Abstract

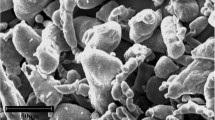

Wear tests were conducted on an aluminum Al-1050 alloy after processing by equal-channel angular pressing (ECAP). The results show that the coefficient of friction remains unchanged after processing by ECAP, but there is a decrease in the wear resistance and a mass loss that increases with increasing numbers of ECAP passes. The results are consistent with a wear mechanism map and confirm the occurrence of a severe wear mechanism. The decreasing wear resistance after ECAP is attributed to the significant grain refinement introduced by ECAP and the lack of a strain hardening capability.

Similar content being viewed by others

References

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT (2006) JOM 58(4):33

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Zhilyaev AP, Langdon TG (2008) Prog Mater Sci 53:893

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Scripta Mater 39:1221

Tsuji N, Saito Y, Utsunomiya H, Tanigawa S (1999) Scripta Mater 40:795

Horita Z, Fu**ami T, Nemoto M, Langdon TG (2000) Metall Mater Trans 31A:691

Höppel HW, Kautz M, Xu C, Murashkin M, Langdon TG, Valiev RZ, Mughrabi H (2006) Int J Fatigue 28:1001

Horita Z, Furukawa M, Nemoto M, Barnes AJ, Langdon TG (2000) Acta Mater 48:3633

Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Acta Mater 46:3317

Kawasaki M, Horita Z, Langdon TG (2009) Mater Sci Eng A524:143

Valiev RZ, Krasilnikov NA, Tsenev NK (1991) Mater Sci Eng A137:35

Valiev RZ, Alexandrov IV, Zhu YT, Lowe TC (2002) J Mater Res 17:5

Kim WJ, Sa YK (2006) Scripta Mater 54:1391

Estrin Y, Janecek M, Raab GI, Valiev RZ, Zi A (2007) Metall Mater Trans 38A:1906

Qiao XG, Gao N, Moktadir Z, Kraft M, Starink MJ (2010) J Micromech Microeng 20:045029

Latysh V, Krallics G, Alexandrov I, Fodor A (2006) Curr Appl Phys 6:262

Valiev RZ, Semenova IP, Latysh VV, Rack H, Lowe TC, Petruzelka J, Dluhos L, Hrusak D, Sochova J (2008) Adv Eng Mater 10:B15

Sato H, Elhadad S, Sitdikov O, Watanabe Y (2008) Mater Sci Forum 584–586:971

Abd El Aal MI, El Mahallawy N, Shehata FA, Abd El Hameed M, Yoon EY, Kim HS (2010) Mater Sci Eng A527:3726

Kucukomeroglu T (2010) Mater Des 31:782

Kim YS, Yu HS, Shin DH (2009) Int J Mater Res 100:871

Kim YS, Ha JS, Kim WJ (2004) Mater Sci Forum 449–452:597

Gao LL, Cheng XH (2007) Tribol Lett 27:221

Gao LL, Cheng XH (2008) Wear 265:986

Gao LL, Cheng XH (2008) Mater Sci Eng A473:259

Korshunov LG, Noskova NI, Korznikov AV, Chernenko NL, Vil’danova NF (2009) Phys Met Metallogr 108:519

Wang ZB, Tao NR, Li S, Wang W, Liu G, Lu J, Lu K (2003) Mater Sci Eng A352:144

Stolyarov VV, Shuster LS, Migranov MS, Valiev RZ, Zhu YT (2004) Mater Sci Eng A371:313

La P, Ma J, Zhu YT, Yang J, Liu W, Xue Q, Valiev RZ (2005) Acta Mater 53:5167

Garbacz H, Gradzka-Dahlke M, Kurzydlowski KJ (2007) Wear 263:572

Purcek G, Saray O, Kul O, Karaman I, Yapici GG, Haouaoui M, Maier HJ (2009) Mater Sci Eng A517:97

Cheng X, Li Z, **ang G (2007) Mater Des 28:2218

Purcek G, Saray O, Kucukomeroglu T, Haouaoui M, Karaman I (2010) Mater Sci Eng A527:3480

Furukawa M, Horita Z, Nemoto M, Langdon TG (2001) J Mater Sci 36:2835. doi:10.1023/A:1017932417043

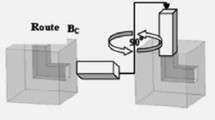

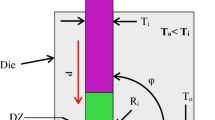

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Scripta Mater 35:143

Furukawa M, Iwahashi Y, Horita Z, Nemoto M, Langdon TG (1998) Mater Sci Eng A257:328

Oh-ishi K, Horita Z, Furukawa M, Nemoto M, Langdon TG (1998) Metall Mater Trans 29A:2011

Nakashima K, Horita Z, Nemoto M, Langdon TG (1998) Acta Mater 46:1589

Terhune SD, Swisher DL, Oh-ishi K, Horita Z, Langdon TG, McNelley TR (2002) Metall Mater Trans 33A:2173

Salem AA, Langdon TG, McNelley TR, Kalidindi SR, Semiatin SL (2006) Metall Mater Trans 37A:2879

Horita Z, Fu**ami T, Nemoto M, Langdon TG (2001) J Mater Process Technol 117:288

Archard JF (1953) J Appl Phys 24:981

Kuo SM, Rigney DA (1992) Mater Sci Eng A157:131

Rigney DA (2000) Wear 245:1

Zhang J, Alpas AT (1997) Acta Mater 45:513

Pramila BN, Biswas SK (1991) Acta Metall Mater 39:833

Li XY, Tandon KN (2000) Wear 245:148

Tandon KN, Li XY (1997) Scripta Mater 38:7

Lim SC, Ashby MF (1987) Acta Metall 35:1

Lim SC, Ashby MF, Brunton JH (1987) Acta Metall 35:1343

Liu Y, Asthana R, Rohatgi P (1991) J Mater Sci 26:99. doi:10.1007/BF00576038

Hiratsuka K, Muramoto K (2005) Wear 259:467

Rigney DA (1994) Wear 175:63

Blau PJ (1981) Wear 71:29

Kim HJ, Karthikeyan S, Rigney D (2007) Wear 263:849

Cetlin PR, Aguilar MTP, Figueiredo RB, Langdon TG (2010) J Mater Sci 45:4561. doi:10.1007/s10853-010-4384-9

Wang J, Horita Z, Furukawa M, Nemoto M, Tsenev NK, Valiev RZ, Ma Y, Langdon TG (1993) J Mater Res 8:2810

Horita Z, Smith DJ, Nemoto M, Valiev RZ, Langdon TG (1998) J Mater Res 13:446

Acknowledgements

This work was supported by a studentship from the School of Engineering Sciences at the University of Southampton together with a scholarship from the China Scholarship Council (CTW). Partial support was provided by EPSRC under Grant No EP/D00313X/1 and by the National Science Foundation of the United States under Grant No. DMR-0855009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, C.T., Gao, N., Wood, R.J.K. et al. Wear behavior of an aluminum alloy processed by equal-channel angular pressing. J Mater Sci 46, 123–130 (2011). https://doi.org/10.1007/s10853-010-4862-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4862-0