Abstract

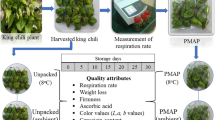

Refrigerator chill compartments with volumes of 22-L were fabricated, which had different gas tightness properties to gas or water vapor, ranging from 1,770 to 107,000 mL/hr·m2·atm in CO2 permeance at 25°C. Those compartments were filled with prepared fresh vegetables, and then their ability to preserve the quality at 3°C for 14 days was compared. The internal atmosphere and humidity were monitored together with the stored produce quality. The air-tight compartment with the lowest permeance created an atmosphere slightly different from air (CO2 0.8–1.6%; O2 19.7–20.4%), while the other ones had atmospheres of normal air. The relative humidity of the compartments ranged from 52 to 97%. Two air-tight compartments, maintaining a relative humidity mostly higher than 95%, preserved the produce better than the conventional open type one, with reduced weight loss and better retentions of ascorbic acid and chlorophyll.

Similar content being viewed by others

References

Thompson AK. Controlled Atmosphere Storage of Fruits and Vegetables. CAB International, Wallingford, UK. pp. 14–55 (1998)

Dijkink BH, Tomassen MM, Willemsen JHA, van Doorn WG. Humidity control during bell pepper storage, using a hollow fiber membrane contactor system. Postharvest Biol. Tec. 32: 311–320 (2004)

Evans J. Consumer perceptions and practice in the handling of chilled foods. pp. 1–24. In: Sous Vide and Cook-Chill Processing for the Food Industry. Ghazala S (ed). Aspen Publishers, Gaithersburg, MD, USA (1998)

Bogh-Sorensen L, Olsson P. The chill chain. pp. 245–267. In: Chilled Foods, the State of the Art. Gormley TR (ed). Elsevier Applied Science, London, UK (1990)

Masjuki HH, Saidur R, Choudhury IA, Mahlia TMI. Factors effecting energy consumption of household refrigerator-freezers. pp. 92–96. In: TENCON 2000 Proceedings September 24–27, Renaissance-New World Hotel, Kuala Lumpur, Malaysia. IEEE, Piscataway, NJ, USA (2000)

Hermes CJL, Melo C, Knabben FT, Gonçalves JM. Prediction of the energy consumption of household refrigerators and freezers via steady-state simulation. Appl. Energ. 86: 1311–1319 (2009)

Kader AA, Saltveit ME. Atmosphere modification. pp. 229–246. In: Postharvest Physiology and Pathology of Vegetables. Bartz JA, Brecht JK (eds). Marcel Dekker, New York, NY, USA (2003)

Yam KL, Lee DS. Design of modified atmosphere packaging for fresh produce. pp. 55–73. In: Active Food Packaging. Rooney ML (ed). Blackie Academic & Professional, London, UK (1995)

Seo GH, Chung SK, An DS, Lee DS. Permeabilities of Korean earthenware containers and their potential for packaging fresh produce. Food Sci. Biotechnol. 14: 82–88 (2005)

Lee DS, Yam KL, Piergiovanni L. Food Packaging Science and Technology. CRC Press, Boca Raton, FL, USA. pp. 79–108 (2008)

Ozdemir I, Monnet F, Gouble B. Simple determination of the O2 and CO2 permeances of microperforated pouches for modified atmosphere packaging of respiring foods. Postharvest Biol. Tec. 36: 209–213 (2005)

Gonzalez J, Ferrer A, Oria R, Salvador ML. Determination of O2 and CO2 transmission rates through microperforated films for modified atmosphere packaging of fresh fruits and vegetables. J. Food Eng. 86: 194–201 (2008)

AOAC. Official Methods of Analysis. Vol. 16th ed. Method 967.21. Association of Official Analytical Chemists, Washington, DC, USA (1995)

MacKinney GJ. Absorption of light by chlorophyll solutions. J. Biol. Chem. 140: 315–322 (1941)

Paull RE. Effect of temperature and relative humidity on fresh commodity quality. Postharvest Biol. Tec. 15: 263–277 (1999)

Wills RBH, McGlasson WB, Graham D, Lee TH, Hall EG. Postharvest. Van Nostrand Reinhold, New York, NY, USA. pp. 53–60 (1989)

Mahajan PV, Goswami TK. Enzyme kinetics based modelling of respiration rate for apple. J. Agr. Eng. Res. 79: 399–406 (2001)

Ben-Yehoshua S, Rodov V. Transpiration and water loss. pp. 111–159. In: Postharvest Physiology and Pathology of Vegetables. Bartz JA, Brecht JK (eds). Marcel Dekker, New York, NY, USA (2003)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, S.J., An, D.S., Kim, J. et al. Effect of gas tightness-controlled compartment system on quality kee** of fresh produce stored in household refrigerator. Food Sci Biotechnol 19, 1587–1592 (2010). https://doi.org/10.1007/s10068-010-0225-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-010-0225-5