Abstract

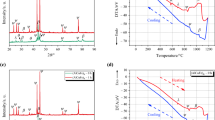

The impact of composition on the tunnel features of hollandite materials for the purpose of radioactive cesium (Cs) immobilization was evaluated. The barium (Ba) to cesium (Cs) ratio was varied in the tunnel sites referred to as the A-site of the hollandite structure. Zinc (Zn) was substituted for titanium (Ti) on the B-site to achieve the targeted stoichiometry with a general formula of BaxCsyZnx+y/2Ti8−x−y/2O16 (0 < x < 1.33; 0 < y <1.33). The tunnel cross-section depended on the average A-site cation radius, while the tunnel length depended on the average B-site cation radius. Substitution of Cs resulted in a phase transition from a monoclinic to a tetragonal structure and an increase in unit cell volume of 1.8% across the compositional range. Cs loss due to thermal evaporation was found to decrease in compositions with higher Cs content. The enthalpies of formation from binary oxides of Zn-doped hollandite measured using high-temperature oxide melt solution calorimetry were strongly negative, indicating thermodynamic stability with respect to their parent oxides. The formation enthalpies became more negative, indicating hollandite formation is more energetically favorable, when Cs was substituted for Ba across the range of Zn-doped compositions investigated in this study. Compositions with high Cs content exhibited lower melting points of approximately 80 °C. In addition, high Cs content materials exhibited a significant reduction in Cs release from the solid to liquid phase by leaching or aqueous corrosion as compared to low Cs content materials. These property changes would be beneficial for applications in radioactive cesium immobilization in a multi-phase ceramic by allowing for decreased processing temperatures and higher cesium weight loadings. More broadly, these results establish the link between composition, structural symmetry, and thermodynamic stability for tunnel structured ceramics with implications in the design of new energy conversion and storage materials.

Similar content being viewed by others

Notes

It is worth noting that for the purposes of this work, hollandite (BaMn8O16) refers to hollandite-type structures which, are generically classified under a mineralogical hollandite supergroup consisting of Mn(IV) and Ti(IV) oxides distinguished by tunneled structures with tetragonal or pseudo-tetragonal crystal symmetry.

Abbreviations

- SYNROC:

-

Synthetic rock

- PCT:

-

Product consistency test

- r A :

-

Average radius of atoms on A-site

- r B :

-

Average radius of atoms on B-site

- r O :

-

Radius of oxygen

- t H :

-

Tolerance factor

- Z B :

-

Valence of B cation

- δ A :

-

Excess size of A cation

- δ B :

-

Excess size of B cation

References

Carter ML, Vance ER, Li H (2004) Hollandite-rich ceramic melts for the immobilisation of Cs. MRS Proc. https://doi.org/10.1557/PROC-807-249

Carter ML, Vance ER (2008) HIPed tailored ceramic waste forms for the immobilisation of Cs, Sr and Tc. MRS Proc. https://doi.org/10.1557/PROC-1107-323

Ringwood AE, Kesson SE, Ware NG et al (1979) Immobilisation of high level nuclear reactor wastes in SYNROC. Nat J 278:219–223

Tang M, Tumurugoti P, Clark B et al (2016) Heavy ion irradiations on synthetic hollandite-type materials: Ba1.0Cs0.3A2.3Ti5.7O16(A = Cr, Fe, Al). J Solid State Chem 239:58–63. https://doi.org/10.1016/j.jssc.2016.04.014

Ringwood AE, Kesson SE, Ware NG et al (1979) The SYNROC process: a geochemical approach to nuclear waste immobilization. Geochem J 13:141–165

Abdelouas A, Utsunomiya S, Suzuki T et al (2008) Effects of ionizing radiation on the hollandite structure-type: Ba0.85Cs0.26Al1.35Fe0.77Ti5.90O16. Am Mineral 93:241–247. https://doi.org/10.2138/am.2008.2563

Cheary RW (1986) An analysis of the structural character of hollandite compounds. Acta Crystallogr Sect B Struct Sci 42:229–236

Gombert D, Piet S, Trickel T et al (2008) Combined waste form cost trade study; INL/EXT-08-14993 (GNEPSYSA- PMO-MI-DV-2009-000003). Idaho National Laboratory, Idaho Falls, ID

Lee WE, Ojovan MI, Stennett MC, Hyatt NC (2006) Immobilisation of radioactive waste in glasses, glass composite materials and ceramics. Adv Appl Ceram 105:3–12. https://doi.org/10.1179/174367606X81669

Chen TY, Maddrell ER, Hyatt NC, Hriljac JA (2016) A potential wasteform for Cs immobilization: synthesis, structure determination, and aqueous durability of Cs2TiNb6O18. Inorg Chem 55:12686–12695. https://doi.org/10.1021/acs.inorgchem.6b01826

