Abstract

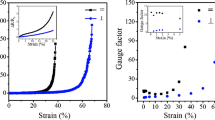

Alloying technique as an ancient and practical instrument has been a diverse fabricator for desirable properties of materials. Herein, utilizing the alloying engineering, we have developed a two-step process for hybrid graphene-NiW nanofibers (Gr-NiW NFs) transparent electrodes. Further analysis reveals that alloying NiW NFs significantly improve their mechanical performance, reducing the growth temperature of graphene down to ~ 700 °C or below, which is far less than that of ~ 1000 °C for graphene grown on Cu or Pt. More importantly, such Gr-NiW network has exhibited excellent transmittance in a broad wavelength and remarkable conductivity, which, in turn, could be tailored by the growth temperature and the W content. A high transmittance (84.2% at 550 nm) and low sheet resistance (125.4 Ohm/square) were observed at Ni NFs with 5 wt% W. The combination of excellent conductivity, high transparency and mechanical tunability makes it a promising candidate for wearable electronics and optoelectronics. Finally, an all-nanofiber-based pressure sensor on sandwiched Gr-NiW/P(VDF-TrFE)/Gr-NiW NFs was demonstrated, with high sensitivity (0.61 mV kPa−1) and excellent operation stability. This work offers deep insights into the development of transparent graphene-based electrodes via alloy engineering.

Similar content being viewed by others

References

Kou H, Lu J, Li Y (2014) High-strength and high-ductility nanostructured and amorphous metallic materials. Adv Mater 26:5518–5524

Wu H, Fan G (2020) An overview of tailoring strain delocalization for strength-ductility synergy. Prog Mater Sci 113:100675

George EP, Raabe D, Ritchie RO (2019) High-entropy alloys. Nat Rev Mater 4:515–534

Li Z, Zhao S, Ritchie RO, Meyers MA (2019) Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog Mater Sci 102:296–345

Papageorgiou DG, Kinloch IA, Young RJ (2017) Mechanical properties of graphene and graphene-based nanocomposites. Prog Mater Sci 90:75–127

Castro Neto AH, Guinea F, Peres NMR et al (2009) The electronic properties of graphene. Rev Mod Phys 81:109–162

Nair RR, Blake P, Grigorenko AN et al (2008) Fine structure constant defines visual transparency of graphene. Science 320:1308–1308

Deng B, Liu Z, Peng H (2019) Toward mass production of CVD graphene films. Adv Mater 31:1800996

Zhu MM, Wu J, Du ZH et al (2015) A wafer-scale graphene and ferroelectric multilayer for flexible and fast-switched modulation applications. Nanoscale 7:14730–14737

**ao D, Zhu M, Wang Q et al (2020) A flexible and ultra-broadband terahertz wave absorber based on graphene–vertically aligned carbon nanotube hybrids. J Mater Chem C 8:7244–7252

Li X, Cai W, An J et al (2009) Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324:1312–1314

Wu T, Zhang X, Yuan Q et al (2016) Fast growth of inch-sized single-crystalline graphene from a controlled single nucleus on Cu–Ni alloys. Nat Mater 15:43–47

Huang M, Bakharev PV, Wang Z-J et al (2020) Large-area single-crystal AB-bilayer and ABA-trilayer graphene grown on a Cu/Ni(111) foil. Nat Nanotechnol 15:289–295

Gao L, Ren W, Xu H et al (2012) Repeated growth and bubbling transfer of graphene with millimetre-size single-crystal grains using platinum. Nat Commun 3:699

Zhang B, Chen B, Wu J et al (2017) The electrochemical response of single crystalline copper nanowires to atmospheric air and aqueous solution. Small 13:1603411

Li X, Lu K (2017) Playing with defects in metals. Nat Mater 16:700–701

Morishita M, Koyama K, Yagi S, Zhang G (2001) Calculated phase diagram of the Ni–Mo–B ternary system. J Alloys Compd 314:212–218

Zhu MM, Wu J, Du ZH et al (2018) Gate voltage and temperature dependent Ti-graphene junction resistance toward straightforward p-n junction formation. J Appl Phys 124:215302

