Abstract

It is commonly accepted that the load-independent losses in high-speed gears can become prominent for peripheral speeds above 100 m/s. In this context, it has been shown that flanges and shrouds can mitigate these windage effects but no clear conclusions have been reached about the influence of radial and axial obstacles, especially for high-speeds. Moreover, the proposed solutions should be compatible with the casing design, including the possibility to properly lubricate and cool down the gears. In this paper, a specific test rig is used in order to investigate the power loss reductions when either one or two axial flanges are mounted close to the gears. It is shown that windage power losses are strongly reduced when flanges are very close to the gear faces. The influence of several parameters such as the number of flanges, the gear module and the gear geometry (i.e. spur or helical) is discussed. Finally, an approximate equation is proposed, which can be used to estimate WPL reductions at the design stage.

Zusammenfassung

Es ist allgemein anerkannt, dass die lastunabhängigen Verluste in Hochgeschwindigkeitsgetrieben bei Umfangsgeschwindigkeiten über 100 m/s deutlich werden können. In diesem Zusammenhang hat sich gezeigt, dass Flansche und Deckbänder diese Windwirkungseffekte abmildern können, jedoch wurden keine eindeutigen Aussagen über den Einfluss von radialen und axialen Hindernissen, insbesondere bei hohen Drehzahlen, getroffen. Darüber hinaus sollten die vorgeschlagenen Lösungen mit dem Gehäusedesign kompatibel sein, einschließlich der Möglichkeit, die Getriebe richtig zu schmieren und zu kühlen. In diesem Artikel wird ein spezieller Prüfstand verwendet, um die Verlustleistungsreduzierung zu untersuchen, wenn entweder ein oder zwei axiale Flansche in der Nähe der Zahnräder montiert werden. Es zeigt sich, dass die Seitenleistungsverluste stark reduziert werden, wenn die Flansche sehr nahe an den Zahnflanken liegen. Der Einfluss verschiedener Parameter wie der Anzahl der Flansche, des Verzahnungsmoduls und der Verzahnungsgeometrie (z. B. Stirnrad oder Schrägverzahnung) wird diskutiert. Schließlich wird eine Näherungsgleichung vorgeschlagen, die verwendet werden kann, um WPL-Reduktionen in der Entwurfsphase abzuschätzen.

Similar content being viewed by others

Notes

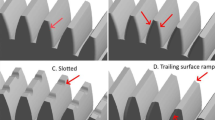

Two types of enclosures are defined: shrouds are radially positioned; flanges are axially placed with respect to the pinion.

References

Dawson PH (1984) Windage loss in larger high-speed gears. Proc Inst Mech Power Process Eng. https://doi.org/10.1243/PIME_PROC_1984_198_007_02

Johnson G, Simmons K, Foord C (2007) Experimetal investigation into windage power loss from a shrouded spiral bevel gear. In: Montréal: Proceedings of ASME Turbo Expo 2007: Power for Land, Sea and Air https://doi.org/10.1115/GT2007-27885

Simmons K, Johnson G, Wiedemann N (2011) Effect of pressure and oil mist on windage power loss of a shrouded bevel gear. In: Vancouver: Proceedings of ASME Turbo Exp https://doi.org/10.1115/GT2011-46426

Winfree DD (2000) Reducing gear windage losses from high speed gears. In: Baltimore: Proc ASME Power transmission and Gearing conference https://doi.org/10.1115/DETC2000/PTG-14449

Arisawa H, Nishimura M, Imai H, Goi T (2014) Computational fluid dynamics simulation and experiments for reduction of oil churning loss and windage loss in aeroengine tranmission gears. J Eng Gas Turbines Power. https://doi.org/10.1115/1.4026952

Diab Y, Ville F, Velex P, Changenet C (2004) Windage losses in hugh-speed gears—Preliminary experimental and theoretical results. ASME J Mech Des 126:903–908. https://doi.org/10.1115/1.1767815

Marchesse Y, Changenet C, Ville F, Velex P (2011) Investigation on CFD simulations for predicting windage power loss in spur gears. J Mech Des. https://doi.org/10.1115/1.4003357

Handschuh RF, Hurrell MJ (2010) Initial experiments of high-speed drive system windage losses. In: Garching, Germany: Internation conference on gears 2010

Hill MJ, Kunz J, Noack RF, Long W, Morris PJ, Handschuh RF (2008) Application and validation of unstructured overset CFD technology for rotorcraft gearbox windage aerodynamics simulation. In: Montreal : Proc. 64th American helicopter society annual forum

Al-Shibl K, Simmons H, Eastwick CN (2006) Modelling windage power loss from an enclosed spur gear. J Power Energy. https://doi.org/10.1243/09576509JPE344

Fondelli T, Andreini A, Bacchini B (2018) Numerical Investigation on Windage Losses of High-Speed Gears in Enclosed Configuration. AIAA J. https://doi.org/10.2514/1.J055871

Hill MJ, Kunz RF, Medvitz RB, Handschuh RF, Long LN, Noack RW (2011) CFD analysis of gear windage losses: validation and parametric aerodynamic studies. J Fluids Eng. https://doi.org/10.1115/1.4003681

Ruzek M, Ville F, Velex P, Boni JB, Marchesse Y (2019) On windage losses in high-speed pinion-gear pairs. Mech Mach Theory. https://doi.org/10.1016/j.mechmachtheory.2018.10.018

Pallas S, Marchesse Y, Changenet C, Ville F, Velex P (2013) Application and validation of a simplified numerical approach for the estimation of windage power losses in spur gears. Comput Fluids. https://doi.org/10.1016/j.compfluid.2013.04.025

Menter FR (1994) Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. https://doi.org/10.2514/3.12149

Voeltzel N, Marchesse Y, Changenet C, Ville F, Velex P (2016) On the influence of helix angle on gear windage losses. J Mech Eng Sci. https://doi.org/10.1177/0954406215602036

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Y. Marchesse, M. Ruzek, F. Ville and P. Velex declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Marchesse, Y., Ruzek, M., Ville, F. et al. On windage power loss reduction achieved by flanges. Forsch Ingenieurwes 86, 389–394 (2022). https://doi.org/10.1007/s10010-021-00569-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-021-00569-5