Abstract

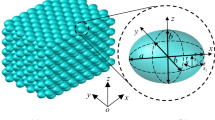

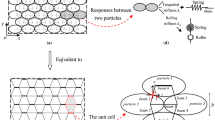

By the micro-structural mechanics approach, this study establishes the quantitative stress–strain relationships at the elastic stage with respect to the microscopic features of the particles for anisotropic granular materials that are composed of regularly arranged elliptical particles with the same size. Firstly, the elliptical particle assembly is equated with a lattice network described by beam elements attached to the center of particles. Then, the elastic stress–strain relationships, which exactly show the features of orthotropic micropolar continuum, are established through analyzing the triangular and hexagonal cells based on the principle of energy balance. Finally, the analytical expressions of eight independent parameters in stress–strain relationships are obtained as the functions of particle shape, size, and microscopic contact stiffnesses. Further, the relationship between microscopic parameters and macroscopic elastic constants for anisotropic granular materials is proposed. The analytical expressions are verified by comparison between theoretical and discrete element method (DEM) results for elliptical particle assembly, and the influences of microscopic parameters on the macroscopic elastic constants are investigated in detail according to the proposed analytical expressions. Our work provides some useful insights for the microscopic explanation and the influences of microscopic parameters on the macroscopic mechanical behavior of granular materials.

Graphic abstract

Similar content being viewed by others

Abbreviations

- \(a\), \(b\) :

-

The major and minor axes of ellipse

- \(e_{ijk}\) :

-

Permutation tensor

- \(E_{i} (i = 1,2)\) :

-

Elastic modulus along i direction

- \(f_{i}^{c}\) :

-

Contact force

- \(G\) :

-

Shear modulus

- \(K_{ij}^{c}\) :

-

Contact stiffness tensor

- \(l_{k}^{c}\) :

-

Length vector corresponding to the beam c in the triangle cell

- \(m\) :

-

Major-minor axis ratio of elliptical particles

- \(M_{i}^{c}\) :

-

Contact moment

- \(R_{E}\), \(R_{B}\) :

-

Elastic and bending modulus ratios, respectively

- \(R_{G}\) :

-

Shear modulus ratio

- \(T_{ij}^{c}\) :

-

Rotation stiffness tensor

- \(u_{i,k}^{o}\) :

-

Displacement gradient

- \(V\) :

-

The area of the unit cell

- α :

-

The angle between tangential direction and the x-axis at contact points A2 (A3)

- \(\beta\) :

-

Base angle of the isosceles triangle

- γ :

-

Contact anisotropy ratio

- \(\delta_{i}^{c}\) :

-

Relative displacement

- \(\varepsilon_{ki}^{o}\) :

-

Strain tensor

- \(\zeta\) :

-

Shape parameter

- \(\eta_{p}^{c}\) :

-

Position vector from centroid of the triangle cell to the contact point corresponding to the beam c

- \(\theta_{i}^{c}\) :

-

Relative rotation

- \(\kappa_{i} (i = 1,2)\) :

-

Bending modulus along i direction

- \(\lambda\) :

-

Tangential-normal contact stiffness ratio

- \(\mu_{pj}\) :

-

Couple stress tensor

- \(\nu_{ij} (i \ne j)\) :

-

Poisson’s ratio that deformation along j direction due to applied stress along i direction

- \(\xi\) :

-

Rolling-normal contact stiffness ratio

- \(\rho\) :

-

The local rigid rotation ratio

- \(\sigma_{mq}\) :

-

Cauchy stress tensor

- \(\omega_{j,p}^{o}\) :

-

Rotation gradient

References

Chang, C.S., Ma, L.: Modelling of discrete granulates as micropolar continuum. J. Eng. Mech. 116(12), 2703–2721 (1990)

Chang, C.S.: Estimates of elastic moduli for granular material with anisotropic random packing structure. Int. J. Solids Struct. 32(14), 1989–2008 (1995)

Chang, C.S., Wang, T.K., Sluys, L.J., Mier, J.G.M.V.: Fracture modeling using a micro-structural mechanics approach––I theory and formulation. Eng. Fract. Mech. 69(17), 1941–1958 (2002)

Griffiths, D.V., Mustoe, G.G.W.: Modelling of elastic continua using a grillage of structural elements based on discrete element concepts. Int. J. Numer. Methods Eng. 50(7), 1759–1775 (2001)

Tavarez, F.A., Plesha, M.E.: Discrete element method for modelling solid and particulate materials. Int. J. Numer. Methods Eng. 70(4), 379–404 (2007)

Liu, C., Pollard, D.D., Shi, B.: Analytical solutions and numerical tests of elastic and failure behaviors of close-packed lattice for brittle rocks and crystals. J. Geophys. Res. Solid Earth. 118(1), 71–82 (2013)

Liu, C., Xu, Q., Shi, B., Deng, S., Zhu, H.: Mechanical properties and energy conversion of 3d close-packed lattice model for brittle rocks. Comput. Geosci. 103, 12–20 (2017)

Wang, Y., Mora, P.: Macroscopic elastic properties of regular lattices. J. Mech. Phys. Solids 56(12), 3459–3474 (2008)

JoséMiranda, G., Kikuchi, N.: Preprocessing and postprocessing for materials based on the homogenization method with adaptive finite element methods. Comput. Meth. Appl. Mech. Eng. 83(2), 143–198 (1990)

Ghosh, S., Moorthy, S.: Elastic-plastic analysis of arbitrary heterogeneous materials with the voronoi Cell finite element method. Comput. Meth. Appl. Mech. Eng. 121(1–4), 373–409 (1995)

