Abstract

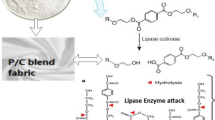

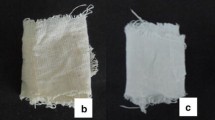

A sustainable approach in all industrial processes is prerequisite in industrial revolution 5 and 6. The need for optimization of all industrial products with less greenhouse gas emissions is beneficial for a better-quality product too. Bio scouring is a sustainable alternative to traditional scouring methods for cellulosic (cotton) fabrics. This research aimed to identify optimal parameters for employing triacylglycerol acylhydrolase (EC 3.1.1.3 Lipase) from Bacillus toyonensis and Bacillus thuringiensis consortium sourced from indigenous hot springs. To optimize the process time, temperature, and pH, the RSM was applied. The experimental ranges for temperature, reaction time, and pH were 6–8, 60–80 °C, and 50–150 min, respectively. The focus of the study was directed towards seven outcomes: Tensile strength warp and weft, tear strength warp and weft, wettability, whiteness index, and weight loss. Through a systematic experimental approach, the study determined the optimal parameter settings for the independent variables, setting the temperature at 70 °C, reaction time at 50 min, and pH at 8. The accuracy of the combination of variables was confirmed by subsequent validation experiments, which produced significant results. This validated the efficacy of the enzyme-assisted bio-scouring approach in enhancing cotton fabric properties while adhering to environmentally friendly practices with comparatively less GHG emissions.

Similar content being viewed by others

Data availability

The original raw data is accessible from the authors as well as from the institutions, and it can be requested at any point for additional assistance or reference.

References

AATCC Technical Manual (1980) AATCC: test method. 39–1980, vol 55, p 286

Anupam K, Swaroop V, Lal PS (2018) Antagonistic, synergistic and interaction effects of process parameters during oxygen delignification of Melia dubia kraft pulp. J Clean Prod 199:420–430

Bashir T, Majeed H, Iftikhar T (2024) Isolation and screening of thermophilic bacteria and its subsequent evaluation for lipases production. Pak J Bot. https://doi.org/10.30848/PJB2024-2(3)

Box GE (1951) P and Wilson KB On the experimental attainment of optimum conditions. J Roy Stat Soc 13:1–45

Calafell M, Garriga P (2004) Effect of some process parameters in the enzymatic scouring of cotton using an acid pectinase. Enzyme Microb Technol 34(3–4):326–331

Candioti LV, De Zan MM, Cámara MS, Goicoechea HC (2014) Experimental design and multiple response optimization. Using the desirability function in analytical methods development. Talanta 124:123–138

Ferreira SC, Bruns RE, Ferreira HS, Matos GD, David JM, Brandão GC, da Silva EP, Portugal LA, Dos Reis PS, Souza AS, Dos Santos WNL (2007) Box-Behnken design: An alternative for the optimization of analytical methods. Anal Chim Acta 597(2):179–186

Hardin IR (2010) Enzymatic treatment versus conventional chemical processing of cotton. Advances in textile biotechnology. Woodhead Publishing, Cambridge, pp 132–149

Holkar CR, Jadhav AJ, Pinjari DV, Mahamuni NM, Pandit AB (2016) A critical review of textile wastewater treatments: possible approaches. J Environ Manag 182:351–366

Lenting HBM, Warmoeskerken MMCG (2004) A fast, continuous enzyme-based pretreatment process concept for cotton containing textiles. Biocatal Biotransform 22(5–6):361–368

Lin CH, Hsieh YL (2001) Direct scouring of greige cotton fabrics with proteases. Text Res J 71(5):425–434

Majeed H, Bhatti HN, Bhatti IA (2019) Replacement of sodium alginate polymer, urea, and sodium bicarbonate in the conventional reactive printing of cellulosic cotton. J Polym Eng 39(7):661–670. https://doi.org/10.1515/polyeng-2019-0076

Majeed H, Iftikhar T, Ahmad K, Qureshi K, Tabinda Altaf F, Iqbal A, Ahmad S, Khalid A (2023) Bulk industrial production of sustainable cellulosic printing fabric using agricultural waste to reduce the impact of climate change. Int J Biol Macromol 253(3):126885. https://doi.org/10.1016/j.ijbiomac.2023.126885

Perincek S, Duran K (2016) Optimization of enzymatic and ultrasonic bio-scouring of linen fabrics by aid of Box–Behnken experimental design. J Clean Prod 135:1179–1188

Raafi SM, Arju SN, Asaduzzaman M, Khan HH, Rokonuzzaman M (2023) Eco-friendly scouring of cotton knit fabrics with enzyme and soapnut: an alternative to conventional NaOH and synthetic surfactant-based scouring. Heliyon. 9:e15236

Rehman A, Raza ZA, Masood R, Hussain MT, Ahmad N (2015) Multi-response optimization in enzymatic desizing of cotton fabric under various chemo-physical conditions using a Taguchi approach. Cellulose 22:2107–2116

Sangwatanaroj U, Choonukulpong K, Ueda M (2003) Cotton scouring with pectinase and lipase/protease/cellulase. AATCC Reviews 3:17–20

Shahid M, Mohammad F, Chen G, Tang RC, **ng T (2016) Enzymatic processing of natural fibres: white biotechnology for sustainable development. Green Chem 18(8):2256–2281

Shanthi R, Krishnabai G (2013) Process optimization for bioscouring of cotton and lycra cotton weft knits by Box and Behnken design. Carbohyd Polym 96(1):291–295

Traore KM, Buschle-Diller G (2000) Textile chemist and colorist & American dyestuff reporter. American Association of Textile Chemists and Colorists, USA

Wang Q, Fan XR, Hua ZZ, Chen J (2007) Optimizing bioscouring condition of cotton knitted fabrics with an alkaline pectinase from Bacillus subtilis WSHB04-02 by using response surface methodology. Biochem Eng J 34(2):107–113

Zhu B, Liu J, Gao W (2017) Effects of snailase treatment on wettability of raw cotton yarns in pre-wetting process of foam sizing. Appl Biochem Biotechnol 182:1065–1075

Funding

The research was funded by the Department of Botany and ORIC, Government College University, Lahore, Pakistan.

Author information

Authors and Affiliations

Contributions

TB; Student, researcher trials, RSM software and applications, TI; Main supervisor, RSM designing, Methodology, total research plan, RSM, results interpretations, HM; Co supervisor, bio scouring process, production, bulk industrial textile trials, fabric testing, paper write up, results interpretations.

Corresponding authors

Ethics declarations

Conflict of interest

There was no conflict of interest acknowledged by the authors.

Ethical approval

This research does not involve any human or animal trials. The other ethics were reviewed and approved by the departmental research approval committee.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bashir, T., Iftikhar, T. & Majeed, H. Bulk industrial textile production of bio scouring for cellulosic fabric utilizing indigenous hot springs triacylglycerol acylhydrolases from Bacillus toyonensis and Bacillus thuringiensis. Cellulose 31, 1353–1381 (2024). https://doi.org/10.1007/s10570-023-05666-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-023-05666-y