Abstract

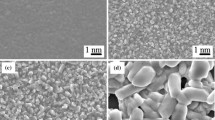

CuInSe2 has become an attractive material for use in the production of thin-film solar cells. Recently, energy conversion efficiencies over 20% have been achieved by CuInSe2 solar cells created using vacuum processes. To reduce manufacturing costs, more recent efforts have focused on non-vacuum processes. In this study, we fabricated solar cells exclusively by wet processes. CuInSe2 absorption layers and In2S3 buffer layers were electrochemically or chemically deposited, and ZnO window layers were formed using solution-based chemical methods. The deposited CuInSe2 absorption layers were heat-treated to improve crystallinity. We deposited a Cd-free buffer layer of In2S3 using a chemical bath method on the CuInSe2 absorption layers, and then ZnO window layers were deposited by a solution-based process. With this system, we successfully fabricated CuInSe2 solar cells and obtained a cell efficiency of 2.38%.

Similar content being viewed by others

References

Chirilă A, Reinhard P, Pianezzi F, Bloesch P, Uhl AR, Fella C, Kranz L, Keller D, Gretener C, Hagendorfer H (2013) Potassium-induced surface modification of Cu(In, Ga)Se2 thin films for high-efficiency solar cells. Nat Mater 12:1107–1111

Philip J, Dimitrios H, Erwin L, Stefan P, Roland W, Richard M, Wiltraud W, Michael P (2011) New world record efficiency for Cu(In, Ga)Se2 thin-film solar cells beyond 20%. Prog Photovolt Res Appl 19:894–897

Kaelin M, Rudmann D, Kurdesau F, Zogg H, Meyer T, Tiwari AN (2005) Low-cost CIGS solar cells by paste coating and selenization. Thin Solid Films 480:486–490

Lincot D, Guillemoles J, Taunier S, Guimard D, Sicx-Kurdi J, Chaumont A, Roussel O, Ramdani O, Hubert C, Fauvarque J (2004) Chalcopyrite thin film solar cells by electrodeposition. Sol Energy 77:725–737

Bhattacharya R, Batchelor W, Wiesner H, Hasoon F, Granata J, Ramanathan K, Alleman J, Keane J, Mason A, Matson R (1998) 14.1% CuIn1−xGaxSe2-based photovoltaic cells from electrodeposited precursors. J Electrochem Soc 145:3435–3440

Yoon H, Park K, Park J, Kim K, Lee J, Kim Y, Lee D (2015) Compensation for cracks formed on an electrochemically deposited CuInSe2 absorption layer. J Electron Mater 44:4779–4786

Lee H, Yoon H, Ji C, Lee D, Lee J, Yun J, Kim Y (2012) Fabrication of CIGS films by electrodeposition method for photovoltaic cells. J Electron Mater 41:3375–3381

Choi C, Lee H, Cha H, Gwak J, Yun JH, Kim J, Kim Y, Lee D (2011) Fabrication of CuIn(Ga)Se2 thin films by electrochemical deposition with additive. J Electrochem Soc 159:E1–E4

Erfurth F, Jehl Z, Bouttemy M, Dahan N, Tran-Van P, Gerard I, Etcheberry A, Greffet J, Powalla M, Voorwinden G (2012) Mo/CuIn(Ga)Se2 back interface chemical and optical properties for ultrathin CIGSe solar cells. Appl Surf Sci 258:3058–3061

Pethe SA, Takahashi E, Kaul A, Dhere NG (2012) Effect of sputtering process parameters on film properties of molybdenum back contact. Sol Energy Mater Sol Cells 100:1–5

Fernandez A, Bhattacharya R (2005) Electrodeposition of CuIn1−xGaxSe2 precursor films: optimization of film composition and morphology. Thin Solid Films 474:10–13

Hibberd C, Chassaing E, Liu W, Mitzi D, Lincot D, Tiwari A (2010) Non-vacuum methods for formation of Cu(In, Ga)(Se, S)(2) thin film photovoltaic absorbers. Prog Photovolt Res Appl 18(6):434–452

