Abstract

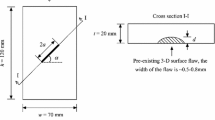

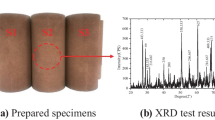

The confined tension region of a failure surface, where both tensile and compressive normal stresses are present, is experimentally challenging to investigate and consequently not fully characterized. In particular, strength tests of rock at stress states associated with low mean stress are rare. To address this limitation, axisymmetric extension experiments on dog-bone specimens are used in combination with axisymmetric extension and compression experiments on right-circular cylinders of Dunnville sandstone to define the confined tension region and evaluate linear (Mohr–Coulomb and Paul-Mohr–Coulomb) with tension cut-offs and non-linear (Hoek–Brown and Fairhurst) failure criteria. The strength tests indicate that a failure criterion that includes a tension cut-off best captures failure in the low mean stress regime, − T/3 < P < Co/3, where T = uniaxial tensile strength, P = mean stress, and Co = uniaxial compressive strength. Fracture surfaces of the dog-bone specimens were examined for failure mode based on surface roughness and it was found that there is a transition of decreasing roughness from tensile (opening) failure to hybrid (opening and sliding) failure to shear (sliding) failure.

Highlights

-

The simple failure criterion of tension cut-offs fits the confined-tensile testing results well.

-

The fracture surfaces examined using a 3D scanner showed that specimens tested under low mean stress exhibited higher surface roughness.

-

A transition of decreasing roughness from tensile (opening) failure to hybrid (opening and sliding) failure to shear (sliding) failure was observed.

Similar content being viewed by others

References

Asem P, Fuselier H, Labuz JF (2021) On a four-parameter linear failure criterion. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-021-02451-w

Bieniawski ZT (1967) Mechanism of brittle fracture of rock: Part I—theory of the fracture process. Int J Rock Mech Min Sci Geomech Abstr 4(4):395–404

Brace WF (1964) Brittle fracture of rocks. In: Judd WR (ed) State of stress in the earth’s crust. Elsevier, New York, pp 111–180

Brown ET (1981) Rock characterization, testing and monitoring: ISRM suggested methods. In: International Society for Rock Mechanics. Pergamon Press, Oxford

Christensen RM (1997) Yield functions/failure criteria for isotropic materials. Proc R Soc Lond A 453(1962):1473–1491

Corthésy R, Leite MH (2008) A strain-softening numerical model of core discing and damage. Int J Rock Mech Min Sci 45(3):329–350

Diederichs MS (2003) Rock fracture and collapse under low confinement conditions. Rock Mech Rock Eng 36:339–381

Fairhurst C (1964) On the validity of the Brazilian test for brittle materials. Int J Rock Mech Min Sci Geomech Abstr 1(4):535–546

Franklin JA, Hoek E (1970) Developments in triaxial testing technique. Rock Mech Rock Eng 2(4):223–228

Goodman RE (1989) Introduction to rock mechanics. Wiley, New York

Griffith AA (1924) Theory of rupture. In: Proceedings of the 1st Int. Cong. Appl. Mech., pp 55–63

Hagengruber T, Taha MR, Rougier E, Knight EE, Stormont JC (2021) Failure in confined Brazilian tests on sandstone. Appl Sci 11(5):2285. https://doi.org/10.3390/app11052285

Haimson BC, Cornet FH (2003) ISRM suggested methods for rock stress estimation—part 3: hydraulic fracturing (HF) and/or hydraulic testing of pre-existing fractures (HTPF). Int J Rock Mech Min Sci 40(7–8):1011–1020

Handin J (1969) On the Coulomb-Mohr failure criterion. J Geophys Res 74(22):5343–5348

Hoek E (1965) Rock fracture under static stress conditions. CSIR Report MEG 383, Pretoria, South Africa

Hoek E (1983) The strength of jointed rock masses. Géotechnique 33(3):187–223

Hoek E, Brown ET (1980) Empirical strength criterion for rock masses. J Geotech Eng Div ASCE 106(9):1013–1035

