Abstract

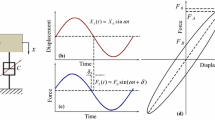

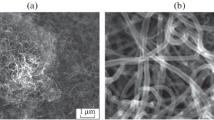

This work studies the effects of loading various functionalized multiwall carbon nanotubes (carboxyl, –COOH-MWCNTs) on the morphological and the field-dependent rheological properties of magnetorheological elastomers (MREs). A new type of MRE, which is reinforced by various loading from 0 to 1.5 wt% of COOH-MWCNT, is fabricated and experimentally investigated. The morphology of COOH-MWCNT and MRE with COOH-MWCNTs is characterized using field emission scanning electron microscopy and transmission electron microscopy. The results indicate that the COOH-MWCNTs are well embedded and dispersed randomly in the MRE structures. The rheological properties under different magnetic fields are evaluated using parallel plate rheometers. The influence of COOH-MWCNT content on the viscoelastic performance of the MRE is systematically investigated. It is found that when a higher content of COOH-MWCNT (up to 1.0 wt%) is added in the MRE, the MRE exhibits a higher MR effect of up to 17.5%. It is also shown that COOH-MWCNT acts as a reinforcing agent that leads to an enhancement in MR performance.

Similar content being viewed by others

Abbreviations

- MR:

-

Magnetorheological

- MRE:

-

Magnetorheological elastomer

- MRF:

-

Magnetorheological fluid

- MRG:

-

Magnetorheological grease

- NR:

-

Natural rubber

- SMR:

-

Standard Malaysia rubber

- CIP:

-

Carbonyl iron particle

- COOH-MWCNT:

-

Carboxyl multiwall carbon nanotubes

- EPO:

-

Epoxidized palm oil

- G′:

-

Storage modulus

- G′0 :

-

Storage modulus (without magnetic field)

- FESEM:

-

Field emission scanning electron microscopy

- TEM:

-

Transmission electron microscopy

- MRD:

-

Magnetorheological device

- ΔG :

-

Magneto-induced modulus

References

Mazlan SA (2008) The behaviour of magnetorheological fluids in squeeze mode. Dublin City University, Dublin

Yunus NA, Mazlan SA, Ubaidillah et al (2016) Rheological properties of isotropic magnetorheological elastomers featuring an epoxidized natural rubber. Smart Mater Struct 25:107001. https://doi.org/10.1088/0964-1726/25/10/107001

Mohamad N, Mazlan SA, Ubaidillah (2016) Effect of carbonyl iron particles composition on the physical characteristics of MR grease. p 40027

Ubaidillah, Imaduddin F, Li YC et al (2016) A new class of magnetorheological elastomers based on waste tire rubber and the characterization of their properties. Smart Mater Struct 25:1–15. https://doi.org/10.1088/0964-1726/25/11/115002

Zhang W, Gong XL, Xuan SH, Xu YG (2010) High-performance hybrid magnetorheological materials: preparation and mechanical properties. Ind Eng Chem Res 49:12471–12476. https://doi.org/10.1021/ie101904f

Li W, Zhang X (2008) Research and applications of MR elastomers. Recent Patents Mech Eng 1:161–166. https://doi.org/10.2174/2212797610801030161

Carlson JD, Jolly MR (2000) MR fluid, foam and elastomer devices. Mechatronics 10:555–569. https://doi.org/10.1016/S0957-4158(99)00064-1

Jolly MR, Carlson JD, Muñoz BC (1996) A model of the behaviour of magnetorheological materials. Smart Mater Struct 5:607–614. https://doi.org/10.1088/0964-1726/5/5/009

Yu M, Fu J, Ju BX et al (2013) Influence of x-ray radiation on the properties of magnetorheological elastomers. Smart Mater Struct 22:125010. https://doi.org/10.1088/0964-1726/22/12/125010

Kavlicoglu BM, Gordaninejad F, Wang X (2013) Study of a magnetorheological grease clutch. Smart Mater Struct 22:125030. https://doi.org/10.1088/0964-1726/22/12/125030

