Abstract

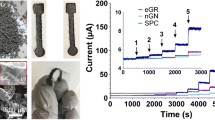

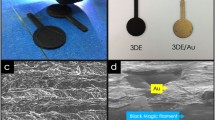

A new electrochemical device fabricated by the combination of 3D printing manufacturing and laser-generated graphene sensors is presented. Cell and electrodes were 3D printed by the fused deposition modeling (FDM) technique employing acrylonitrile butadiene styrene filament (insulating material that composes the cell) and conductive filament (lab-made filament based on graphite dispersed into polylactic acid matrix) to obtain reference and auxiliary electrodes. Infrared-laser engraved graphene, also reported as laser-induced graphene (LIG), was produced by laser conversion of a polyimide substrate, which was assembled in the 3D-printed electrochemical cell that enables the analysis of low volumes (50–2000 μL). XPS analysis revealed the formation of nitrogen-doped graphene multilayers that resulted in excellent electrochemical sensing properties toward the detection of atropine (ATR), a substance that was found in beverages to facilitate sexual assault and other criminal acts. Linear range between 5 and 35 μmol L−1, detection limit of 1 μmol L−1, and adequate precision (RSD = 4.7%, n = 10) were achieved using differential-pulse voltammetry. The method was successfully applied to beverage samples with recovery values ranging from 80 to 105%. Interference studies in the presence of species commonly found in beverages confirmed satisfactory selectivity for ATR sensing. The devices proposed are useful portable analytical tools for on-site applications in the forensic scenario.

Graphical Abstract

Similar content being viewed by others

References

Ngo TD, Kashani A, Imbalzano G et al (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Whittingham MJ, Crapnell RD, Rothwell EJ et al (2021) Additive manufacturing for electrochemical labs: an overview and tutorial note on the production of cells, electrodes and accessories. Talanta Open 4:100051. https://doi.org/10.1016/j.talo.2021.100051

Ambrosi A, Pumera M (2016) 3D-printing technologies for electrochemical applications. Chem Soc Rev 45:2740–2755. https://doi.org/10.1039/C5CS00714C

Cardoso RM, Kalinke C, Rocha RG et al (2020) Additive-manufactured (3D-printed) electrochemical sensors: a critical review. Anal Chim Acta 1118:73–91. https://doi.org/10.1016/j.aca.2020.03.028

Duarte LC, Baldo TA, Silva-Neto HA et al (2022) 3D printing of compact electrochemical cell for sequential analysis of steroid hormones. Sensors Actuators B Chem 364:131850. https://doi.org/10.1016/j.snb.2022.131850

Inoque NIG, João AF, de Faria LV, Muñoz RAA (2022) Electrochemical determination of several biofuel antioxidants in biodiesel and biokerosene using polylactic acid loaded with carbon black within 3D-printed devices. Microchim Acta 189:57. https://doi.org/10.1007/s00604-021-05152-x

João AF, Matias TA, Gomes JS et al (2021) An environmentally friendly three-dimensional printed graphene-integrated polylactic acid electrochemical sensor for the quality control of biofuels. ACS Sustain Chem Eng 9:16052–16062. https://doi.org/10.1021/acssuschemeng.1c03361

Rocha DP, Rocha RG, Castro SVF et al (2022) Posttreatment of 3D-printed surfaces for electrochemical applications: a critical review on proposed protocols. Electrochem Sci Adv 2:e2100136. https://doi.org/10.1002/elsa.202100136

Stefano JS, Kalinke C, da Rocha RG et al (2022) Electrochemical (Bio)Sensors enabled by fused deposition modeling-based 3D printing: a guide to selecting designs, printing parameters, and post-treatment protocols. Anal Chem 94:6417–6429. https://doi.org/10.1021/acs.analchem.1c05523

Ye R, James DK, Tour JM (2018) Laser-induced graphene. Acc Chem Res 51:1609–1620. https://doi.org/10.1021/acs.accounts.8b00084

Ye R, James DK, Tour JM (2019) Laser-induced graphene: from discovery to translation. Adv Mater 31:1803621. https://doi.org/10.1002/adma.201803621

Thamaraiselvan C, Wang J, James DK et al (2020) Laser-induced graphene and carbon nanotubes as conductive carbon-based materials in environmental technology. Mater Today 34:115–131. https://doi.org/10.1016/j.mattod.2019.08.014

Costa WRP, Rocha RG, de Faria LV et al (2022) Affordable equipment to fabricate laser-induced graphene electrodes for portable electrochemical sensing. Microchim Acta 189:185. https://doi.org/10.1007/s00604-022-05294-6

Matias TA, de Faria LV, Rocha RG et al (2022) Prussian blue-modified laser-induced graphene platforms for detection of hydrogen peroxide. Microchim Acta 189:188. https://doi.org/10.1007/s00604-022-05295-5