Saji V, Choi I, Lee C (2011) Progress in electrodeposited absorber layer for CuIn(1−x)GaxSe2 (CIGS) solar cells. Sol Energy 85(11):2666–2678

Oda Y, Minemoto T, Takakura H (2008) Electrodeposition of crack-free CuGaSe2 thin films from single bath. J Electrochem Soc 155:H292–H295

Song K, Kim K, Han S, Lee H (2004) Effect of Additives on hydrogen evolution and absorption during Zn electrodeposition investigated by EQCM. Electrochem Solid State Lett 7:C20–C24

Oniciu L, Mureşan L (1991) Some fundamental aspects of levelling and brightening in metal electrodeposition. J Appl Electrochem 21:565–574

Bonou L, Eyraud M, Denoyel R, Massiani Y (2002) Influence of additives on Cu electrodeposition mechanisms in acid solution: direct current study supported by non-electrochemical measurements. Electrochim Acta 47:4139–4148

Sebastian P, Calixto M, Bhattacharya RN, Noufi R (1999) CIS and CIGS based photovoltaic structures developed from electrodeposited precursors. Sol Energy Mater Sol Cells 59:125–135

Gopinath G, Miles R, Reddy KR (2013) Influence of bath temperature on the properties of In2S3 films grown by chemical bath deposition. Energy Procedia 34:399–406

Kilani M, Guasch C, Castagné M, Kamoun-Turki N (2012) Structural, optical, and electrical properties of In2S3: Sn thin films grown by chemical bath deposition on Pyrex. J Mater Sci 47:3198–3203

Christian GD, Buffle J, Haerdi W (1980) Study of selenium (IV) at a drop** mercury electrode by cyclic voltammetry with triangle polarization. J Electroanal Chem Interfacial Electrochem 109:187–194

Lee H, Lee W, Kim JY, Ko MJ, Kim K, Seo K, Lee D-K, Kim H (2013) Highly dense and crystalline CuInSe2 thin films prepared by single bath electrochemical deposition. Electrochim Acta 87:450–456

**a D, Li J, Xu M, Zhao X (2008) Electrodeposited and selenized CIGS thin films for solar cells. J Non Cryst Solids 354:1447–1450

Hsiao K, Liu J, Hsieh H, Jiang T (2013) Electrical impact of MoSe2 on CIGS thin-film solar cells. Phys Chem Chem Phys 15(41):18174–18178

Yoon SJ, Lim I, Kang SH, Lee JK, Lee HY, Lee W, Han S (2012) Structural and optical properties of chemically deposited CuInSe2 thin film in acidic medium. J Nanosci Nanotechnol 12:4313–4316

Pankove JI (1971) Optical processes in semiconductors, 2nd edn. Dover Book, New York

Valderrama R, Sebastian P, Enriquez JP, Gamboa S (2005) Photoelectrochemical characterization of CIGS thin films for hydrogen production. Sol Energy Mater Sol Cells 88:145–155

Asenjo B, Chaparro A, Gutiérrez M, Herrero J, Maffiotte C (2004) Quartz crystal microbalance study of the growth of indium(III) sulphide films from a chemical solution. Electrochim Acta 49:737–744

Mari B, Mollar M, Soro D, Henriquez R, Schrebler R, Gomez H (2013) Electrodeposition of In2S3 thin films onto FTO substrate from DMSO solution. Int J Electrochem Sci 8:3510–3523

Mesa F, Chamorro W, Hurtado M (2015) Optical and structural study of In2S3 thin films growth by co-evaporation and chemical bath deposition (CBD) on Cu3BiS3. Appl Surf Sci 350:38–42

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Park, K., Park, J., Park, S. et al. Fabrication of Cd-free CuInSe2 solar cells using wet processes. J Mater Sci 52, 13533–13540 (2017). https://doi.org/10.1007/s10853-017-1452-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1452-4