Boczkowska A, Awietjan SF (2009) Urethane magnetorheological elastomers—manufacturing, microstructure and properties. Solid State Phenom 154:107–112. https://doi.org/10.4028/www.scientific.net/SSP.154.107

Chertovich A, Stepanov G, Kramarenko E, Khokhlov A (2010) New composite elastomers with giant magnetic response. Macromol Mater Eng 295:336–341. https://doi.org/10.1002/mame.200900301

Jiang W, Yao J, Gong X, Chen L (2008) Enhancement in magnetorheological effect of magnetorheological elastomers by surface modification of iron particles. Chin J Chem Phys 21:87–92. https://doi.org/10.1088/1674-0068/21/01/87-92

Agirre-Olabide I, Elejabarrieta MJ, Bou-Ali MM (2015) Matrix dependence of the linear viscoelastic region in magnetorheological elastomers. J Intell Mater Syst Struct 26:1880–1886. https://doi.org/10.1177/1045389X15580658

Zhu J, Xu Z, Guo Y (2013) Experimental and modeling study on magnetorheological elastomers with different matrices. J Mater Civ Eng 25:1762–1771. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000727

Khimi SR, Pickering KL (2015) Comparison of dynamic properties of magnetorheological elastomers with existing antivibration rubbers. Compos Part B Eng 83:175–183. https://doi.org/10.1016/j.compositesb.2015.08.033

Pickering KL, Raa Khimi S, Ilanko S (2015) The effect of silane coupling agent on iron sand for use in magnetorheological elastomers part 1: surface chemical modification and characterization. Compos Part A Appl Sci Manuf 68:377–386. https://doi.org/10.1016/j.compositesa.2014.10.005

Sui G, Zhong WH, Yang XP et al (2008) Preparation and properties of natural rubber composites reinforced with pretreated carbon nanotubes. Polym Adv Technol. https://doi.org/10.1002/pat.1163

Damiani R (2014) Interface control and viscoelastic behavior of magnetorheological nanocomposites. University of California, Berkeley

Ge L, Gong X, Fan Y, Xuan S (2013) Preparation and mechanical properties of the magnetorheological elastomer based on natural rubber/rosin glycerin hybrid matrix. Smart Mater Struct 22:115029. https://doi.org/10.1088/0964-1726/22/11/115029

Chen L, Gong X, Jiang W et al (2007) Investigation on magnetorheological elastomers based on natural rubber. J Mater Sci 42:5483–5489. https://doi.org/10.1007/s10853-006-0975-x

Ahmad Khairi MH, Mazlan SA, Ubaidillah et al (2017) The field-dependent complex modulus of magnetorheological elastomers consisting of sucrose acetate isobutyrate ester. J Intell Mater Syst Struct 28:1993–2004. https://doi.org/10.1177/1045389X16682844

Wang Y, Zhang X, Oh J, Chung K (2015) Fabrication and properties of magnetorheological elastomers based on CR/ENR self-crosslinking blends. Smart Mater Struct 24:95006. https://doi.org/10.1088/0964-1726/24/9/095006

Sorokin VV, Ecker E, Stepanov GV et al (2014) Experimental study of the magnetic field enhanced Payne effect in magnetorheological elastomers. Soft Matter 10:8765–8776. https://doi.org/10.1039/C4SM01738B

Wu J, Gong X, Fan Y, **a H (2010) Anisotropic polyurethane magnetorheological elastomer prepared through in situ polycondensation under a magnetic field. Smart Mater Struct 19:105007. https://doi.org/10.1088/0964-1726/19/10/105007

Zhou Y, Jerrams S, Betts A, et al (2013) The effect of microstructure on the dynamic equi- biaxial fatigue behaviour of magnetorheological elastomers. In: 8th European conference on constitutive models for rubbers (ECCMR VIII). pp 25–28

Koo J-H, Dawson A, Jung H-J (2012) Characterization of actuation properties of magnetorheological elastomers with embedded hard magnetic particles. J Intell Mater Syst Struct 23:1049–1054. https://doi.org/10.1177/1045389X12439635

