Abstract

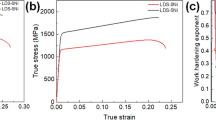

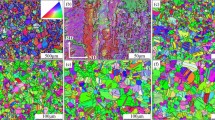

In this paper, the effects of Nb contents (0.05 ~ 0.50wt%) and hot rolling temperatures (1000 ~ 1200 °C) on microstructure and mechanical properties of high-silicon electrical steel were studied. The results show that adding a small amount of Nb can significantly improve the plasticity of high-silicon electrical steel. Compared with the specimens without Nb, the three-point bending load–deflection curves of the alloys with Nb contents of 0.05 ~ 0.50wt% after warm rolling showed obvious plastic stage. The average fracture deflection increases from 4.5 to 9.9 mm with the Nb content increasing from 0.05 to 0.50wt%. When the hot rolling temperature is 1000 °C, the Nb-containing high-silicon electrical steel has a layered microstructure along the thickness direction. The surface layer is equiaxed grains with dynamic recrystallization, while the center of the thickness is a long strip structure with dynamic recovery. The mechanism of Nb microalloying to improve plasticity includes three aspects: Firstly, the layered structure hinders the propagation of cracks and delays the progress of fracture; secondly, a large number of fine Nb precipitates will hinder the grain growth and refine the grains; thirdly, the formation of the Nb-precipitated phase destroys the ordered rearrangement between adjacent Fe and Si atoms in the matrix, inhibits the ordered transformation and reduces the ordered degree of high-silicon electrical steel. When the hot rolling temperature is increased to 1100 °C or above, the layered structure disappears, the grain coarsens obviously, and the plasticity of the warm-rolled specimens is significantly reduced.

Similar content being viewed by others

References

Komatsubara M, Sadahiro K, Kondo O, Honda A (2002) Newly developed electrical steel for high-frequency use. J Magn Magn Mater 242:212–215. https://doi.org/10.1016/S0304-8853(01)01164-7

Oda Y, Kohno M, Honda A (2008) Recent development of non-oriented electrical steel sheet for automobile electrical devices. J Magn Magn Mater 320(20):2430–2435. https://doi.org/10.1016/j.jmmm.2008.03.054

Ouyang GY, Chen X, Liang YF, Macziewski C, Cui J (2019) Review of Fe-6.5 wt%Si high silicon steel—a promising soft magnetic material for sub-kHz application. J Magn Magn Mater 481:234–250. https://doi.org/10.1016/j.jmmm.2019.02.089

Ros-Yanez T, Ruiz D, Barros J, Houbaert Y, Colas R (2007) Study of deformation and aging behaviour of iron-silicon alloys. Mater Sci Eng A 447(1–2):27–34. https://doi.org/10.1016/j.msea.2006.10.075

Yu JH, Shin JS, Bae JS, Lee ZH, Lee TD, Lee HM, Lavernia EJ (2001) The effect of heat treatments and Si contents on B2 ordering reaction in high-silicon steels. Mater Sci Eng A307(1–2):29–34. https://doi.org/10.1016/S0921-5093(00)01960-2

Viala B, Degauque J, Fagot M, Baricco M, Ferrara E, Fiorillo F (1996) Study of the brittle behaviour of annealed Fe-6.5wt% Si ribbons produced by planar flow casting. Mater Sci Eng 212(1):62–68. https://doi.org/10.1016/0921-5093(96)10188-X

Haiji H, Okada K, Hiratani T, Abe M, Ninomiya M (1996) Magnetic properties and workability of 6.5% Si steel sheet. J Magn Magn Mater 160:109–114. https://doi.org/10.1016/0304-8853(96)00128-X

Okada K, Yamaji T, Kasai K (1996) Basic investigation of CVD metahod for manufacturing 6.5% Si steel sheet. ISIJ Int 36(6):706–713. https://doi.org/10.2355/isi**ternational.36.706

Li HZ, Liu HT, Liu ZY, Lu HH, Song HY, Wang GD (2014) Characterization of microstructure, texture and magnetic properties in twin-roll casting high silicon non-oriented electrical steel. Mater Charact 88:1–6. https://doi.org/10.1016/j.matchar.2013.11.014

Li HZ, Liu HT, Liu Y et al (2014) Effects of warm temper rolling on microstructure, texture and magnetic properties of strip-casting 6.5wt% Si electrical steel. J Magn Magn Mater 370:6–12. https://doi.org/10.1016/j.jmmm.2014.06.053

Wang XL, Liu ZY, Li HZ, Wang GD (2017) Microstructure evolution in warm-rolled and cold-rolled strip cast 6.5wt% Si steel thin sheet and its influence on magnetic properties. J Magn Magn Mater 433:8–16. https://doi.org/10.1016/j.jmmm.2017.02.057

Arai K, Tsuya N (1980) Ribbon-form silicon-iron alloy containing around 6.5 percent silicon. IEEE Trans Magn 16(1):126–129. https://doi.org/10.1109/TMAG.1980.1060560

Tsuya N, Arai KI (1979) Magnetostriction of ribbon-form amorphous and crystalline ferromagnetic alloys. J Appl Phys 50(B3):1658–1663. https://doi.org/10.1063/1.327229

Liang YF, Ye F, Lin JP, Wang YL, Chen GL (2010) Effect of annealing temperature on magnetic properties of cold rolled high silicon steel thin sheet. J Alloys Compd 491(1–2):268–270. https://doi.org/10.1016/j.jallcom.2009.10.118

Lin JP, Ye F, Chen GL, Wang YL, Liang YF, ** JN, Liu Y (2007) Fabrication technology, microstructures and properties of Fe- 6.5wt.%Si alloy sheets by cold rolling. Front Sci 2:13–26

