Abstract

The development of plant adhesive with good bonding strength, water resistance and thermal stability remains challenging to replace formaldehyde-based adhesive resins that usually release toxic formaldehyde. Herein, an environmentally friendly bioadhesive derived from cottonseed meal waste and cellulose sawdust was successfully prepared, verified by FTIR and X-ray photoelectron spectroscopy detailed analysis. Pretreatment of cottonseed meal and sawdust at mild conditions was made to obtain cottonseed protein, purified and oxidized cellulose. Structure of these treated samples was characterized by particle size distribution, FTIR and wide angle X-ray diffraction. When adding 15% of the oxidized cellulose into cottonseed protein, the dry bonding strength of the resulting adhesive reached 2.4 MPa on average; and the highest wet bonding strength of 1.1 MPa was found when 10% dialdehyde starch was used. The improvements of bonding strength as well as thermal stability of the prepared oxidized cellulose/cottonseed protein adhesives are largely ascribed to the formation of strong chemical bonds and their mechanical interlocking with plywood substrates. Both protein-oxidized cellulose and protein-oxidized starch cross-linking networks are formed in the adhesive system, combining tightly the adhesive components. The biodegradable adhesive fabricated in work provides a new approach for the development of all-biomass derived adhesives with properties comparable to the state-of-the-art protein derived bioadhesives, thus holding great potential as an alternative to formaldehyde-based resins in wood board and indoor panel bonding industries.

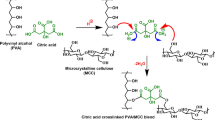

Graphical abstract

Similar content being viewed by others

References

Awaja F, Gilbert M, Kelly G, Fox B, Pigram PJ (2009) Adhesion of polymers. Prog Polym Sci 34:948–968. https://doi.org/10.1016/j.progpolymsci.2009.04.007

Bai Y, Zhao F, Shen J, Zhang Y (2021) Improvement of water resistance of wheat flour-based adhesives by thermal–chemical treatment and chemical crosslinking. J Appl Polym Sci 138:50458. https://doi.org/10.1002/app.50458

Barnes HA, Hutton JF, Walters K (1989) An introduction to rheology, vol 3. Elsevier, Amsterdam, pp 1–199

Chang Z, Mo L, Huang A, Li J, Zhang S (2020) Preparation of water-resistant soybean meal-based adhesives with waste paper cellulose via NaOH/urea pretreatment and oxidation. Cellulose 27:4455–4470. https://doi.org/10.1007/s10570-020-03076-y

Chen W, Yu H, Lee S-Y, Wei T, Li J, Fan Z (2018a) Nanocellulose: a promising nanomaterial for advanced electrochemical energy storage. Chem Soc Rev 47:2837–2872. https://doi.org/10.1039/c7cs00790f

Chen Y, Shi A, Wang Q (2018b) Peanut meal as plywood adhesives: preparation and characterization. J Adhes Sci Technol 32:2450–2463. https://doi.org/10.1080/01694243.2018.1483063

Chen C, Chen F, Liu B, Du Y, Liu C, **n Y, Liu K (2019) Peanut meal-based wood adhesives enhanced by urea and epichlorohydrin. R Soc Open Sci 6:191154. https://doi.org/10.1098/rsos.191154

Cheng HN, Kilgore K, Ford C, Fortier C, Dowd MK, He Z (2019) Cottonseed protein-based wood adhesive reinforced with nanocellulose. J Adhes Sci Technol 33:1357–1368. https://doi.org/10.1080/01694243.2019.1596650

Chu Y, Sun Y, Wu W, **ao H (2020) Dispersion properties of nanocellulose: a review. Carbohydr Polym 250:116892. https://doi.org/10.1016/j.carbpol.2020.116892

Curvello R, Raghuwanshi VS, Garnier G (2019) Engineering nanocellulose hydrogels for biomedical applications. Adv Colloid Interface Sci 267:47–61. https://doi.org/10.1016/j.cis.2019.03.002

Dou J, Karakoç A, Johansson L-S, Hietala S, Evtyugin D, Vuorinen T (2021) Mild alkaline separation of fiber bundles from eucalyptus bark and their composites with cellulose acetate butyrate. Ind Crops Prod 165:113436. https://doi.org/10.1016/j.indcrop.2021.113436

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

French AD (2017) Glucose, not cellobiose, is the repeating unit of cellulose and why that is important. Cellulose 24:4605–4609. https://doi.org/10.1007/s10570-017-1450-3

French AD, Kim HJ (2018) Cotton fiber structure. In: Fang D (ed) Cotton fiber physics, chemistry and biology. Springer, Berlin, pp 13–39

