Abstract

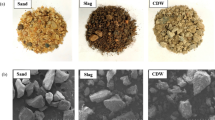

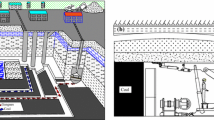

Large-size lump (e.g., coal reject or waste rocks) is one of the most popular backfill materials for underground mines attributed to its cost-effective and easy-to-obtain. The massive void between lumps, however, does generally affect the overall performance in eliminating the ground subsidence. This paper presents a conceptual backfill material, termed as lump-grout (LG) material, the attractive feature of which is that the voids between lumps are totally filled up with high-water content cementitious grout (CG) material. To explore the mechanical behaviour of LG material, a total of 36 LG specimens were prepared and tested under the uniaxial compression and the tensile loading. Other 20 CG specimens were tested in parallel for comparison. Key configurations investigated in the present research covered the particle size of lumps and the water-to-powder ratio of CG material. Test results indicated that the stress–strain behaviour of LG specimen is predominately affected by the strength of CG material. The failure of LG material generally occurred along the interface between lumps and the cementitious grout material rather than the lumps themselves. Compared to CG material, the axial deformation ability of LG material is slightly superior, when the utilization of CG material is significantly reduced. In addition to the backfill material, the proposed LG material can be also used as the infill material for the artificial standing supports for underground spaces.

Similar content being viewed by others

Data Availability

Enquiries about data availability should be directed to the authors.

References

ASTM-C496/C496M-11 (2011) Standard test method for splitting tensile strength of cylindrical concrete specimens. American Society for Testing and Materials, West Conshohocken

ASTM-C136/C136M (2014) Standard test method for sieve analysis of fine and coarse aggregates. American Society for Testing and Materials, West Conshohocken, PA

ASTM-D7012-10 (2010) Standard test Method for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. American Society for Testing and Materials, West Conshohocken

Deng X, Zhang J, de Wit BW et al (2016) Pressure propagation characteristics of solid waste backfilling material during compaction and its applications in situ. Geotech Geol Eng 34:1631–1642

Deng X, Klein B, Tong L, de Wit B (2018) Experimental study on the rheological behavior of ultra-fine cemented backfill. Constr Build Mater 158:985–994

Fang K, Fall M (2020) Shear behavior of the interface between rock and cemented backfill: effect of curing stress, drainage condition and backfilling rate. Rock Mech Rock Eng 53(1):325–336

Huang P, Spearing AJS, Feng J, Jessu KV, Guo S (2018) Effects of solid backfilling on overburden strata movement in shallow depth longwall coal mines in West China. J Geophys Eng 15(5):2194–2208

Li M, Zhang J, Gao R (2016) Compression characteristics of solid wastes as backfill materials. Adv Mater Sci Eng. https://doi.org/10.1155/2016/2496194

Li B, Lan J, Si G et al (2020) NMR-based damage characterisation of backfill material in host rock under dynamic loading. Int J Min Sci Technol 30(3):329–335

Liu L, Fang Z, Qi C et al (2018) Experimental investigation on the relationship between pore characteristics and unconfined compressive strength of cemented paste backfill. Constr Build Mater 179:254–264

Minova (2017) Safety data sheet of CMT Grout. In: M. Australia (Ed.) Sydney

T216 NSW (2012) Sandstone crushing value. NSW Transport Department

Tan L, Ren T, Yang X (2019) The development of a novel backfilling technology: concept and behaviour

Tang R, Zhao B, Li C et al (2023) Experimental study on the effect of fly ash with ammonium salt content on the properties of cemented paste backfill. Constr Build Mater 369:130513

Wang W, Zhang C (2017) Separating coal and gangue using three-dimensional laser scanning. Int J Miner Process 169:79–84

Wang J, Feng P, Hao T et al (2017) Axial compressive behavior of seawater coral aggregate concrete-filled FRP tubes. Constr Build Mater 147:272–285

Wang Y, Wang Z, Wu A et al (2023) Experimental research and numerical simulation of the multi-field performance of cemented paste backfill: review and future perspectives. Int J Miner Metall Mater 30(2):193–208

Xue G, Yilmaz E, Wang Y (2023) Progress and prospects of mining with backfill in metal mines in China. Int J Miner Metall Mater 30:1–19

Yilmaz E, Belem T, Benzaazoua M (2014) Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng Geol 168:23–37

Yin S, Yan Z, Chen X et al (2023) Active roof-contact: the future development of cemented paste backfill. Constr Build Mater 370:130657

Zhang J, Zhang Q, Sun Q et al (2015) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci 74:1439–1448

Zhang Q, Zhang J, Han X et al (2016) Theoretical research on mass ratio in solid backfill coal mining. Environ Earth Sci 75:1–11

Zhang JX, Deng XJ, Zhao X et al (2017) Effective control and performance measurement of solid waste backfill in coal mining. Int J Min Reclam Environ 31(2):91–104

Zhang Q, Zhang J, Wu Z et al (2019) Overview of solid backfilling technology based on coal-waste underground separation in China. Sustainability 11(7):2118

Zhao H (2019) State-of-the-art of standing supports for gob-side entry retaining technology in China. J South Afr Inst Min Metall 119(11):891–906

Zhao H, Ren T, Remennikov A (2021a) Behaviour of FRP-confined coal rejects based backfill material under compression. Constr Build Mater 268:121171

Zhao H, Ren T, Remennikov A (2021b) Behaviour of FRP-confined coal reject concrete columns under axial compression. Compos Struct 262:113621

Zhu X, Guo G, Zha J, Chen T, Fang Q, Yang X (2016) Surface dynamic subsidence prediction model of solid backfill mining. Environ Earth Sci 75(12):1–9

Zuo J, Hong Z, **ong Z et al (2018) Influence of different W/C on the performances and hydration progress of dual liquid high water backfilling material. Constr Build Mater 190:910–917

Acknowledgements

This research is financially supported by the National Natural Science Foundation of China (Nos. 51904268 and 52164011) and the Natural Science Foundation of **njiang Uygur Autonomous Region of China (Nos. 2022D01C411 and 2022D01C039). The first author would like to express his thanks to the University of Wollongong and Minova Australia for their kind supports in PhD research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, H., Ren, T., Remennikov, A. et al. Mechanical Behaviour of Lump-Grout Backfill Material for Underground Spaces. Geotech Geol Eng 41, 4807–4819 (2023). https://doi.org/10.1007/s10706-023-02549-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-023-02549-8