Aubin-Chevaldonnet V, Caurant D, Dannoux A et al (2007) Preparation and characterization of (Ba, Cs)(M, Ti)8O16 (M = Al3+, Fe3+, Ga3+, Cr3+, Sc3+, Mg2+) hollandite ceramics developed for radioactive cesium immobilization. J Nucl Mater 366:137–160. https://doi.org/10.1016/j.jnucmat.2006.12.051

Costa GCC, Xu H, Navrotsky A (2013) Thermochemistry of barium hollandites. J Am Ceram Soc 96:1554–1561. https://doi.org/10.1111/jace.12224

Xu Y, Wen Y, Grote R et al (2016) A-site compositional effects in Ga-doped hollandite materials of the form Ba x Cs y Ga 2x + y Ti 8 − 2x − y O 16: implications for Cs immobilization in crystalline ceramic waste forms. Sci Rep. https://doi.org/10.1038/srep27412

Carter ML (2004) Tetragonal to monoclinic phase transformation at room temperature in BaxFe2xTi8-2xO16 hollandite due to increased Ba occupancy. Mater Res Bull 39:1075–1081. https://doi.org/10.1016/j.materresbull.2004.02.018

Xu H, Wu L, Zhu J, Navrotsky A (2015) Synthesis, characterization and thermochemistry of Cs-, Rb- and Sr-substituted barium aluminium titanate hollandites. J Nucl Mater 459:70–76. https://doi.org/10.1016/j.jnucmat.2015.01.014

Zandbergen HW, Everstijn PLA, Mijlhoff FC et al (1987) Composition, constitution and stability of the synthetic hollandites AxM4 − 2xN2xO8, M = Ti, Ge, Ru, Zr, Sn and N = Al, Sc, Cr, Ga, Ru, In and the system (A, Ba)xTiyAlzO8 with A = Rb, Cs, Sr. Mater Res Bull 22:431–438. https://doi.org/10.1016/0025-5408(87)90252-2

Amoroso J, Marra JC, Tang M et al (2014) Melt processed multiphase ceramic waste forms for nuclear waste immobilization. J Nucl Mater 454:12–21. https://doi.org/10.1016/j.jnucmat.2014.07.035

Cheary RW, Squadrito R (1989) A structural analysis of barium magnesium hollandites. Acta Crystallogr Sect B Struct Sci 45:205–212. https://doi.org/10.1107/S0108768188014053

Xu Y, Grote R, Wen Y et al (2016) Development of Ga doped hollandites Ba x Cs y (Ga 2x + y Ti 8 − 2x − y)O 6 for Cs Immobilization. Ceramics for energy conversion, storage, and distribution systems. Wiley, Hoboken, pp 157–164

Brinkman KS, Amoroso J, Marra JC, Tang M (2013) Crystalline ceramic waste forms: comparison of reference process for ceramic waste form fabrication, SRNL-STI-2013-00442

Bystrom A, Bystrom AM (1950) The crystal structure of hollandite, the related manganese oxide minearls, and Alpha-MnO2. ACTA Crystallogr 3:146–154. https://doi.org/10.1107/S0365110X5000032X

Post JE, Von Dreele RB, Buseck PR (1982) Symmetry and cation displacements in hollandites: structure refinements of hollandite, cryptomelane and priderite. Acta Crystallogr Sect B Struct Crystallogr Cryst Chem 38:1056–1065. https://doi.org/10.1107/S0567740882004968

Kesson SE, White TJ (1986) Radius ratio tolerance factors and the stability of hollandites. J Solid State Chem 63:122–125. https://doi.org/10.1016/0022-4596(86)90160-X

Zhang J, Burnham CW (1994) Hollandite-type phases: geometric consideration of unit-cell size and symmetry. Am Mineral 79:168–174

Haaker RF, Ewing RC (1981) Naturally occurring crystalline phases: analogues for radioactive waste forms, PNL-3505

Cai J, Liu J, Willis WS, Suib SL (2001) Framework do** of iron in tunnel structure cryptomelane. Chem Mater. https://doi.org/10.1021/cm0014233

Xu Y, Feygenson M, Page K et al (2016) Structural evolution in hollandite solid solutions across the A-site compositional range from Ba1.33Ga2.66Ti5.34O16 to Cs1.33Ga1.33Ti6.67O16. J Am Ceram Soc 4106:4100–4106. https://doi.org/10.1111/jace.14443

Aubin-Chevaldonnet V, Badot JC, Caurant D (2007) The permittivity and the conductivity of Ba-hollandite Ba1.16M2.32Ti5.68O16 (M = Al, Ga) observed by dielectric spectroscopy. Solid State Ion 178:1274–1281. https://doi.org/10.1016/j.ssi.2007.06.016

Zhang J, Ko J, Hazen R, Prewitt C (1993) High-pressure crystal chemistry of KAlSirOr hollandite. Am Mineral 78:493–499

Carter ML, Jostsons A, Vance ER (2003) Hollandite containing ceramic, Australian Nuclear Science & Technology Organization. Patent Publication Number WO/2003/05864, 07/17/2003, International Application Number PCT/AU2003/000031

