Abstract

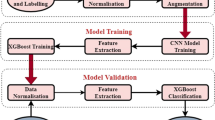

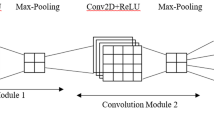

Waste-to-energy facilities play a major role in realizing volume reduction and stabilization of organic waste, as well as energy recovery and utilization. In the operational management of waste-to-energy plant, stable combustion is required for preventing emission of hazardous substances and for realizing efficient energy recovery. It is known that proper mixing and homogenization of the wastes in the bunker by waste crane is crucial for achieving stable combustion, and this makes limitation on rate of automatic crane operation due to unavoidable visual inspection of waste mixing status and necessary manual intervention by crane operators, which was dependent on the experience and judgement of the operators. To increase the rate of automatic crane operation, the authors developed an innovative automatic crane operation system with an artificial intelligence (AI) that uses deep learning to identify waste types inside a waste bunker, as well as an advanced control device that recognizes optimal crane operation based on the inference results made by the AI. The AI is developed by applying semantic segmentation algorithm to waste bunker images as training data, for which labels of each waste types are added. The F1 scores of the trained AI were high enough and close to 1 for each type of waste. The AI and the system were implemented at a municipal waste-to-energy facility in Japan and a 6-day demonstration experiment was carried out. An automatic operation rate of about 90% was achieved during the demonstration experiment period, without adversely affecting waste combustion or requiring constant monitoring of the bunker by an operator. Thereafter, the experimental plant continued stable operation using the AI based system.

Similar content being viewed by others

References

The World Bank (2018) What a waste 2.0: a global snapshot of solid waste management to 2050. https://doi.org/10.1596/978-1-4648-1329-0.

Ferronato N, Torretta V (2019) Waste mismanagement in develo** countries: a review of global issues. Int J Environ Res Public Health 16:1060. https://doi.org/10.3390/ijerph16061060

Denison RA (1996) Environmental life-cycle comparisons of recycling, landfilling, and incineration: a review of recent studies. Annu Rev Energy Environ 1996(21):191–237

Bosmans A, Vanderreydt I, Geysen D, Helsen L (2013) The crucial role of waste-to energy technologies in enhanced landfill mining: a technology review. J Clean Prod 55(2013):10–23. https://doi.org/10.1016/j.jclepro.2012.05.032

Sun L, Fujii M, Tasaki T, Dong H, Ohnishi S (2018) Improving waste to energy rate by promoting an integrated municipal solid-waste management system. Resour Conserv Recycl 136:289–296. https://doi.org/10.1016/j.resconrec.2018.05.005

Boloy RAM, da Cunha Reis A, Rios EM, de Araújo Santos Martins J, Soares LO, de Sá Machado VA, de Moraes DR (2021) Waste-to-energy technologies towards circular economy: a systematic literature review and bibliometric analysis. Water Air Soil Pollut 232, Article number: 306. https://doi.org/10.1007/s11270-021-05224-x

Oura Y, Yamase K, Kawabata K, Onuki Y, Hirabayashi T (2017) Operational effect of waste crane automatic operation system using waste pit three-dimensional map technology. In: The 28th annual conference of japan society of material cycles and waste management, pp 271–272. https://doi.org/10.14912/jsmcwm.28.0_271

Iwasaki Y, Ogura Y, Mukai T, Okuda H, Usui K (2016) Technology of smart automatic combustion control system. In: The 27th annual conference of japan society of material cycles and waste management, pp 315–316. https://doi.org/10.14912/jsmcwm.27.0_315

Fukuma Y, Fujikawa H, Matsuda Y, Watase M, Matsuto T (2018) Estimating heat generation and heating values by exhaust gas composition for a municipal solid waste incinerator. J Jpn Soc Mater Cycles Waste Manag 29:8–19. https://doi.org/10.3985/jjsmcwm.29.8

