Abstract

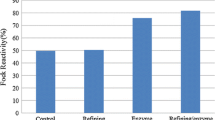

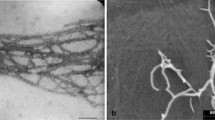

The combined effect of enzymatic treatment (biobeating) and NFC addition on the mechanical and physical properties of a papermaking pulp suspension was investigated. The influence of pH, consistency of pulp and reaction time of the enzyme on the pulp strength was evaluated by measuring the breaking length of paper sheets made thereof. The results showed that the enzymatic treatment improved mechanical properties of fibres without modifying drainability. After biobeating, NFC was added to the enzyme-treated pulps. Mechanical properties were enhanced, obtaining length at break values similar to those observed in commercial printing/writing paper. Opacity remained constant, whereas porosity was gradually reduced as more amount of NFC was added. The presence of NFC also reduced drainability, although it remained at suitable levels for the papermaking industry. The results suggest that the combination of biobeating and NFC addition can be considered as an alternative to mechanical beating.

Similar content being viewed by others

References

Ahola S, Österberg M, Laine J (2008) Cellulose nanofibrils-adsorption with poly(amideamine) epichlorohydrine studied by QCM-D and application as a paper strength additive. Cellulose 15:303–314

Bajpai P, Bajpai PK (1998) Deinking with enzymes: a review. Tappi J 81:111–117

Besbes I, Rei Vilar M, Boufi S (2011) Nanofibrillated cellulose from alfa, eucalyptus and pine fibers: preparation, characteristics and reinforcing potential. Carbohydr Polym 86:1198–1206

Cadena E, Chriac AI, Pastor FI, Diaz P, Vidal T, Torres AL (2010) Use of cellulases and recombinant cellulose binding domains forbeating TCF kraft pulp. Biotechnol Prog 26(4):960–967

Carrasco F, Mutjé P, Pèlach MA (1996) Beating of bleached cellulosic pulps: characterization by application of the colloidal titration technique. Wood Sci Technol 30(4):227–236

Dasgupta S (1994) Mechanism of paper tensile-strength development due to pulp beating. Tappi J 77(6):158–164

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nordic Pulp Paper Res J 23(3):299–304

García O, Torres AL, Colom JF, Pastor FIJ, Díaz P, Vidal T (2002) Effect of cellulase-assisted beating on the properties of dried and never-dried Eucalyptus pulp. Cellulose 9:115–125

González I, Boufi S, Pèlach MA, Alcalà M, Vilaseca F, Mutjè P (2012) Nanofibrillated cellulose as paper additive in eucalyptus pulps. Bioresources 7(4):5167–5180

Hubbe MA, Heitmann JA (2007) Review of factors affecting the release of water from cellulosic fibers during paper manufacture. Bioresources 2:500–533

Hubbe MA, Venditti RA, Rojas OJ (2007) What happens to cellulosic fibres during papermaking and recycling? A review. Bioresources 2(4):739–788

Huber P, Carré B, Petit-Conil M (2008) The influence of TMP fibre flexibility on flocculation and formation. Bioresources 3(4):1218–1227

Hurter Consult Incorporated (2002) 100% nonwood fiber content papers—Part 3: bleached papers physical properties. http://www.hurterconsult.como/nonwood_paper_4.htm

Joseleau J-P, Chevalier-Billosta V, Ruel K (2012) Interaction between microfibrillar cellulose fines and fibres: influence on pulp qualities and paper sheet properties. Cellulose 19:769–777

Kibblewhite PR, Clark TA (1996) Enzymatic modification of radiata pine kraft fibre and handsheet properties. Appita J 49:390–396

Kim HJ, Jo BM, Lee SH (2006) Potential for energy saving in beating of cellulase-treated kraft pulp. J Ind Eng Chem 12(4):578–583

Lecourt M, Meyer V, Sigoillot JC, Petit-Conil M (2010a) Energy reduction of beating by cellulases. Holzforschung 64:441–446

Lecourt M, Sigoillot JC, Petit-Conil M (2010b) Cellulase-assisted beating of chemical pulps: impact of enzymatic charge and beating intensity on energy consumption and pulp quality. Process Biochem 45:1274–1278

Lin M, Kilburn DG, Breuil C and Robertson AG (1995) Assessing changes in the specific surface area of kraft papermaking fibres with cellulase binding domain. In: 8th international symposium on wood and pul** chemistry, vol. 1, Helsinki. June 6–9, pp 645–652