Li GH, Huang XG, Gu XY, Wang J (2013) Fabrication and mechanical properties study of the magnetorheological elastomer. Appl Mech Mater 376:148–152. https://doi.org/10.4028/www.scientific.net/AMM.376.148

Ubaidillah, Sutrisno J, Purwanto A, Mazlan SA (2015) Recent progress on magnetorheological solids: materials, fabrication, testing, and applications. Adv Eng Mater 17:563–597. https://doi.org/10.1002/adem.201400258

Li Y, Li J, Li W, Du H (2014) A state-of-the-art review on magnetorheological elastomer devices. Smart Mater Struct 23:123001. https://doi.org/10.1088/0964-1726/23/12/123001

Aloui S, Klüppel M (2015) Magneto-rheological response of elastomer composites with hybrid-magnetic fillers. Smart Mater Struct 24:25016. https://doi.org/10.1088/0964-1726/24/2/025016

Li Y, Li J, Li W, Samali B (2013) Development and characterization of a magnetorheological elastomer based adaptive seismic isolator. Smart Mater Struct 22:35005. https://doi.org/10.1088/0964-1726/22/3/035005

Chen L, Gong XL, Li WH (2008) Effect of carbon black on the mechanical performances of magnetorheological elastomers. Polym Test 27:340–345. https://doi.org/10.1016/j.polymertesting.2007.12.003

Yu M, Zhu M, Fu J et al (2015) A dimorphic magnetorheological elastomer incorporated with Fe nano-flakes modified carbonyl iron particles: preparation and characterization. Smart Mater Struct 24:115021. https://doi.org/10.1088/0964-1726/24/11/115021

Padalka O, Song HJ, Wereley NM et al (2010) Stiffness and dam** in Fe Co, and Ni nanowire-based magnetorheological elastomeric composites. IEEE Trans Magn 46:2275–2277. https://doi.org/10.1109/TMAG.2010.2044759

Li R, Sun LZ (2014) Dynamic viscoelastic behavior of multiwalled carbon nanotube-reinforced magnetorheological (MR) nanocomposites. J Nanomech Micromech 4:A4013014. https://doi.org/10.1061/(ASCE)NM.2153-5477.0000065

Li R, Sun LZ (2011) Dynamic mechanical behavior of magnetorheological nanocomposites filled with carbon nanotubes. Appl Phys Lett 99:131912. https://doi.org/10.1063/1.3645627

Bica I, Anitas EM, Bunoiu M et al (2014) Hybrid magnetorheological elastomer: influence of magnetic field and compression pressure on its electrical conductivity. J Ind Eng Chem 20:3994–3999. https://doi.org/10.1016/j.jiec.2013.12.102

Landa RA, Soledad Antonel P, Ruiz MM et al (2013) Magnetic and elastic anisotropy in magnetorheological elastomers using nickel-based nanoparticles and nanochains. J Appl Phys 114:213912. https://doi.org/10.1063/1.4839735

Aziz SAA, Mazlan SA, Ismail NIN et al (2016) Effects of multiwall carbon nanotubes on viscoelastic properties of magnetorheological elastomers. Smart Mater Struct 25:77001. https://doi.org/10.1088/0964-1726/25/7/077001

Abdullateef AA, Thomas SP, Al-Harthi MA et al (2012) Natural rubber nanocomposites with functionalized carbon nanotubes: mechanical, dynamic mechanical, and morphology studies. J Appl Polym Sci 125:E76–E84. https://doi.org/10.1002/app.35021

Petriccione A, Zarrelli M, Antonucci V, Giordano M (2014) Aggregates of chemically functionalized multiwalled carbon nanotubes as viscosity reducers. Materials (Basel) 7:3251–3261. https://doi.org/10.3390/ma7043251

Qiu L, Chen Y, Yang Y et al (2013) A study of surface modifications of carbon nanotubes on the properties of polyamide 66/multiwalled carbon nanotube composites. J Nanomater 2013:1–8. https://doi.org/10.1155/2013/252417

