Abstract

Objectives

To convert α-acetolactate into acetoin by an α-acetolactate decarboxylase (ALDC) to prevent its conversion into diacetyl that gives beer an unfavourable buttery flavour.

Results

We constructed a whole Saccharomyces cerevisiae cell catalyst with a truncated active ALDC from Acetobacter aceti ssp xylinum attached to the cell wall using the C-terminal anchoring domain of α-agglutinin. ALDC variants in which 43 and 69 N-terminal residues were absent performed equally well and had significantly decreased amounts of diacetyl during fermentation. With these cells, the highest concentrations of diacetyl observed during fermentation were 30 % less than those in wort fermented with control yeasts displaying only the anchoring domain and, unlike the control, virtually no diacetyl was present in wort after 7 days of fermentation.

Conclusions

Since modification of yeasts with ALDC variants did not affect their fermentation performance, the display of α-acetolactate decarboxylase activity is an effective approach to decrease the formation of diacetyl during beer fermentation.

Similar content being viewed by others

References

ASBC Methods of Analysis, online. Beer method 25. Diacetyl. Approved (2011) rev. (2014). American Society of Brewing Chemists, St. Paul doi:10.1094/ASBCMOA-Beer-25

ASBC Methods of Analysis, online. Beer method 4. Alcohol. Approved (1958), rev. (2004). American Society of Brewing Chemists, St. Paul doi:10.1094/ASBCMOA-Beer-4

ASBC Methods of Analysis, online. Beer method 5. Real Extract. Approved (1958), rev. (1982). American Society of Brewing Chemists, St. Paul doi:10.1094/ASBCMOA-Beer-5

Blomqvist K, Suihko ML, Knowles J, Penttila M (1991) Chromosomal integration and expression of two bacterial α-acetolactate decarboxylase genes in Brewers’ yeast. Appl Environ Microbiol 57:2796–2803

Ghaemmaghami S et al (2003) Global analysis of protein expression in yeast. Nature 425:737–741

Gibson B, Krogerus K, Ekberg J, Monroux A (2015) Variation in α-acetolactate production within the hybrid lager yeast group Saccharomyces pastorianus and affirmation of the central role of the ILV6 gene. Yeast 32:301–316

Gietz RD, Schiestl RH, Willems AR, Woods RA (1995) Studies of the transformation of intact yeast cells by the LiAc/SS-DNA/PEG procedure. Yeast 11:355–360

Godtfredsen SE, Ottesen M (1982) Maturation of beer with α-acetolactate decarboxylase. Carlsberg Res Commun 47:93–102

Godtfredsen SE, Lorck H, Sigsgaard P (1983) On the occurrence of α-acetolactate decarboxylases among microorganisms. Carlsberg Res Commun 48:239–247

Godtfredsen SE, Rasmussen AM, Ottesen M, Mathiasen T, Ahrenst-Larsen B (1984) Application of the acetolactate decarboxylase from Lactobacillus casei for accelerated maturation of beer. Carlsberg Res Commun 49:69–74

Goelling D, Stahl U (1988) Cloning and expression of an alpha-acetolactate decarboxylase gene from Streptococcus lactis subsp diacetylactis in Escherichia coli. Appl Environ Microbiol 54:1889–1891

Inoue T (2008) Diacetyl in fermented foods and beverages. American Society of Brewing Chemists, St. Paul, p 139

Inoue T, Yamamoto Y (1970) Diacetyl and beer fermentation. Proc Am Soc Brew Chem 28:198–208

Kotrba P, Ruml T (2010) Surface display of metal fixation motifs of bacterial P1-type ATPases specifically promotes biosorption of Pb2+ by Saccharomyces cerevisiae. Appl Environ Microbiol 76:2615–2622

Krogerus K, Gibson BR (2013) 125th anniversary review: diacetyl and its control during brewery fermentation. J Inst Brew 119:86–97

Mumberg D, Mueller R, Funk M (1995) Yeast vectors for the controlled expression of heterologous proteins in different genetic backgrounds. Gene 156:119–122

Murai T et al (1997) Construction of a starch-utilizing yeast by cell surface engineering. Appl Environ Microbiol 63:1362–1366

Petruzzi L, Corbo MR, Sinigaglia M, Bevilacqua A (2016) Brewer’s yeast in controlled and uncontrolled fermentations, with a focus on novel, nonconventional, and superior strains. Food Rev Int 32:341–363

Ruehle G et al (2014) Headspace gas chromatography/electron capture detector analysis of total vicinal diketones in beer. J Am Soc Brew Chem 72:305–306

Sone H, Fujii T, Kondo K, Shimizu F (1988) Nucleotide sequence and expression of the enterobacter aerogenes α-acetolactate decarboxylase gene in brewers’ yeast. Appl Environ Microbiol 54:38–42

Tanaka T, Kondo A (2015) Cell surface engineering of industrial microorganisms for biorefining applications. Biotechnol Adv 33:1403–1411

Tanaka T, Yamada R, Ogino C, Kondo A (2012) Recent developments in yeast cell surface display toward extended applications in biotechnology. Appl Microbiol Biotechnol 95:577–591

Vinopal S, Ruml T, Kotrba P (2007) Biosorption of Cd2+ and Zn2+ by cell surface-engineered Saccharomyces cerevisiae. Int Biodeterior Biodegrad 60:96–102

Vogel J, Wackerbauer K, Stahl U (1995) Improvement of beer brewing by using genetically modified yeast. ACS Symp Ser 605:160–170

Yamano S, Kondo K, Tanaka J, Inoue T (1994a) Construction of a brewer’s yeast having α-acetolactate decarboxylase gene from Acetobacter aceti ssp xylinum integrated in the genome. J Biotechnol 32:173–178

Yamano S, Tanaka J, Inoue T (1994b) Cloning and expression of the gene encoding α-acetolactate decarboxylase from Acetobacter aceti ssp xylinum in brewer’s yeast. J Biotechnol 32:165–171

Acknowledgments

This work was supported by the project TE02000177 “Centre for Innovative Use and Strengthening of Competitiveness of Czech Brewery Raw Materials and Products” of the Technology Agency of the Czech Republic.

Supporting information

Supplementary Table 1—Fermentation performance of S. cerevisiae W303-1A strains transformed with indicated plasmids.

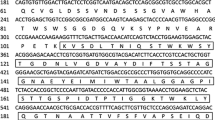

Supplementary Fig. 1—Surface display of ALDC130 and ALDC208 fusions to V5-AGα1Cp expressed in S. cerevisiae W303-1A.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cejnar, R., Hložková, K., Kotrba, P. et al. Surface-engineered Saccharomyces cerevisiae displaying α-acetolactate decarboxylase from Acetobacter aceti ssp xylinum . Biotechnol Lett 38, 2145–2151 (2016). https://doi.org/10.1007/s10529-016-2205-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-016-2205-1