Lumiainen J (1998) Beating of chemical pulp. In: Paulapuro H (ed) Papermaking science and technology, book 8 papermaking part 1, stock preparation and wet end. Fapet Oy, Helsinki

Lumme MS, Mansfield SD, Saddler JN (1999) The effects of hydrolytic enzyme treatments of 3 British Columbian interior fir kraft pulps differing in their initial fibre coarseness. Wood Fibre Sci 31:385–393

Mansfield SD, Dejong E, Stephens RS, Saddler JN (1997) Physical characterization of enzymatically modified kraft pulp fibres. J Biotechnol 57:205–216

Marais A, Wågberg L (2012) The use of polymeric amines to enhance the mechanical properties of lignocellulosic fibrous networks. Cellulose 19(4):1437–1447

Minor JL, Atalla RH and Harten TM (1991) Improving interfiber bonding of recycled fibers. Prod 1991 recycling forum, 115–122

Molin U, Daniel G (2004) Effects of beating on the fibre structure of kraft pulps as revealed by FE-SEM and TEM: influence of alkaline degradation. Holzforschung 58:226–232

Norell M, Johansson K and Persson M (1999) Retention and drainage. In: Neimo L (ed) Papermaking science and technology, book 4: papermaking chemistry. Fapet Oy, Helsinki, Finland, pp 43–81

Oksanen T, Pere J, Buchert J, Viikari L (1997) The effect of Trichoderma reesei cellulases and hemicellulases on the paper technical properties of never-dried bleached kraft pulp. Cellulose 4:329–339

Pastor FIJ, Pujol X, Blanco A, Vidal T, Torres AL, Diaz P (2001) Molecular cloning and characterization of a multi domain endoglucanase from Paenibacillus sp. BP-23. Evaluation of its performance on pulp beating. Appl Microbiol Biotechnol 55:61–68

Pere J, Siika-aho M, Buchert J, Viikari L (1995) Effect of Trichodermareesei cellulases on the fibre properties of kraft pulp. Tappi J 78:71–78

Roncero MB, Vidal T, Torres AL and Colom JF (1996) Use of xylanase in the totally chlorine free bleaching of eucalyptus kraft pulp. In: ACS symposium series no. 655: Enzymes for pulp and paper processing, pp 219–227

Sehaqui H, Allais M, Zhou Q, Berglund L (2011) Wood cellulose biocomposites with fibrous structures at micro- and nanoscale. Compos Sci Technol 71:382–387

Skals PB, Krabek A, Nielsen PH, Wenzel H (2008) Environmental assessment of enzyme assisted processing in pulp and paper industry. Int J LCA 13(2):124–132

Taipale T, Österberg M, Nykänen A, Ruokolainen J, Laine J (2010) Effect of microfibrillated cellulose and fines on the drainage of kraft pulp suspension and paper strength. Cellulose 17:1005–1020

Torres AL, García O, Colom JF, Pastor FIJ, Díaz P and Roncero MaB (1999) Cellulase-assisted beating of fibres and handsheet properties. In: 27th Eucepa conference. Crossing the millennium frontier emerging technical and scientific challenges. Grenoble, October 11–14, pp 47–52

Torres AL, MaB Roncero, Colom JF, Pastor FIJ, Blanco A, Vidal T (2000) Effect of a novel enzyme on fibre morphology during ECF bleaching of oxygen delignified eucalyptus kraft pulps. Bioresour Technol 74:135–140

Torres CE, Negro C, Fuente E, Blanco A (2012) Enzymatic approaches in paper industry for pulp beating and biofilm control. Appl Microbiol Biotechnol 96:327–344

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, Handa K (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153

Yoo S, Hsieh JS (2010) Enzyme-assisted preparation of fibrillated cellulose fibers and its effect on physical and mechanical properties of paper sheet composites. Ind Eng Chem Res 49(5):2161–2168

Acknowledgments

The authors are thankful to the Spanish Ministry of Science and Innovation for the financial support given by the projects CTQ2010-21660-C03-03 and CTM2011-28506-C02-01 to develop this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

González, I., Vilaseca, F., Alcalá, M. et al. Effect of the combination of biobeating and NFC on the physico-mechanical properties of paper. Cellulose 20, 1425–1435 (2013). https://doi.org/10.1007/s10570-013-9927-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9927-1