Hyatt NC, Stennett MC, Fiddy SG et al (2006) Synthesis and characterisation of transition metal substituted barium hollandite ceramics. MRS Proc 932(60):1. https://doi.org/10.1557/PROC-932-60.1

Remya R, Murali KP, Potty SN, Priyadarshini V (2005) Structure and dielectric properties of Ba1–xSrx ZnTi7O16 hollandite ceramics. J Electron Mater 34:1076–1080

Carter ML, Vance ER, Cassidy DJ et al (2004) Hollandite ceramics: effect of composition on melting temperature. Ceram Trans 168:207–216

Bibler NE, Jantzen CM (1989) The product consistency test and its role in the waste acceptance process for DWPF glass. Manag Radioact Wastes Non-Radioactive Wastes from Nucl Facil 743–749

Hench LL, Clark DE, Campbell J (1984) High level waste immobilization forms. Nucl Chem Waste Manag 5:149–173. https://doi.org/10.1016/0191-815X(84)90045-7

Navrotsky A, Rock PA (2014) Progress and new directions in calorimetry: a 2014 perspective. J Am Ceram Soc 3359:3349–3359. https://doi.org/10.1111/jace.13278

Navrotsky A (1997) Progress and new directions in high temperature calorimetry revisited. Phys Chem Miner 24:222–241

Cheary RW, Squadrito R (1992) Electron and X-ray diffraction from antiphase domains in the barium magnesium hollandite Ba1.33Mg1.33Ti6.67O16. Acta Crystallogr Sect A Found Crystallogr 48:15–27. https://doi.org/10.1107/S0108767391008668

Aubin V, Caurant D, Gourier D et al (2003) Synthesis, characterization and study of the radiation effects on hollandite ceramics developed for cesium immobilization. MRS Proc 807:315–320. https://doi.org/10.1557/PROC-807-315

International Centre for Diffraction Data, Powder Diffraction File, Joint Committee on Powder Diffraction Standards, Philadelphia, PA, 1974–present

Cheary RW, Kwiatkowska J (1984) An X-ray structural analysis of cesium substitution in the barium hollandite phase of synroc. J Nucl Mater 125:236–243

Carter ML, Withers RL (2005) A universally applicable composite modulated structure approach to ordered BaxMyTi8-yO16 hollandite-type solid solutions. J Solid State Chem 178:1903–1914. https://doi.org/10.1016/j.jssc.2005.03.040

Amoroso JW, Marra J, Dandeneau CS et al (2017) Cold crucible induction melter test for crystalline ceramic waste form fabrication: a feasibility assessment. J Nucl Mater 486:283–297. https://doi.org/10.1016/j.jnucmat.2017.01.028

Amoroso J, Marra J, Conradson SD et al (2014) Melt processed single phase hollandite waste forms for nuclear waste immobilization: Ba1.0Cs0.3A2.3Ti5.7O16; A = Cr, Fe, Al. J Alloys Compd 584:590–599. https://doi.org/10.1016/j.jallcom.2013.09.087

Wen Y, Xu Y, Brinkman KS, Shuller-Nickles L (2018) Atomistic scale investigation of cation ordering and phase stability in Cs-substituted Ba1.33Zn1.33Ti6.67O16, Ba1.33Ga2.66Ti5.67O16 and Ba1.33Al2.66Ti5.33O16 hollandite. Sci Rep 8:1–11. https://doi.org/10.1038/s41598-018-22982-7

Acknowledgements

KSB and MZ acknowledge support of thermodynamic measurements as part of the Center for Hierarchical Waste Form Materials, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences under Award No. DE-SC0016574. LSN gratefully acknowledges financial support from the DOE-EPSCoR Project Number: DE-SC0012530, “Radionuclide Waste Disposal: Development of Multi-scale Experimental and Modeling Capabilities” for support of modeling. The calorimetric experiments carried out at University of California, Calorimetry at Davis were supported as part of the Materials Science of Actinides, an Energy Frontier Research Center funded by the U.S. Department of Energy, Office of Science, Basic Energy Sciences under Award Number DE-SC0001089. JA acknowledges the support of durability testing by the U.S. Department of Energy, Office of Nuclear Energy, Fuel Cycle Technology, Materials Recovery and Waste Form Development Campaign. Work conducted at Savannah River National Laboratory was supported by the U.S. Department of Energy under contract number DE-AC09-08SR22470.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

K. Brinkman is a member of the editorial board for Journal of Materials Science. The authors declare that they have no other conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Grote, R., Zhao, M., Shuller-Nickles, L. et al. Compositional control of tunnel features in hollandite-based ceramics: structure and stability of (Ba,Cs)1.33(Zn,Ti)8O16. J Mater Sci 54, 1112–1125 (2019). https://doi.org/10.1007/s10853-018-2904-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2904-1