Costanzo, F., Boyd, J.G., Allen, D.H.: Micromechanics and homogenization of inelastic composite materials with growing cracks. J. Mech. Phys. Solids 44(3), 333–370 (1996)

Dvorak, G.J., Zhang, J.: Transformation field analysis of damage evolution in composite materials. J. Mech. Phys. Solids 49(11), 2517–2541 (2001)

Arthur, J.R.F., Menzies, B.K.: Inherent anisotropy in a sand. Géotechnique 22(1), 128–130 (1972)

Oda, M., Koishikawa, I., Higuchi, T.: Experimental study of anisotropic shear strength of sand by plane strain test. Soils Found. 18, 25–38 (1978)

Guo, P.: Modified direct shear test for anisotropic strength of sand. J. Geotech. Geoenviron. Eng. 134(9), 1311–1318 (2008)

Song, F., Zhang, J.M., Cao, G.R.: Experimental investigation of asymptotic state for anisotropic sand. Acta Geotech. 10(5), 571–585 (2015)

Rothenburg, L., Bathurst, R.J.: Numerical simulation of idealized granular assemblies with plane elliptical particles. Comput. Geotech. 11(4), 315–329 (1991)

Jiang, M.J., Liu, F., Zhou, Y.: A bond failure criterion for DEM simulations of cemented geomaterials considering variable bond thickness. Int. J. Numer. Anal. Methods Geomech 38(18), 1871–1897 (2014)

Hosseininia, E.S.: Investigating the micromechanical evolutions within inherently anisotropic granular materials using discrete element method. Granul. Matter 14(4), 483–503 (2012)

Jiang, M.J., Sima, J., Li, L., Zhou, C., Cui, L.: Investigation of influence of particle characteristics on the non-coaxiality of anisotropic granular materials using DEM. Int. J. Numer. Anal. Methods Geomech. 41(2), 198–222 (2017)

Jiang, M.J., Zhang, A., Fu, C.: 3-D DEM simulations of drained triaxial tests on inherently anisotropic granulates. Eur. J. Environ. Civ. Eng. 22(S1), 37–56 (2018)

Walton, K.: The effective elastic modulus of a random packing of spheres. J. Mech. Phys. Solids 35(2), 213–226 (1987)

Cosserat, E., Cosserat, F.: Theorie des corps Deformables. Hermann, Paries (1909)

Leonetti, L., Fantuzzi, N., Trovalusci, P., Tornabene, F.: Scale effects in orthotropic composite assemblies as micropolar continua: a Comparison between weak-and strong-form finite element solutions. Materials 12(5), 758 (2019)

Ng, T.T.: Numerical simulations of granular soil using elliptical particles. Comput. Geotech. 16(2), 153–169 (1994)

Zheng, Q.J., Zhou, Z.Y., Yu, A.B.: Contact forces between viscoelastic ellipsoidal particles. Powder Technol. 248, 25–33 (2013)

Lekhnitskii, S.G.: Theory of elasticity of an anisotropic body. Moscow: Mir (1981)

Eringen, A.C.: Theory of micropolar elasticity. In: Microcontinuum Field Theories. Springer, New York, NY (1999). https://doi.org/10.1007/978-1-4612-0555-5_5

Casolo, S.: Modelling in-plane micro-structure of masonry walls by rigid elements. Int. J. Solids Struct. 41(13), 3625–3641 (2004)

Casolo, S.: Macroscopic modelling of structured materials: relationship between orthotropic cosserat continuum and rigid elements. Int. J. Solids Struct. 43(3–4), 475–496 (2006)

Potyondy, D.O., Cundall, P.A.: A bonded-particle model for rock. Int. J. Rock Mech. Min. Sci. 41(8), 1329–1364 (2004)

Bathurst, R.J., Rothenburg, L.: Note on a random isotropic granular material with negative Poisson’s ratio. Int. J. Eng. Sci. 26(4), 373–383 (1988)

Wadee, M.K., Wadee, M.A., Bassom, A.P.: Effects of orthotropy and variation of Poisson’s ratio on the behaviour of tubes in pure flexure. J. Mech. Phys. Solids 55(5), 1086–1102 (2007)

Jiang, M.J., Yu, H.S., Harris, D.: A novel discrete model for granular material incorporating rolling resistance. Comput. Geotech. 32(5), 340–357 (2005)

Jiang, M.J., Yu, H.S., Harris, D.: Bond rolling resistance and its effect on yielding of bonded granulates by DEM analyses. Int. J. Numer. Anal. Methods Geomech. 30(8), 723–761 (2006)

Jiang, M.J., Zhu, H.H.: An interpretation of the internal length in chang’s couple-stress continuum for bonded granulates. Granul. Matter 9(6), 431–437 (2007)

Chang, C.S., Shi, Q.: Mix-mode elastic finite element formulation for bonded granular material considering rotation of particles. J. Eng. Mech. 131(2), 120–130 (2005)

Shen, Z.F., Jiang, M.J., Thornton, C.: DEM simulation of bonded granular material part I contact model and application to cemented sand. Comput. Geotech. 75(may), 192–209 (2016)

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant Nos. 11872281, 51639008, and 51890911), and the State Key Laboratory of Disaster Reduction in Civil Engineering (Grant No. SLDRCE19-A-06).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Z.H., Wang, H.N. & Jiang, M.J. Elastic constants obtained analytically from microscopic features for regularly arranged elliptical particle assembly. Granular Matter 23, 29 (2021). https://doi.org/10.1007/s10035-021-01088-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01088-4