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20:583–588. https://doi.org/10.1007/s10570-012-9833-y

He Z, Cheng HN (2017) Evaluation of wood bonding performance of water-washed cottonseed meal-based adhesives with high solid contents and low press temperatures. J Adhes Sci Technol 31:2620–2629. https://doi.org/10.1080/01694243.2017.1313184

Heinrich LA (2019) Future opportunities for bio-based adhesives - advantages beyond renewability. Green Chem 21:1866–1888. https://doi.org/10.1039/c8gc03746a

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. https://doi.org/10.1039/C0NR00583E

Kang H, Wang Z, Wang Y, Zhao S, Zhang S, Li J (2019) Development of mainly plant protein-derived plywood bioadhesives via soy protein isolate fiber self-reinforced soybean meal composites. Ind Crops Prod 133:10–17. https://doi.org/10.1016/j.indcrop.2019.03.022

Li N, Wang Y, Tilley M, Bean SR, Wu X, Sun XS, Wang D (2011) Adhesive performance of sorghumprotein extracted from sorghum DDGS and flour. J Polym Environ 19:755–765. https://doi.org/10.1007/s10924-011-0305-5

Liu J, Korpinen R, Mikkonen KS, Willför S, Xu C (2014) Nanofibrillated cellulose originated from birch sawdust after sequential extractions: a promising polymeric material from waste to films. Cellulose 21:2587–2598. https://doi.org/10.1007/s10570-014-0321-4

Liu P, Mai C, Zhang K (2017) Formation of uniform multi-stimuli-responsive and multiblock hydrogels from dialdehyde cellulose. ACS Sustain Chem Eng 5:5313–5319. https://doi.org/10.1021/acssuschemeng.7b00646

Luo J, Zhou Y, Gao Q, Li J, Yan N (2020) From wastes to functions: a new soybean meal and bark-based adhesive. ACS Sustainable Chem Eng 8:10767–10773. https://doi.org/10.1021/acssuschemeng.0c02413

Mi Y, Sun Z, Gao D, Bai Y, Gao Z (2021) Positive impact of carbohydrate on the crosslinking, performance, and potential applications of defatted soybean flour-based adhesive. Int J Adhes Adhes 106:102811. https://doi.org/10.1016/j.ijadhadh.2021.102811

Mirzaie Yegane M, Hashemi F, Vercauteren F, Meulendijks N, Gharbi R, Boukany PE, Zitha P (2020) Rheological response of a modified polyacrylamide–silica nanoparticles hybrid at high salinity and temperature. Soft Matter 16:10198–10210. https://doi.org/10.1039/D0SM01254H

Mokhothu TH, John MJ (2015) Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr Polym 131:337–354. https://doi.org/10.1016/j.carbpol.2015.06.027

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082. https://doi.org/10.1021/ja0257319

Qu Y, Guo Q, Li T, Zhang Y, Gao Q, Liu H, Wang Q (2021) A novel environmentally friendly hot-pressed peanut meal protein adhesive. J Clean Prod 327:129473

Salarbashi D, Bazeli J, Tafaghodi M (2019) Environment-friendly green composites based on soluble soybean polysaccharide: a review. Int J Biol Macromol 122:216–223. https://doi.org/10.1016/j.ijbiomac.2018.10.110

Schmidt V, Giacomelli C, Soldi V (2005) Thermal stability of films formed by soy protein isolate–sodium dodecyl sulfate. Polym Degrad Stab 87:25–31. https://doi.org/10.1016/j.polymdegradstab.2004.07.003

Si X et al (2017) A strategy for generating high-quality cellulose and lignin simultaneously from woody biomass. Green Chem 19:4849–4857. https://doi.org/10.1039/C7GC02492D

Sun B, Hou Q, Liu Z, Ni Y (2015) Sodium periodate oxidation of cellulose nanocrystal and its application as a paper wet strength additive. Cellulose 22:1135–1146. https://doi.org/10.1007/s10570-015-0575-5

Thomas B et al (2018) Nanocellulose, a versatile green platform: from biosources to materials and their applications. Chem Rev 118:11575–11625. https://doi.org/10.1021/acs.chemrev.7b00627

Trisant PN, Gunardi I, Sumarno (2020) The influence of hydrolysis time in hydrothermal process of cellulose from sengon wood sawdust. Macromol Symp 391:2000016. https://doi.org/10.1002/masy.202000016

Wang Z, Kang H, Liu H, Zhang S, **a C, Wang Z, Li J (2020) Dual-network nanocross-linking strategy to improve bulk mechanical and water-resistant adhesion properties of biobased wood adhesives. ACS Sustain Chem Eng 8:16430–16440. https://doi.org/10.1021/acssuschemeng.0c04913

