Abstract

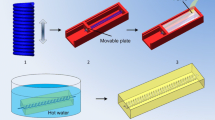

In recent years, the mechanism based on changing the cross-sectional shape of long and straight channels for increasing mixing efficiency has reached a bottleneck, while the vortex effect brought by curved channels has become a hot topic in current mixer research. The vortex effect should be fully utilized in the mixing process. Inspired by the spiral structure as well as splitting and reorganization, a passive three-dimensional double-helical structure micro-mixer was proposed. It is printed by FDM (fused deposition) technology. First, a model of the double-helix structure was printed with HIPS (high impact polystyrene) material, which was supported by PVA (polyvinyl alcohol) material. The mixing experiments showed that the three-dimensional (3D) double-helix structure could increase the mixing efficiency to 90.6%, while the mixing efficiency of the conventional two-dimensional (2D) T-shaped structure was only 78.5%. In this paper, the effects of the number of turns, pitch, diameter, staggering angle, and flow rate on the mixing effect are compared separately. The results show that the change of staggering angle has a better effect on the improvement of mixing efficiency.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Chen X, Shen J (2017) Numerical and experimental investigation on splitting-and-recombination micromixer with E-shape mixing units. Microsyst Technol 23(10):4671–4677

Chen X, Li T, Zeng H, Hu Z, Fu B (2016) Numerical and experimental investigation on micromixers with serpentine microchannels. Int J Heat Mass Transf 98:131–140

Chen X, Lv H (2022) Numerical study on bilateral stagger Cantor fractal baffles micromixer. Iran J Chem Chem Eng 41(7):2496–2504

Chung CK, Shih TR, Chang CK, Lai CW, Wu BH (2011) Chem Eng J 168:790

Cui WW, Zhang H, Zhang HX, Yang Y, He MH, Qu HM, Pang W, Zhang DH, Duan XX (2016) Localized ultrahigh frequency acoustic fields induced micro-vortices for submilliseconds microfluidic mixing. Appl Phys Lett 109:253503

Douroum E, Laouedj S, Benazza A, Kouadri A (2020) Cooling of a surface with constant heat flow using a synthetic jet actuator. UPB Sci Bull Ser D Mech Eng 82(4):293–306

Feng XS, Ren YK, Hou LK, Tao Y, Jiang TY, Li WY, Jiang HY (2019) Tri-fluid mixing in a microchannel for nanoparticle synthesis. Lab Chip 19:2936–2946

Harmon NJ, Wohlgenannt M, Flatte ME (2016) Manipulation of the electroluminescence of organic light-emitting diodes via fringe fields from patterned magnetic domains. Appl Phys Lett 109:243303

Jahn A, Stavis SM, Hong JS, Vreeland WN, Devoe DL, Gaitan M (2010) Microfluidic mixing and the formation of nanoscale lipid vesicles. ACS Nano 4:2077–2087

Lee KY, Park S, Lee YR, Chung SK (2016a) Magnetic droplet microfluidic system incorporated with acoustic excitation for mixing enhancement. Sens Actuators A Phys 243:59–65

Lee CY, Wang WT, Liu CC, Fu LM (2016b) Passive mixers in microfluidic systems: a review. Chem Eng J 288:146–160

Lv HL, Chen XY, Zeng XW (2021) Optimization of micromixer with Cantor fractal baffle based on simulated annealing algorithm. Chaos Solitons Fractals 148:111048

Mahmud MR (2021) Numerical investigation of liquid–liquid mixing in modified T mixer with 3D obstacles. J Eng Adv 2(02):87–94

Mashaei PR, Asiaei S, Hosseinalipour SM (2020) Mixing efficiency enhancement by a modified curved micromixer; a numerical study. Chem Eng Process 154:108006

Modarres P, Tabrizian M (2020) Phase-controlled field-effect micromixing using AC electroosmosis. Microsyst Nanoeng 6(1–1):1

Morteza B, Ashani MN, Azam U (2020) Active and passive micromixers: a comprehensive review. Chem Eng Proces: Process Intensif 147:107771

Niculescu AG, Chircov C, Bîrcă AC, Grumezescu AM (2021) Fabrication and applications of microfluidic devices: a review. Inter J Mol Sci 22(4):1–26

Shanko ES, van de Burgt Y, Anderson DP, den Toonder MJ (2019) Microfluidic magnetic mixing at low Reynolds numbers and in stagnant fluids. Micromachines 10:731

Sudarsan AP, Ugaz VM (2006) Multivortex micromixing. Proc Natl Acad Sci USA 103:7228–7233

Wang JY, Liu C, Xu Z, Li YK, Liu YL (2014) Ion-enrichment and ion-depletion of nanochannels based on electrochemical potential in a micro-nanofluidic chip. Microsyst Technol 20(3):5–39

Wang JY et al (2022) Efficient mixing of microfluidic chip with a three-dimensional spiral structure. ACS Omega 7(1):1527–1536

Zhang CY, Brunet P, Royon L, Guo XF (2021) Mixing intensification using sound–driven micromixer with sharp edges. Chem Eng J 410:128252

Zhao SG, Huang PH, Zhang HY, Rich J, Bachman H, Ye J, Zhang WF, Chen CY, **e ZM, Tian ZH, Kang PT, Fu H, Huang TJ (2021) Fabrication of tunable, high-molecular-weight polymeric nanoparticles via ultrafast acoustofluidic micromixing. Lab Chip 21:2453–2463

Zhu S, Wu D, Han Y, Wang CL, **ang N, Ni ZH (2020) Inertial microfluidic cube for automatic and fast extraction of white blood cells from whole blood. Lab Chip 20:244–252

Funding

This project was supported by the National Natural Science Foundation of China (Grant No. 51505077), Project Agreement for Science and Technology Development of Jilin Province (JJKH20200105KJ), and the Science and Technology Innovation Development Project of Jilin City (201750230, 20166013, 20166012).

Author information

Authors and Affiliations

Contributions

Liu Huan mainly revised the manuscript, which was reviewed by all the authors.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, H., Li, G., Liu, H. et al. A three-dimensional double-helical structure microfluidic chip with efficient mixing. Microfluid Nanofluid 27, 48 (2023). https://doi.org/10.1007/s10404-023-02658-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-023-02658-z