Abstract

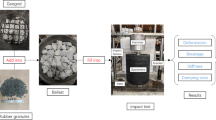

Tire derived aggregates (TDA) has been used successfully in numerous civil engineering projects. However, considerably few researchers investigated its performance in dynamic applications, despite the high energy absorption ability of TDA. Moreover, testing TDA samples with larger aggregate size is troublesome due to the limitation in specimen sizes available in geotechnical laboratories. Therefore, this paper provides more insights on the dynamic behavior of TDA with larger aggregate sizes. This work also investigates the extent of specimen size effect on the dynamic properties of TDA and Granulated rubber (GR). A series of undrained strain-controlled cyclic triaxial tests were performed using three specimen sizes with diameters of 70, 101 and 152 mm. TDA samples had maximum aggregate size of 19.1 and 25.4 mm, however, the GR samples had only a maximum aggregate size of 4.75 mm. All tests were performed at consolidation stress range of 25 to 100 kPa and shear strain range of 0.1 to 10%. It was found that the 70 mm specimens overestimated the shear modulus of TDA samples by a maximum of 15 to 26%. However, no significant variation was found in the shear modulus that is mobilized by the 101 and 152 mm specimens. Also, GR samples were marginally influenced by specimen size. Furthermore, regardless of the aggregate size, the dam** capacity is independent of specimen size. Lastly, it is recommended to use triaxial specimen size with a diameter four times larger than the maximum aggregate size of considered TDA material.

Similar content being viewed by others

Data availability

All of the generated data is being presented in the manuscript.

References

Ahn I-S, Cheng L (2017) Seismic analysis of semi-gravity RC cantilever retaining wall with TDA backfill. Front Struct Civ Eng 11(4):455–469

Amanta AS, Dasaka SM (2022) Dynamic characteristics and liquefaction behavior of sand–tire chip mixes. J Mater Civil Eng 34(10)

Anastasiadis A, Senetakis K, Pitilakis K (2012) Small-strain shear modulus and dam** ratio of sand–rubber and gravel–rubber mixtures. Geotech Geol Eng 30(2):363–382

ASTM D3999 (2011) D3999/D3999M standard test methods for the determination of the modulus and dam** properties of soils using the cyclic triaxial apparatus

Bahadori H, Farzalizadeh R (2018) Dynamic properties of saturated sands mixed with tyre powders and tyre shreds. Int J Civil Eng 16(4):395–408

Boominathan A (2023) Innovative geotechnical solutions for base isolation of buildings. Indian Geotech J 54:3–39

Dhanya JS, Boominathan A, Banerjee S (2019) Performance of geo-base isolation system with geogridreinforcement. Int J Geomech 19:1–13. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001469

El Naggar H, Iranikhah A (2021) Evaluation of the shear strength behavior of TDA mixed with fine and coarse aggregates for backfilling around buried structures. Sustainability 13(9):5087

El Naggar H, Ashari M, Mahgoub A (2022) Development of an empirical hyperbolic material model for TDA utilizing large-scale triaxial testing. Int J Geotech Eng 16(2):133–142

Fathali M, Esmaeili M, Moghadas Nejad F (2019) Influence of tire-derived aggregates mixed with ballast on ground-borne vibrations. J Modern Transp 27(4):355–363

Feng ZY, Sutter KG (2000) Dynamic properties of granulated rubber/sand mixtures. Geotech Test J 23(3):338–344

Hataf N, Rahimi MM (2006) Experimental investigation of bearing capacity of sand reinforced with randomly distributed tire shreds. Constr Build Mater 20(10):910–916. https://doi.org/10.1016/j.conbuildmat.2005.06.019

Hazarika H, Yasuhara K, Kikuchi Y, Karmokar AK, Mitarai Y (2010) Multifaceted potentials of tire-derived three dimesional geosynthetics in geotechnical applications and their evaluation. Geotext Geomembr 28(3):303–315

Humphrey DN, Sandford TC, Cribbs MM, Manion WP (1993) Shear strength and compressibility of tire chips for use as retaining wall backfill. Transp Res Record Issue (1422):29–35

Karaman M, Demirci HE, Ecemis N, Bhattacharya S (2022) Usage of tyre derived aggregates as backfill around buried pipelines crossing strike-slip faults; model tests. Bull Earthq Eng 20(7):3143–3165