Matias TA, Rocha RG, Faria LV et al (2022) Infrared laser-induced graphene sensor for tyrosine detection. Chem Electro Chem. https://doi.org/10.1002/celc.202200339

Mendes LF, Pradela-Filho LA, Paixão TRLC (2022) Polyimide adhesive tapes as a versatile and disposable substrate to produce CO2 laser-induced carbon sensors for batch and microfluidic analysis. Microchem J 182:107893. https://doi.org/10.1016/j.microc.2022.107893

João AF, Rocha RG, Matias TA et al (2021) 3D-printing in forensic electrochemistry: atropine determination in beverages using an additively manufactured graphene-polylactic acid electrode. Microchem J 167:106324. https://doi.org/10.1016/j.microc.2021.106324

Crapnell RD, Banks CE (2021) Electroanalytical overview: the detection of the molecule of murder atropine. Talanta Open 4:100073. https://doi.org/10.1016/j.talo.2021.100073

Camargo JR, Fernandes-Junior WS, Azzi DC et al (2022) Development of new simple compositions of silver inks for the preparation of pseudo-reference electrodes. Biosensors 12:761. https://doi.org/10.3390/bios12090761

Stefano JS, Rocha RG et al (2022) New conductive filament ready-to-use for 3D-printing electrochemical (bio)sensors: towards the detection of SARS-CoV-2. Anal Chim Acta 1191:339372. https://doi.org/10.1016/j.aca.2021.339372

Pereira JFS, Rocha RG, Castro SVF et al (2021) Reactive oxygen plasma treatment of 3D-printed carbon electrodes towards high-performance electrochemical sensors. Sensors Actuators B Chem 347:130651. https://doi.org/10.1016/j.snb.2021.130651

Cardoso RM, Mendonça DMH, Silva WP et al (2018) 3D printing for electroanalysis: from multiuse electrochemical cells to sensors. Anal Chim Acta 1033:49–57. https://doi.org/10.1016/j.aca.2018.06.021

Richter EM, Rocha DP, Cardoso RM et al (2019) Complete additively manufactured (3D-printed) electrochemical sensing platform. Anal Chem 91:12844–12851. https://doi.org/10.1021/acs.analchem.9b02573

Paschoarelli MV, Kavai MS, de Lima LF, de Araujo WR (2023) Laser-scribing fabrication of a disposable electrochemical device for forensic detection of crime facilitating drugs in beverage samples. Talanta 255:124214. https://doi.org/10.1016/j.talanta.2022.124214

Louette P, Bodino F, Pireaux J-J (2005) Polyimide XPS reference core level and energy loss spectra. Surf Sci Spectra 12:121–126. https://doi.org/10.1116/11.20051101

Vaughan E, Larrigy C, Burke M et al (2020) Visible laser scribing fabrication of Porous graphitic carbon electrodes: morphologies, electrochemical properties, and applications as disposable sensor platforms. ACS Appl Electron Mater 2:3279–3288. https://doi.org/10.1021/acsaelm.0c00612

Imbrogno A, Islam J, Santillo C et al (2022) Laser-induced graphene supercapacitors by direct laser writing of cork natural substrates. ACS Appl Electron Mater 4:1541–1551. https://doi.org/10.1021/acsaelm.1c01202

Ferrari AC, Basko DM (2013) Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat Nanotechnol 8:235–246. https://doi.org/10.1038/nnano.2013.46

Lin J, Peng Z, Liu Y et al (2014) Laser-induced porous graphene films from commercial polymers. Nat Commun 5:5714. https://doi.org/10.1038/ncomms6714

Murray R, Burke M, Iacopino D, Quinn AJ (2021) Design of experiments and optimization of laser-induced graphene. ACS Omega 6:16736–16743. https://doi.org/10.1021/acsomega.1c00309

Eckmann A, Felten A, Mishchenko A et al (2012) Probing the nature of defects in graphene by Raman spectroscopy. Nano Lett 12:3925–3930. https://doi.org/10.1021/nl300901a

Dushna O, Dubenska L, Vojs M et al (2022) Highly sensitive determination of atropine in pharmaceuticals, biological fluids and beverage on planar electrochemical cell with working boron-doped diamond electrode. Electrochim Acta 432:141182. https://doi.org/10.1016/j.electacta.2022.141182

Mocak J, Bond AM, Mitchell S, Scollary G (1997) A statistical overview of standard (IUPAC and ACS) and new procedures for determining the limits of detection and quantification: application to voltammetric and strip** techniques (Technical Report). Pure Appl Chem 69:297–328. https://doi.org/10.1351/pac199769020297

Mane S, Narmawala R, Chatterjee S (2018) Selective recognition of atropine in biological fluids and leaves of Datura stramonium employing a carbon nanotube–chitosan film based biosensor. New J Chem 42:10852–10860. https://doi.org/10.1039/C8NJ01312H

