Abstract

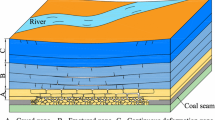

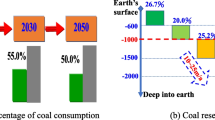

Liberating layer mining is often used in high gas and low permeability coal seam, but this mining method will produce a large number of gangues. If these gangues are stacked on the surface ground, they will not only pollute the environment but also increase the transportation cost for the gangue. Backfilling method is an effective way to solve the problem of waste stacking. For this reason, Chinese scholars put forward a mixed workface which combines one part of the goaf that is managed with a fully mechanized gangue backfilling method (FMGBM) while the other part is dealed with the traditional caving method (TCM). The FMGBM is used for one part of the mixed workface, and the TCM is used for another. The two methods work together to ensure the coal output of the mixed workface. For this kind of mixed workface, the length of the backfilling section, length must be determined and well designed to provide a basis for support equipment design selection and mining pressure management. In order to solve this problem, it was firstly analyzed that the mining technology of mixed workface and the ABAQUS is used to establish the numerical simulation for the length optimization of the backfilling section in the mixed workface. By analyzing the influence of backfilling section length on roof vertical stress (i.e., vertical stress at the bottom of immediate roof, which represents the vertical pressure of immediate roof on coal body, caving rock, or backfilled gangue) and coal wall failure depth in backfilling section, caving section, goaf central position, and abutment stress area of the mixed workface, it is concluded that when the backfilling section length is more than 120 m, the roof vertical stress and coal wall failure depth are relatively small. Considering the cost of backfilling hydraulic supports, the backfilling section length of gangue is finally eventually determined to be 120 m. Finally, the industrial test was carried out in Ji15-31010 mixed workface of **dingshan No. 12 Coal Mine. The roof vertical stress in 5-m front of the workface coincides with that of the numerical simulation, which verifies the rationality of the 120 m length of the gangue section.

Similar content being viewed by others

References

Bai QS, Tu SH (2016) Failure analysis of a large span longwall drift under water-rich roofs and its control techniques. Eng Fail Anal 67:15–32. https://doi.org/10.1016/j.engfailanal.2016.05.028

Bai M, Kendorski F, Roosendaal DV (1995) Chinese and North American high-extraction underground coal mining strata behaviour and water protection experience and guidelines. In: Proceedings of the 14th International Conference on Ground Control in Mining Mining Technology, 1995. pp 209–217

Bai Q-S, Tu S-H, Zhang X-G, Zhang C, Yuan Y (2013) Numerical modeling on brittle failure of coal wall in longwall face—a case study. Arab J Geosci 7:5067–5080. https://doi.org/10.1007/s12517-013-1181-1

Bai QS, Tu SH, Chen M, Zhang C (2016) Numerical modeling of coal wall spall in a longwall face. Int J Rock Mech Min Sci 88:242–253. https://doi.org/10.1016/j.ijrmms.2016.07.031

Bertuzzi R (2013) Discussion on 'Sari, M., An improved method of fitting experimental data to the Hoek-Brown failure criterion, Engineering Geology (2012)'. Eng Geol 152:213. https://doi.org/10.1016/j.enggeo.2012.07.013

Bertuzzi R, Douglas K, Mostyn G (2016) Improving the GSI Hoek-Brown criterion relationships. Int J Rock Mech Min Sci 89:185–199. https://doi.org/10.1016/j.ijrmms.2016.09.008

Cerik BC (2017) Damage assessment of marine grade aluminium alloy-plated structures due to air blast and explosive loads. Thin Wall Struct 110:123–132. https://doi.org/10.1016/j.tws.2016.10.021

Coggan J, Gao FQ, Stead D, Elmo D (2012) Numerical modelling of the effects of weak immediate roof lithology on coal mine roadway stability. Int J Coal Geol 90:100–109. https://doi.org/10.1016/j.coal.2011.11.003

Emad MZ (2017) Numerical modelling approach for mine backfill Sadhana-Academy. Proc Eng Sci 42:1595–1604. https://doi.org/10.1007/s12046-017-0702-0

Fang K, Zhang J-x, Zhang Q, Sun Q, Yin W, Zhou F (2016) Fully mechanised mixed mining technology involving solid backfilling and caving methods in longwall workface. Min Technol 125:205–211. https://doi.org/10.1080/14749009.2016.1139338

G SMD (1990) Mechanism of caving in longwall coal mining. In: Rock Mechanics Contributions and Challenges: Proceedings of the 31st US Symposium, Golden, Colorado. pp 161-168

Gao R, Yu B, **a H, Duan H (2017) Reduction of stress acting on a thick, deep coal seam by protective-seam. Energies 10:1209. https://doi.org/10.3390/en10081209

Gong P, Ma Z, Ni X, Zhang R (2017) Floor heave mechanism of gob-side entry retaining with fully-mechanized backfilling. Energies 10. https://doi.org/10.3390/en10122085

Jiang LS, Wang P, Zhang PP, Zheng PQ, Xu B (2017) Numerical analysis of the effects induced by normal faults and dip angles on rock bursts. Comptes Rendus Mecanique 345:690–705. https://doi.org/10.1016/j.crme.2017.06.009