Mackin K, Fujiyoshi M, Dai Y, Tomaru M (2017) Three-dimensional waste pit management and crane control system using machine learning. In: 33rd fuzzy system symposium, pp 31–34. https://doi.org/10.14864/fss.33.0_31

Takeda K, Yamamoto H, Aoki I, Tomioka S, Hashimoto T, Kawabata K (2018) Current status and technical outlines of ICT and AI technology utilization in MSW treatment facilities. Mater Cycles Waste Manag Res 29(3):228–236. https://doi.org/10.3985/mcwmr.29.228

Mori Y (2018) Introduction to machine learning and its application to medical images. Med Imaging Inf Sci 35(3):42–47. https://doi.org/10.11318/mii.35.42

Hoshino K, Nakano M, Sekine S, Motegi K, Shiraishi Y (2018) An image recognition and distance measurement method based on machine learning for autonomous driving of next generation automatic guided vehicles. In: The 32nd JIEP annual meeting, pp 341–343. https://doi.org/10.11486/ejisso.32.0_341

Omori T, Itoh T, Arai S, Takahashi Y (2018) Image processing system for cattle health monitoring. In: 2018 JSPE spring conference, pp 261–262. https://doi.org/10.11522/pscjspe.2018S.0_261

Garcia-Garcia A, Orts-Escolano S, Oprea SO, Villena-Martinez V, Garcia-Rodriguez J (2017) A review on deep learning techniques applied to semantic segmentation. https://doi.org/10.48550/ar**v.1704.06857

Yokoyama A, Umezawa T, Ito K (2019) Automatic crane system with waste identification AI. Ebara Engineering Review No 258

Chicco D, Jurman G (2020) The advantages of the Matthews correlation coefficient (MCC) over F1 score and accuracy in binary classification evaluation. BMC Genom 21:6. https://doi.org/10.1186/s12864-019-6413-7

Suzuki H, Nakayama E, Sakurai K (2017) Delivery of high-efficiency waste-to-energy plant and waste heat utilization facility for Funabashi City—contribution to establish the recycling-oriented society in the local community. Ebara Engineering Review No 254

Tsukamoto K, Nishiyama K, Sasaki M, Kanazawa M, Sato K, Hirakawa Y (2016) Construction of municipal waste treatment plant “Clean Plaza Yokote”. Ebara Engineering Review No 252

Akiba N, Iguchi T (2015) Stoker-type waste incineration plant for Iwamizawa, Hokkaido construction and delivery of Iwamizawa environment clean plaza. Ebara Engineering Review No 249

Okamoto T, Oishi T, Shiratori J, Katayama K, Nita Y, Takahashi T (2017) Construction of municipal solid waste treatment plant “Central Waste Management Center 70-ton/day Incinerator”. Ebara Engineering Review No 253

Koura Y, Hirabayashi T, Kawabata K, Motoyama M, Masuoka T, Yaji H, Hirako M, Oda H (2024) Demonstration results of Waste pit & Crane 3D system and report on waste crane remote operation at multiple facilities (in Japanese). In: 45th Japan waste management association annual meeting, pp 186–188

Gunji S, Matsumoto S, Iwashita S, Setoguchi N, Takahashi K, Sakurai A, Terasawa Y, Egusa T (2024) Pit crane advanced automatic operation system with optimal route search (in Japanese). In: 45th Japan waste management association annual meeting, pp 192–194

Sakai M, Machida J, Tomaru H (2021) Advancement and generalization of waste identification AI through additional learning methods (in Japanese). In: 43th Japan waste management association annual meeting, pp 153–155

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ito, K., Fujiwara, T., Cho, H. et al. Waste-to-energy plant evaluation of combustion stability using an automatic crane system with AI-based waste identification. J Mater Cycles Waste Manag 26, 1997–2008 (2024). https://doi.org/10.1007/s10163-024-01920-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-024-01920-y