Fu HD, Zhang ZH, Pan HJ, Mo YK, **e JX (2013) Warm/cold rolling processes for producing Fe-6.5wt% Si electrical steel with columnar grains. Int J Min Metall Mater 20(6):535–540. https://doi.org/10.1007/s12613-013-0762-z

Kim KN, Pan LM, Lin JP, Lin Z, Chen GL (2004) The effect of boron content on the processing for Fe-6.5wt% Si electrical steel sheets. J Magn Magn Mater 277(3):331–336. https://doi.org/10.1016/j.jmmm.2003.11.012

Fu HD, Zhang ZH, Wu XS, **e JX (2013) Effects of boron on microstructure and mechanical properties of Fe-6.5wt.%Si alloy fabricated by directional solidification. Intermetallics 35:67–72. https://doi.org/10.1016/j.intermet.2012.12.005

Fu HD, Zhang ZH, Yang Q, **e JX (2011) Morphology of the boron-rich phase along columnar grain boundary and its effect on the compression crack of Fe-6.5Si-0.05B alloy. Mater Sci Eng A 528(3):1425–1430. https://doi.org/10.1016/j.msea.2010.11.023

Yu X, Zhang ZH, ** on ordered structures and ductility improvement of Fe-6.5wt%Si alloy. Mater Lett 184:294–297. https://doi.org/10.1016/j.matlet.2016.08.074

Yu X, Lin GT, Zhang ZH, **e JX (2020) Electronic structure characteristics of Fe-6.5wt%Si alloy doped with rare earth element and its effect on mechanical properties. J Alloys Compd 843:155916. https://doi.org/10.1016/j.jallcom.2020.155916

Li HZ, Liu HT, Liu ZY, Wang GD (2015) Microstructure, texture evolution and magnetic properties of strip-casting non-oriented 6.5wt.% Si electrical steel doped with cerium. Mater Charact 103:101–106. https://doi.org/10.1016/j.matchar.2015.03.024

Yu X, Zhang ZH, **e JX (2017) Microstructure, ordered structure and warm tensile ductility of Fe-6.5%Si alloy with various Ce content. Acta Metall Sin 53(8):927–936

Yang K, Liang YF, Ye F, Lin JP (2013) Texture evolution of Nb micro-alloyed Fe14Si2 high silicon steel during warm rolling. Acta Metall Sin 49(11):1411. https://doi.org/10.3724/SP.J.1037.2013.00492

Sumit G, Suhrit M (2020) Fracture toughness characteristics of ultrafine grained Nb-Ti stabilized microalloyed and interstitial free steels processed by advanced multiphase control rolling. Mater Charact 159:110003. https://doi.org/10.1016/j.matchar.2019.110003

Li X, Gu KJ, Kang YL, Yu H, Wang KL, Cai KK (2003) Effect of controlled rolling and cooling process parameters on structure of Nb microalloyed high carbon steel. Special Steel 24(4):9–12

Chen SJ, Li LJ, Peng ZW, Huo XD, Gao JX (2020) Strain-induced precipitation in Ti microalloyed steel by two-stage controlled rolling process. J Mater Res Technol 9(6):15759–15770. https://doi.org/10.1016/j.jmrt.2020.11.040

Lin GT, Zhao F, Yu X, Zhang ZH, **e JX (2020) Effect of annealing on microstructure, texture and magnetic properties of Fe-6.5 wt%Si-0.03 wt%Nb alloy. J Magn Magn Mater 504:166699. https://doi.org/10.1016/j.jmmm.2020.166699

Mo YK, Zhang ZH, Pan HJ, **e JX (2016) Improved plasticity and cold-rolling workability of Fe-6.5wt%Si alloy by warm-rolling with gradually decreasing temperature. J Mater Sci Technol 32(5):477–484

Mo YK, Zhang ZH, **e JX, Pan HJ (2016) Effects of recrystallization on the microstructure, ordering and mechanical properties of cold-rolled high silicon electrical steel sheet. Acta Metall Sin 52(11):1363–1371

Li H, Liang YF, Ye F (2016) Evolution of microstructure and ordering in rolling process of Fe-65 mass% Si alloy. J Iron Steel Res Int 23(5):453–458. https://doi.org/10.1016/S1006-706X(16)30072-3

Shi XJ, Liang YF, Liu BB (2019) Serrated flow behavior of hot-rolled Fe-6.5wt.%Si sheet with layered structure. Metals 9(10):1023. https://doi.org/10.3390/met9101023

Yu HY, Ming KS, Wu HC, Yu YX, Bi XF (2018) Ordering suppression and excellent ductility in soft-magnetic Fe-6.5wt%Si sheet by Hf addition. J Alloys Compd 766:186–193. https://doi.org/10.1016/j.jallcom.2018.06.343

Guo JC, Yang Y, Huang YR, Misra RDK (2020) The significance of Ce on hot compression deformation and mechanical behavior of Fe–6.9wt%Si alloy: decrease of order degree and transformation of dislocations. Mater Charact 163:110220. https://doi.org/10.1016/j.matchar.2020.110220

Acknowledgements

This work was supported by National Natural Science Foundation of China (No.52090041) and China Postdoctoral Science Foundation (2019TQ0031).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We state that the work described here has not been published before. It presents original work and is not under consideration for publication anywhere else. The publication has been agreed by all authors. It conforms to the journal’s policy of plagiarism and publication ethics. It does not include any libelous or unlawful statements. The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lin, G., Zhang, Z., Zhao, F. et al. Microstructure and plasticity improvement of Nb-microalloyed high-silicon electrical steel. J Mater Sci 57, 500–516 (2022). https://doi.org/10.1007/s10853-021-06651-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06651-1