Kazemzadeh M, Moghadam MJ, Zad A (2023) Influence of tire-shred aspect ratio on performance of mechanically stabilized retaining walls. Arab J Sci Eng. https://doi.org/10.1007/s13369-023-08184-y

Kowalska M (2016) Compactness of scrap tyre rubber aggregates in standard proctor test. Proc Eng 161:975–979

Lee JH, Salgado R, Lovell CW, Bernal A (1999) Shredded tires and rubber–sand as lightweight backfill. J Geotech Geoenviron Eng 125(2):132–141

Madhusudhan BR, Boominathan A, Banerjee S (2017) Static and large-strain dynamic properties of sand–rubber tire shred mixtures. J Mater Civ Eng 29(10):4017165

Madhusudhan BR, Boominathan A, Banerjee S (2020) Cyclic simple shear response of sand–rubber tire chip mixtures. Int J Geomech 20(9):4020136

Mahgoub A, El Naggar H (2019) Using TDA as an engineered stress-reduction fill over preexisting buried pipes. J Pipeline Syst 10(1):4018034

Mahgoub A, El Naggar H (2020a) Coupled TDA–geocell stress-bridging system for buried corrugated metal pipes. J Geotech Geoenviron Eng 146(7):4020052

Mahgoub A, El Naggar H (2020b) Innovative application of tire-derived aggregate around corrugated steel plate culverts. J Pipeline Syst 11(3):4020025

Mahgoub A, El Naggar H (2020c) Shallow foundations on lightweight TDA backfill: field tests and 3D numerical modelling. Comput Geotech 126:103761

Mahgoub A, El Naggar H (2022) Using TDA underneath shallow foundations: simplified design procedure. Int J Geotech Eng 16(7):787–801

McCartney JS, Ghaaowd I, Fox PJ, Sanders MJ, Thielmann SS, Sander AC (2017) Shearing behavior of tire-derived aggregate with large particle size. II: cyclic simple shear. J Geotech Geoenviron Eng 143(10):4017079

Moussa A, El Naggar H (2020) Numerical evaluation of buried wave barriers performance. Int J Geosynth Ground Eng 6(4):1–13

Moussa A, El Naggar H (2021) Dynamic characterization of tire derived aggregates. J Mater Civil Eng 33(2):04020471

Moussa A, El Naggar H, Sadrekarimi A (2023) Dynamic characterization of tire derived aggregates using cyclic simple shear and bender element tests. Soil Dyn Earthq Eng 165:107700

Ni P, Qin X, Yi Y (2018) Use of tire-derived aggregate for seismic mitigation of buried pipelines under strike-slip faults. Soil Dyn Earthq Eng 1984 115:495–506

Rios S, Kowalska M, Viana da Fonseca A (2021) Cyclic and dynamic behavior of sand–rubber and clay–rubber mixtures. Geotech Geol Eng 39(5):3449–3467

Rizvi SMF, Wang K, Jalal FE, Tu Y (2022) Evaluation of open and filled (TDA and RSM) trenches efficacy on vibration screening caused by transient loads. Transp Geotech 35:100770

Sarajpoor S, Kavand A, Zogh P, Ghalandarzadeh A (2020) Dynamic behavior of sand–rubber mixtures based on hollow cylinder tests. Constr Build Mater 251:118948

Senetakis K, Anastasiadis A, Pitilakis K (2012a) Dynamic properties of dry sand/rubber (SRM) and gravel/rubber (GRM) mixtures in a wide range of shearing strain amplitudes. Soil Dyn Earthq Eng (1984) 33(1):38–53

Senetakis K, Anastasiadis A, Pitilakis K, Souli A (2012b) Dynamic behavior of sand/rubber mixtures, part II: effect of rubber content on G/G. J ASTM Int 9(2):1–12

Acknowledgements

The authors acknowledge the funding provided by the Natural Sciences and Engineering Research Council of Canada (NSERC) and Divert NS for this research project. Also, the generosity of Halifax C&D is very much appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Moussa, A., El Naggar, H. Effect of Specimen Size on the Dynamic Behavior of Tire-Derived Aggregates (TDA). Geotech Geol Eng 42, 4115–4128 (2024). https://doi.org/10.1007/s10706-024-02775-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-024-02775-8