Wei X, Wang X, Li Y, Ma Y (2017) Properties of a new renewable sesame protein adhesive modified by urea in the absence and presence of zinc oxide. RSC Adv 7:46388–46394. https://doi.org/10.1039/c7ra07578b

Wei X, Ma Y, Wang X (2021a) Performance of a formaldehyde-free sesame protein adhesive modified by urea in the presence and absence of glyoxal. BioResources 16:3121–3136. https://doi.org/10.15376/biores.16.2.3121-3136

Wei Z, Zhang Y, Ma X, Wang W (2021) Insight into the high-efficiency adsorption of pyrene by schiff base porous polymers: modelling and mechanism. Polymer 220:123576. https://doi.org/10.1016/j.polymer.2021.123576

Wu H, Chen F, Liu M, Wang J (2017) Preparation of microcrystalline cellulose by liquefaction of eucalyptus sawdust in ethylene glycol catalyzed by acidic ionic liquid. BioResources 12:3766–3777. https://doi.org/10.15376/biores.12.2.3766-3777

** X, Pizzi A, Gerardin C, Liao J, Amirou S, Abdalla S (2021) Glutaraldehyde-wheat gluten protein adhesives for wood bonding. J Adhes 97:88–100. https://doi.org/10.1080/00218464.2019.1630821

**a Q et al (2021) A strong, biodegradable and recyclable lignocellulosic bioplastic. Nat Sustain 4:627–635. https://doi.org/10.1038/s41893-021-00702-w

Xue Y, Mou Z, **ao H (2017) Nanocellulose as a sustainable biomass material: structure, properties, present status and future prospects in biomedical applications. Nanoscale 9:14758–14781. https://doi.org/10.1039/c7nr04994c

Yokozeki T, Carolin Schulz S, Buschhorn ST, Schulte K (2012) Investigation of shear thinning behavior and microstructures of MWCNT/epoxy and CNF/epoxy suspensions under steady shear conditions. Eur Polym J 48:1042–1049. https://doi.org/10.1016/j.eurpolymj.2012.03.013

Yue HB, Cui YD, Shuttleworth PS, Clark JH (2012) Preparation and characterisation of bioplastics made from cottonseed protein. Green Chem 14:2009. https://doi.org/10.1039/c2gc35509d

Yue H, Rubalcaba JC, Cui Y, Fernández-Blázquez JP, Yang C, Shuttleworth PS (2019) Determination of cross-sectional area of natural plant fibres and fibre failure analysis by in situ SEM observation during microtensile tests. Cellulose 26:4693–4706. https://doi.org/10.1007/s10570-019-02428-7

Yue H, Zheng Y, Zheng P, Guo JW, Fernandez JP, Clark J, Cui Y (2020a) On the improvement of properties of bioplastic composites derived from wasted cottonseed protein by rational cross-linking and natural fiber reinforcement. Green Chem 22:8642–8655. https://doi.org/10.1039/D0GC03245J

Yue L, Shi R, Yi Z, Shi SQ, Gao Q, Li J (2020b) A high-performance soybean meal-based plywood adhesive prepared via an ultrasonic process and using significantly lower amounts of chemical additives. J Clean Prod 274:123017. https://doi.org/10.1016/j.jclepro.2020.123017

Zhang B, Fan B, Huo P, Gao Z-H (2017) Improvement of the water resistance of soybean protein-based wood adhesive by a thermo-chemical treatment approach. Int J Adhes Adhes 78:222–226. https://doi.org/10.1016/j.ijadhadh.2017.08.002

Zhang B, Jiang S, Du G, Cao M, Zhou X, Wu Z, Li T (2021) Polyurea-formaldehyde resin: a novel wood adhesive with high bonding performance and low formaldehyde emission. J Adhes 97:477–492. https://doi.org/10.1080/00218464.2019.1679631

Acknowledgments

This work was supported by Natural Science Foundation of Guangdong Province (2022A1515011500), National Natural Science Foundation of China (21706039), Guangdong Provincial Key Laboratory of Plant Resources Biorefinery (2021B1212040011), and China Scholarship Council.

Funding

Natural Science Foundation of Guangdong Province (2022A1515011500), National Natural Science Foundation of China (21706039), Guangdong Provincial Key Laboratory of Plant Resources Biorefinery (2021B1212040011), and China Scholarship Council.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by CX. and HY. The first draft of the manuscript was written by HY., funding acquisition by HY., and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yue, H., Xu, C., Yao, J. et al. Characterization and properties of plywood bioadhesive derived from cottonseed protein and sawdust cellulose. Cellulose 29, 5869–5881 (2022). https://doi.org/10.1007/s10570-022-04611-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04611-9