joesaar MPJ et al (2021) Toward energy-efficient physical vapor deposition: routes for replacing substrate heating during magnetron sputter deposition by employing metal ion irradiation. Surf Coat Technol 415:127639–127640

Ipaz L, Aperador W, Caicedo J et al (2012) A practical application of X-ray spectroscopy in Ti-Al-N and Cr-Al-N thin films. In: X-ray spectroscopy, pp 21–38

Elmkhah H, Zhang TF, Abdollah-Zadeh A et al (2016) Surface characteristics for the TiAlN coatings deposited by high power impulse magnetron sputtering technique at the different bias voltages. J Alloys Compd 688:820–827

Zhou H, Zheng J, Gui B et al (2017) AlTiCrN coatings deposited by hybrid HIPIMS/DC magnetron co-sputtering. Vacuum 136:129–136

Wang Z, Zhang D, Ke P et al (2015) Influence of substrate negative bias on structure and properties of TiN coatings prepared by hybrid HIPIMS method. J Mater Sci Technol 31:37–42. https://doi.org/10.1016/j.jmst.2014.06.002

Das S, Guha S, Ghadai R et al (2017) Structural and mechanical properties of CVD deposited titanium aluminium nitride (TiAlN) thin films. Appl Phys A 123:412

Chen L, Wang SQ, Du Y et al (2010) Machining performance of Ti–Al–Si–N coated inserts. Surf Coat Technol 205:582–586

Zhu S, **ao L, Cortie MB (2016) Surface enhanced Raman spectroscopy on metal nitride thin films. Vib Spectrosc 85:146–148

Barshilia HC, Rajam KS (2005) A Raman-scattering study on the interface structure of nanolayered Ti Al N/Ti N and Ti N/Nb N multilayer thin films grown by reactive dc magnetron sputtering. J Appl Phys 98:014311–014320

** Y, Bai Y, Gao K et al (2018) Residual stress and microstructure effects on mechanical, tribological and electrical properties of TiN coatings on 304 stainless steel. Ceram Int 44:15851–15858

Ali R, Sebastiani M, Bemporad E (2015) Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater Des 75:47–56

Sangiovanni DG, Chirita V, Hultman L (2012) Toughness enhancement in TiAlN-based quarternary alloys. Thin Solid Films 520:4080–4088

Kataria S, Srivastava SK, Kumar P et al (2012) Nanocrystalline TiN coatings with improved toughness deposited by pulsing the nitrogen flow rate. Surf Coat Technol 206:4279–4286

Leyland A, Matthews A (2000) On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246:1–11

Zhang S, Sun D, Fu Y, Du H (2005) Toughness measurement of thin films: a critical review. Surf Coat Technol 198:74–84

Cheng Y-T, Cheng C-M (1998) Relationships between hardness, elastic modulus, and the work of indentation. Appl Phys Lett 73:614–616

Kumar S, Maity SR, Patnaik L (2020) Friction and tribological behavior of bare nitrided, TiAlN and AlCrN coated MDC-K hot work tool steel. Ceram Int 46:17280–17294. https://doi.org/10.1016/J.CERAMINT.2020.04.015

Kumar S, Maity SR, Patnaik L (2022) Morphology and wear behavior of monolayer TiAlN and composite AlCrN/TiAlN-coated plasma-nitrided DAC-10 tool steel. Arab J Sci Eng. https://doi.org/10.1007/s13369-022-06711-x

Sui X, Li G, Qin X et al (2016) Relationship of microstructure, mechanical properties and titanium cutting performance of TiAlN/TiAlSiN composite coated tool. Ceram Int 42:7524–7532

Sveen S, Andersson JM, M’saoubi R, Olsson M (2013) Scratch adhesion characteristics of PVD TiAlN deposited on high speed steel, cemented carbide and PCBN substrates. Wear 308:133–141

Simsir M, Palaci Y, Özer A (2021) A comparative study of hardness/scratch/wear properties of TiCN and TiAlN coatings on DIN 1.2842 steel by CA-PVD method. J Aust Ceram Soc 57:1–11

Chen J (2012) Indentation-based methods to assess fracture toughness for thin coatings. J Phys D Appl Phys 45:203001–203015

Chen J, Bull SJ (2010) Approaches to investigate delamination and interfacial toughness in coated systems: an overview. J Phys D Appl Phys 44:034001–034020

Datta T, Pathak AD, Basak S et al (2021) Fractal behavior of surface oxide crack patterns on AISI 4140 high-strength low-alloy steel exposed to the simulated offshore environment. Appl Surf Sci Adv 5:100110–100118

Kahyarian A, Schumaker A, Brown B, Nesic S (2017) Acidic corrosion of mild steel in the presence of acetic acid: mechanism and prediction. Electrochim Acta 258:639–652

Zhao X, Cai W, Zhao L (2002) Corrosion behavior of phosphorus ion-implanted Ni50.6Ti49.4 shape memory alloy. Surf Coat Technol 155:236–238

Ghailane A, Oluwatosin AO, Larhlimi H et al (2021) Titanium nitride, TiXN (1-X), coatings deposited by HiPIMS for corrosion resistance and wear protection properties. Appl Surf Sci 574:151635–151646

Stansbury EE, Buchanan RA (2000) Fundamentals of electrochemical corrosion. ASM International, Almere

Obeydavi A, Shafyei A, Rezaeian A et al (2020) Microstructure, mechanical properties and corrosion performance of Fe44Cr15Mo14Co7C10B5Si5 thin film metallic glass deposited by DC magnetron sputtering. J Non Cryst Solids 527:119718–119735

Lu F, Song B, He P et al (2017) Electrochemical impedance spectroscopy (EIS) study on the degradation of acrylic polyurethane coatings. RSC Adv 7:13742–13748

Ding Z, Li Y-Y, Xu M-R et al (2020) Electrochemical properties of aluminum tripolyphosphate modified chemically bonded phosphate ceramic anticorrosion coating. Constr Build Mater 251:118874–118884. https://doi.org/10.1016/j.conbuildmat.2020.118874

NACE International (1999) Standard recommended practice: preparation, installation, analysis, and interpretation of corrosion coupons in oilfield operations. NACE International, Houston

Panjan P, Drnovšek A, Gselman P et al (2019) Influence of growth defects on the corrosion resistance of sputter-deposited TiAlN Hard coatings. Coatings. https://doi.org/10.3390/coatings9080511

Jehn HA (2000) Improvement of the corrosion resistance of PVD hard coating–substrate systems. Surf Coat Technol 125:212–217. https://doi.org/10.1016/S0257-8972(99)00551-4

Panjan P, Čekada M, Panjan M et al (2012) Surface density of growth defects in different PVD hard coatings prepared by sputtering. Vacuum 86:794–798. https://doi.org/10.1016/J.VACUUM.2011.07.013

Wang X, Chen Y, Niu G (2018) The study on corrosion resistance of high-strength spring steel. Corros Eng Sci Technol 53:54–64

Chen D, Yen M, Lin P et al (2014) A corrosion sensor for monitoring the early-stage environmental corrosion of A36 carbon steel. Materials 7:5746–5760

Acknowledgements

The authors would like to acknowledge the financial contribution of OCP.SA Morocco.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abegunde, O.O., Makha, M., Machkih, K. et al. Structural, mechanical and corrosion resistance of phosphorus-doped TiAlN thin film. J Mater Sci 57, 19107–19130 (2022). https://doi.org/10.1007/s10853-022-07785-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07785-6