Dar RA, Brahman PK, Tiwari S, Pitre KS (2012) Electrochemical determination of atropine at multi-wall carbon nanotube electrode based on the enhancement effect of sodium dodecyl benzene sulfonate. Colloids Surf B Biointer 91:10–17. https://doi.org/10.1016/j.colsurfb.2011.10.020

Soomro RA, Nafady A, Hallam KR et al (2016) Highly sensitive determination of atropine using cobalt oxide nanostructures: influence of functional groups on the signal sensitivity. Anal Chim Acta 948:30–39. https://doi.org/10.1016/j.aca.2016.11.015

Bagheri H, Arab SM, Khoshsafar H, Afkhami A (2015) A novel sensor for sensitive determination of atropine based on a Co3O4-reduced graphene oxide modified carbon paste electrode. New J Chem 39:3875–3881. https://doi.org/10.1039/C5NJ00133A

Ensafi AA, Nasr-Esfahani P, Heydari-Bafrooei E, Rezaei B (2015) Determination of atropine sulfate using a novel sensitive DNA–biosensor based on its interaction on a modified pencil graphite electrode. Talanta 131:149–155. https://doi.org/10.1016/j.talanta.2014.07.082

Ramdani O, Metters JP, Figueiredo-Filho LCS et al (2013) Forensic electrochemistry: sensing the molecule of murder atropine. Analyst 138:1053–1059. https://doi.org/10.1039/C2AN36450F

Silva AL, Salvador GMS, Castro SVF, Carvalho NMF, Munoz RAA (2021) A 3D printer guide for the development and application of electrochemical Cells and devices. Front Chem 9:684256. https://doi.org/10.3389/fchem.2021.684256

Inoque NIG, de Faria LV, Muñoz RAA (2022) Additive manufacturing towards the fabrication of greener electrochemical sensors for antioxidants. J Braz Chem Soc 33:753–761. https://doi.org/10.21577/0103-5053.20220025

Acknowledgement

The authors are grateful for the financial support provided by Brazilian funding agencies: National Council for Scientific and Technological Development–CNPq (163330/2020-4, 315838/2021-3, 409680/2021-4, 304119/2019-9); and Coordination for the Improvement of Higher Education Personnel–CAPES (Project SCBA 88887.472618/2019-00 and Finance Code 001), MCTI/CNPQ/CAPES/FAPS N° 16/2014–PROGRAMA INCTBio (465389/2014-7), Research Support Foundation of the State of Minas Gerais–FAPEMIG (Grants APQ-02391-22, RED-00042–16 and APQ-03141–18), Carlos Chagas Filho Foundation for Research Support in the State of Rio de Janeiro–FAPERJ (26/205.806/2022), and São Paulo Research Foundation–FAPESP (2007/08244-5, 2007/54829-5, 2017/18574-4, 2021/08409-1). The authors express their gratitude to Prof. Dr. João Flávio da Silveira Petruci for providing the atropine reagent, to the Multiuser laboratory at the Institute of Physics for Raman experiments (equipment provided by CAPES supported by the “Pró-Equipamentos” grant), and to the Multiuser Laboratories of the Universidade Federal de Uberlândia (RELAM-UFU) for providing the equipment and technical support for experiments involving electron microscopy (FAPEMIG grant APQ-02391-22).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing of interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

ESM 1

Figure S1. Picture of the cell and its components. (A) the upper and (B) bottom parts. (C) Screws. (D) Pseudo-reference (with gray tip) and auxiliary (black) electrodes. (E) Steel plate for working electrode support and (F) LIG electrodes. (G) Cell set up for the experiments. Figure S2. (A) Schematic representation showing the distance between the electrodes (reference and counter) and (B) the working electrode and the distance between the reference and counter electrodes. Figure S3. (A) CVs recorded on the LIG electrode in the presence 1 mmol L-1 ATR using scan rate ranging from 40 to 200 mV s-1 using 0.12 mol L–1 BR buffer (pH=11.0) as supporting electrolyte; (B) Linear adjustment between Log I and Log v, and (C) I vs. v1/2. Figure S4. Linear relationship obtained between peak potential and log v. Figure S5. Successive baseline-corrected DPV recordings for 20 μmol L–1 ATR at LIG electrode using 0.12 mol L–1 BR buffer (pH=11.0) as supporting electrolyte. DPV conditions: a= 80 mV, tm= 80 ms and ΔEs= 8 mV. Figure S6. Calibration plots obtained by standard addition for the determination of ATR in spiked beverage samples: energetic drink (A), beer (B), white wine (C) and whisky (D). DPV conditions: a= 80 mV, tm= 80 ms and ΔEs= 8 mV. (DOCX 5982 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Matias, T.A., Ramos, D.L.O., Faria, L.V. et al. 3D-printed electrochemical cells with laser engraving: develo** portable electroanalytical devices for forensic applications. Microchim Acta 190, 297 (2023). https://doi.org/10.1007/s00604-023-05872-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00604-023-05872-2