Kong I, Ahmad SH, Shanks R (2016) Properties enhancement in multiwalled carbon nanotube-magnetite hybrid-filled polypropylene natural rubber nanocomposites through functionalization and processing methods. Sci Eng Compos Mater 23:257–267. https://doi.org/10.1515/secm-2014-0124

Silva VA, de Folgueras LC, Cândido GM et al (2013) Nanostructured composites based on carbon nanotubes and epoxy resin for use as radar absorbing materials. Mater Res 16:1299–1308. https://doi.org/10.1590/S1516-14392013005000146

Abdul Aziz SA, Mazlan SA, Nik Ismail NI et al (2017) An enhancement of mechanical and rheological properties of magnetorheological elastomer with multiwall carbon nanotubes. J Intell Mater Syst Struct. https://doi.org/10.1177/1045389X17705211

Ondreas F, Jancar J (2015) Temperature, frequency, and small static stress dependence of the molecular mobility in deformed amorphous polymers near their glass transition. Macromolecules 48:4702–4716. https://doi.org/10.1021/acs.macromol.5b00550

Zhang H, Wei Y, Kang Z et al (2017) Influence of partial substitution for CB with MWNTs on performance of CB-filled NR composites. Micro Nano Lett 12:117–122. https://doi.org/10.1049/mnl.2016.0003

Jung HS, Kwon SH, Choi HJ et al (2016) Magnetic carbonyl iron/natural rubber composite elastomer and its magnetorheology. Compos Struct 136:106–112. https://doi.org/10.1016/j.compstruct.2015.10.008

Subramaniam K, Das A, Steinhauser D et al (2011) Effect of ionic liquid on dielectric, mechanical and dynamic mechanical properties of multi-walled carbon nanotubes/polychloroprene rubber composites. Eur Polym J 47:2234–2243. https://doi.org/10.1016/j.eurpolymj.2011.09.021

Michler GH, von Schmeling H-HK-B (2013) The physics and micro-mechanics of nano-voids and nano-particles in polymer combinations. Polymer (Guildf) 54:3131–3144. https://doi.org/10.1016/j.polymer.2013.03.035

Ahmadi M, Shojaei A (2015) Reinforcing mechanisms of carbon nanotubes and high structure carbon black in natural rubber/styrene-butadiene rubber blend prepared by mechanical mixing—effect of bound rubber. Polym Int 64:1627–1638. https://doi.org/10.1002/pi.4964

Hong CH, Kim MW, Zhang WL et al (2016) Fabrication of smart magnetite/reduced graphene oxide composite nanoparticles and their magnetic stimuli-response. J Colloid Interface Sci 481:194–200. https://doi.org/10.1016/j.jcis.2016.07.060

Mordina B, Tiwari RK, Setua DK, Sharma A (2016) Impact of graphene oxide on the magnetorheological behaviour of BaFe12 O19 nanoparticles filled polyacrylamide hydrogel. Polymer (Guildf) 97:258–272. https://doi.org/10.1016/j.polymer.2016.05.026

Ismail H, Ramly AF, Othman N (2011) The effect of carbon black/multiwall carbon nanotube hybrid fillers on the properties of natural rubber nanocomposites. Polym Plast Technol Eng 50:660–666. https://doi.org/10.1080/03602559.2010.551380

Acknowledgements

The author gratefully acknowledges the financial funded by the Ministry of Higher Education, Malaysia PRGS (Vot No: 4L667), Universiti Teknologi Malaysia under GUP Grant (Vot No: 13H55), PDRU Grant (Vot No: 04E02) and also Malaysian Rubber Board for their technical advice and facilities, SHERA Project Prime Award: AID-497-A-16-00004, USAID, as well as Universitas Sebelas Maret (UNS) through Hibah Mandatory 2018.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Aziz, S.A.A., Ubaidillah, Mazlan, S.A. et al. Implementation of functionalized multiwall carbon nanotubes on magnetorheological elastomer. J Mater Sci 53, 10122–10134 (2018). https://doi.org/10.1007/s10853-018-2315-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2315-3