Li D, **a Y (2004) Electrospinning of nanofibers: Reinventing the wheel? Adv Mater 16:1151–1170

Xue J, Wu T, Dai Y, **a Y (2019) Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 119:5298–5415

Ico G, Showalter A, Bosze W et al (2016) Size-dependent piezoelectric and mechanical properties of electrospun P(VDF-TrFE) nanofibers for enhanced energy harvesting. J Mater Chem A 4:2293–2304

Li R, Rao L, Zhang J et al (2021) Novel in-situ electroflotation driven by hydrogen evolution reaction (HER) with polypyrrole (PPy)-Ni-modified fabric membrane for efficient oil/water separation. J Memb Sci 635:119502

You X, Zhang J, Shen L et al (2021) Thermodynamic mechanisms of membrane fouling during filtration of alginate solution in coagulation-ultrafiltration (UF) process in presence of different ionic strength and iron(III) ion concentration. J Memb Sci 635:119532

Wu J, **a M, Li Z et al (2021) Facile preparation of polyvinylidene fluoride substrate supported thin film composite polyamide nanofiltration: effect of substrate pore size. J Memb Sci 638:119699

Tay RY, Park HJ, Lin J et al (2018) Concentric and spiral few-layer graphene: growth driven by interfacial nucleation vs screw dislocation. Chem Mater 30:6858–6866

Zhu MM, Du ZH, Yin ZY et al (2016) Low-temperature in situ growth of graphene on metallic substrates and its application in anticorrosion. ACS Appl Mater Interfaces 8:502–510

Lander JJ, Kern HE, Beach AL (1952) Solubility and diffusion coefficient of carbon in nickel: reaction rates of nickel-carbon alloys with barium oxide. J Appl Phys 23:1305–1309

Hu X, Hemmat Z, Majidi L et al (2020) Controlling nanoscale thermal expansion of monolayer transition metal dichalcogenides by alloy engineering. Small 16:1905892

Hu L, Kim HS, Lee J et al (2010) Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 4:2955–2963

Gruner G, Angeles L, Gong J et al (2007) Electrowetting devices with transparent single-walled carbon nanotube electrodes Electrowetting devices with transparent single-walled carbon nanotube electrodes. Appl Phys Lett 90:093124

Zhu Y, Lu W, Sun Z et al (2011) High throughput preparation of large area transparent electrodes using non-functionalized graphene nanoribbons. Chem Mater 23:935–939

Sa K, Mahanandia P (2019) Conducting reduced graphene oxide film as transparent electrode. Thin Solid Films 692:137594

Kim KS, Zhao Y, Jang H et al (2009) Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457:706–710

Kholmanov IN, Magnuson CW, Piner R et al (2015) Optical, electrical, and electromechanical properties of hybrid graphene/carbon nanotube films. Adv Mater 27:3053–3059

Yousry YM, Yao K, Mohamed AM et al (2020) Theoretical model and outstanding performance from constructive piezoelectric and triboelectric mechanism in electrospun PVDF fiber film. Adv Funct Mater 30:1910592

Surmenev RA, Orlova T, Chernozem RV et al (2019) Hybrid lead-free polymer-based nanocomposites with improved piezoelectric response for biomedical energy-harvesting applications: a review. Nano Energy 62:475–506

Zhu MM, Chng SS, Cai WF et al (2020) Piezoelectric polymer nanofibers for pressure sensors and their applications in human activity monitoring. RSC Adv 10:21887–21894

Persano L, Dagdeviren C, Su Y et al (2013) High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidenefluoride-co-trifluoroethylene). Nat Commun 4:1633

Peng X, Dong K, Ye C et al (2020) A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Sci Adv 6:eaba9624

Acknowledgements

The authors sincerely acknowledge Dr. Weifan Cai and Dr. Zehui Du for their help in sensor testing and discussion.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Handling Editor: Catalin Croitoru.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, M., Zhao, A., Wei, C. et al. Hybrid graphene-NiW nanofiber transparent electrodes for all-nanofiber-based pressure sensor. J Mater Sci 57, 2627–2635 (2022). https://doi.org/10.1007/s10853-021-06702-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06702-7