** K, Cheng Y, Wang W, Liu H, Liu Z, Zhang H (2016) Evaluation of the remote lower protective seam mining for coal mine gas control: a typical case study from the Zhuxianzhuang Coal Mine, Huaibei Coalfield, China. J Nat Gas Sci Eng 33:44–55. https://doi.org/10.1016/j.jngse.2016.05.004

Ju MH, Li XH, Yao QL, Li DW, Chong ZH, Zhou J (2015) Numerical investigation into effect of rear barrier pillar on stress distribution around a longwall face. J Cent South Univ 22:4372–4384. https://doi.org/10.1007/s11771-015-2986-8

Kong S, Cheng Y, Ren T, Liu H (2014) A sequential approach to control gas for the extraction of multi-gassy coal seams from traditional gas well drainage to mining-induced stress relief. Appl Energy 131:67–78. https://doi.org/10.1016/j.apenergy.2014.06.015

Li M, Zhang J, Huang Y, Zhou N (2017) Effects of particle size of crushed gangue backfill materials on surface subsidence and its application under buildings. Environ Earth Sci 76. https://doi.org/10.1007/s12665-017-6931-z

Liu H, Liu H, Cheng Y (2014) The elimination of coal and gas outburst disasters by ultrathin protective seam drilling combined with stress-relief gas drainage in **nggong coalfield. J Nat Gas Sci Eng 21:837–844. https://doi.org/10.1016/j.jngse.2014.10.022

Marinos P, Marinos V, Hoek E (2007) Geological Strength Index (GSI). A characterization tool for assessing engineering properties for rock masses. Underground Works under Special Conditions

Shabanimashcool M, Li CC (2012) Numerical modelling of longwall mining and stability analysis of the gates in a coal mine. Int J Rock Mech Min Sci 51:24–34. https://doi.org/10.1016/j.ijrmms.2012.02.002

Sun Q, Zhang J, Zhang Q, Yan H (2018a) A case study of mining-induced impacts on the stability of multi-tunnels with the backfill mining method and controlling strategies. Environ Earth Sci 77. https://doi.org/10.1007/s12665-018-7414-6

Sun W, Wang H, Hou K (2018b) Control of waste rock-tailings paste backfill for active mining subsidence areas. J Clean Prod 171:567–579. https://doi.org/10.1016/j.jclepro.2017.09.253

Wang AL, Ma LQ, Wang ZW, Zhang DS, Li K, Zhang Y, Yi XJ (2016) Soil and water conservation in mining area based on ground surface subsidence control: development of a high-water swelling material and its application in backfilling mining. Environ Earth Sci 75:779. https://doi.org/10.1007/s12665-016-5577-6

Wang PF, Zhao JL, Chugh YP, Wang ZQ (2017) A novel longwall mining layout approach for extraction of deep coal deposits. Minerals 7:60. https://doi.org/10.3390/min7040060

**e J, Zhu W, Xu J, Wen J, Liu C (2015) A study on the bearing effect of pier column backfilling in the goaf of a thin coal seam. Geosci J 20:361–369. https://doi.org/10.1007/s12303-015-0047-9

Yang TH, Xu T, Liu HY, Tang CA, Shi BM, Yu QX (2011) Stress-damage-flow coupling model and its application to pressure relief coal bed methane in deep coal seam International. J Coal Geol 86:357–366. https://doi.org/10.1016/j.coal.2011.04.002

Yang S-Q, Chen M, **g H-W, Chen K-F, Meng B (2017) A case study on large deformation failure mechanism of deep soft rock roadway in **n'An coal mine, China. Eng Geol 217:89–101. https://doi.org/10.1016/j.enggeo.2016.12.012

Yilmaz T, Ercikdi B, Deveci H (2018) Utilisation of construction and demolition waste as cemented paste backfill material for underground mine openings. J Environ Manag 222:250–259. https://doi.org/10.1016/j.jenvman.2018.05.075

Zhang J-x, Huang P, Zhang Q, Li M, Chen Z-w (2017) Stability and control of room mining coal pillars—taking room mining coal pillars of solid backfill recovery as an example. J Cent South Univ 24:1121–1132. https://doi.org/10.1007/s11771-017-3515-8

Zhang GC, He FL, Jia HG, Lai YH (2017a) Analysis of gateroad stability in relation to yield pillar size: a case study rock. Mech Rock Eng 50:1263–1278. https://doi.org/10.1007/s00603-016-1155-1

Zhang J, Zhang Q, Spearing AJS, Miao X, Guo S, Sun Q (2017c) Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int J Min Sci Technol 27:17–27. https://doi.org/10.1016/j.ijmst.2016.11.014

Zhang X, Lin J, Liu J, Li F, Pang Z (2017d) Investigation of hydraulic-mechanical properties of paste backfill containing coal gangue-fly ash and its application in an underground coal mine. Energies 10. https://doi.org/10.3390/en10091309

Zhou XP, Li JL (2011) Hoek-Brown criterion applied to circular tunnel using elastoplasticity and in situ axial stress. Theor Appl Fract Mech 56:95–103. https://doi.org/10.1016/j.tafmec.2011.10.005

Acknowledgments

This work was supported by the fundamental research funds for the central universities (2019BSCX04). The authors gratefully acknowledge the financial support from the organization mentioned above.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tai, Y., Guo, S. & Lan, L. Reasonable gangue section length for disposing gangue pollutants in the new green mixed workface. Bull Eng Geol Environ 79, 1669–1682 (2020). https://doi.org/10.1007/s10064-019-01677-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-019-01677-x