Hoek E, Martin CD (2014) Fracture initiation and propagation in intact rock—a review. J Rock Mech Geotech Eng 6(4):287–300

Jaeger JC (1966) Brittle fracture of rock. In: 8th U.S. Symposium on Rock Mechanics (USRMS), Minneapolis, Minnesota 3-57

Jaeger JC, Hoskins ER (1966) Rock failure under the confined Brazilian test. J Geophys Res 71(10):2651–2659

Labuz JF, Bridell JM (1993) Reducing frictional constraint in compression testing through lubrication. Int J Rock Mech Min Sci Geomech Abstr 30(4):451–455

Labuz JF, Zang A (2012) Mohr-Coulomb failure criterion. Rock Mech Rock Eng 45:975–979. https://doi.org/10.1007/s00603-012-0281-7

Labuz JF, Zeng F, Makhnenko RY, Li Y (2018) Brittle failure of rock: a review and general linear criterion. J Struct Geol 112:7–28

Lan H, Chen J, Macciotta R (2019) Universal confined tensile strength of intact rock. Sci Rep 9:6170. https://doi.org/10.1038/s41598-019-42698-6

Li Y, Ghassemi A (2018) Rock failure behavior and brittleness under confined Brazilian test. In: 52nd U.S. Rock Mechanics/Geomechanics Symposium; American Rock Mechanics Association: Seattle, WA, USA ARMA-2018-897

Lockner DA (1995) Rock failure. Am Geophys Union Ref Shelf Ser 3:127–147

Meyer JP, Labuz JF (2013) Linear failure criteria with three principal stresses. Int J Rock Mech Min Sci 60:180–187

Mogi K (1967) Effect of the intermediate principal stress on rock failure. J Geophys Res 72(20):5117–5131

Nadai A (1950) Theory of flow and fracture of solids (volume 1). McGraw-Hill, New York

Patel S, Martin CD (2018) Application of flattened Brazilian test to investigate rocks under confined extension. Rock Mech Rock Eng 51:3719–3736

Paul B (1961) A modification of the Coulomb-Mohr theory of fracture. J Appl Mech 28(2):259–268

Paul B (1968) Generalized pyramidal fracture and yield criteria. Int J Solids Struct 4(2):175–196

Perras MA, Diederichs MS (2014) A review of the tensile strength of rock: concepts and testing. Geotech Geol Eng 32:525–546

Ramsey JM, Chester MF (2004) Hybrid fracture and the transition from extension fracture to shear fracture. Nature 428:63–66

Sharpe JD (2017) Failure of rock at low mean stress. M.S. Thesis, University of Minnesota, Minneapolis, MN, USA

Tarokh A, Peng J, Fakhimi A, Labuz JF (2016) Evaluation of brittleness from spalling and bending tests. In: 50th U.S. Rock Mechanics/Geomechanics Symposium; American Rock Mechanics Association: Houston, TX, USA ARMA-2016-800

Tarokh A, Li Y, Labuz JF (2017) Hardening in porous chalk from precompaction. Acta Geotech 12:949–953

Tarokh A, Detournay E, Labuz JF (2018) Direct measurement of the unjacketed pore modulus of porous solids. Proc R Soc Lond A 474(2219):2018060

von Kármán T (1911) Festigkeitsversuche unter allseitigem druck. Z Ver Deutsch Ing 55(42):1749–1757

Wawersik WR, Fairhurst C (1970) A study of brittle rock fracture in laboratory compression experiments. Int J Rock Mech Min Sci Geomech Abstr 7(5):561–575

Yu M (2002) Advances in strength theories for materials under complex stress state in the 20th century. Appl Mech Rev 55(3):169–218

Zeng F, Folta BL, Labuz JF (2019) Strength testing of sandstone under multi-axial stress states. Geotech Geol Eng 37:4803–4814

Acknowledgements

This research was partially funded by the MSES/Miles Kersten Chair.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tarokh, A., Sharpe, J.D. & Labuz, J.F. Confined Tensile Testing of Porous Sandstone. Rock Mech Rock Eng 55, 6555–6566 (2022). https://doi.org/10.1007/s00603-022-03007-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-022-03007-2