Abstract

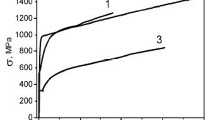

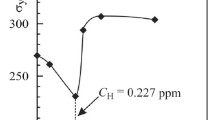

The non-destructive method of small mechanical stresses (at the beginning of the elastic region) is used to study the dependence of elastic hysteresis amplitudes ωh on time t during the release of diffused hydrogen from the samples. The samples used for the study correspond to the known model of a thin rigid round plate, pinched over the contour. The hydrogen diffusion coefficients D for studied samples are determined on the basis of the Fick equation solutions and the time t0 after which the ωh amplitudes do not longer change. It is shown that the D coefficient of 1020 steel does not change for all hydrogenation cycles of unstressed and stressed samples and corresponds to the following pattern, characteristic of low-alloy steels: the higher the carbon content, the lower the D coefficient is. Since the method used is non-destructive, high-precision and relatively simple, it can serve as a good addition to the known methods for determining the diffusion of hydrogen in metals. The reasons of significant decrease in the elastic hysteresis amplitudes ωh after the several cycles of hydrogenation of non-strained samples and a significant increase in ωh after hydrogenation of strained samples are also discussed.

Similar content being viewed by others

References

Park, C., Kang, N., Kim, M., Liu, S.: Effect of prestrain on hydrogen diffusion and trap** in structural steel. Mater. Lett. 235, 193–196 (2019). https://doi.org/10.1016/j.matlet.2018.10.049

Zhu, S., Zhang, C., Yang, Z., Wang, C.: Hydrogen’s influence on RAFM steels’ elastic properties: density functional theory combined with experiment. Nucl. Eng. Technol. 49, 1748–1751 (2017). https://doi.org/10.1016/j.net.2017.08.021

Swierczynska, A., Fydrych, D., Landowski, M., Rogalski, G., Łabanowski, J.: Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mat. 238, 117697 (2020). https://doi.org/10.1016/j.conbuildmat.2019.117697

Georges, C., Vanden Eynde, X.: Determination and study of diffusible hydrogen content in electro-galvanized steels by use of thermal desorption analysis. In: Proceedings of 8th international conference on zinc and zinc alloy coated steel sheet (Galvatech), 2011 June 21–24, Genova, Italy, (2011), p. 8

Carneiro Filho, C.J., Mansur, M.B., Modenesi, P.J., Gonzalez, B.M.: The effect of hydrogen release at room temperature on the ductility of steel wire rods for pre-stressed concrete. Mater. Sci. Eng. A 527, 4947–4952 (2010). https://doi.org/10.1016/j.msea.2010.04.042

Looney, C.P., Hagan, Z.M., Connolly, M.J., Bradley, P.E., Slifka, A.J., Amaro, R.L.: Modelling the test methods used to determine material compatibility for hydrogen pressure vessel service. Int. J. Fatigue 132, 105339 (2020). https://doi.org/10.1016/j.ijfatigue.2019.105339

Singh, V., Singh, R., Arora, K.S., Mahajan, D.K.: Hydrogen induced blister cracking failure in X65 pipeline steels. Int. J. Hydrogen Energy 44, 22039–22049 (2019). https://doi.org/10.1016/j.ijhydene.2019.06.098

Oudriss, A., Fleurentin, A., Courlit, G., Conforto, E., Berziou, C., Rébéré, C., Cohendoz, S., Sobrino, J.M., Creus, J., Feaugas, X.: Consequence of the diffusive hydrogen contents on tensile properties of martensitic steel during the desorption at room temperature. Mater. Sci. Eng. A 598, 420–428 (2014). https://doi.org/10.1016/j.msea.2014.01.039

Mytsyk, B., Ivanytsky, Y., Hembara, O., Kost, Y., Sakharuk, O.: Effects of hydrogen influence on strained steel 1020. Int. J. Hydrogen Energy 45, 10199–10208 (2020). https://doi.org/10.1016/j.ijhydene.2020.02.004

Katz, Y., Tymiak, N., Gerberich, W.W.: Nanomechanical probes as new approaches to hydrogen/deformation interaction studies. Eng. Fract. Mech. 68, 619–646 (2001)

Sun, Y., Chen, J., Liu, J.: Effect of hydrogen on ductility of high strength quenched and tempered (QT) Cr-Ni-Mo steels. Mater. Sci. Eng. A 625, 89–97 (2015). https://doi.org/10.1016/j.msea.2014.12.013

Liu, Y., Wang, M., Liu, G.: Effect of hydrogen on ductility of high strength 3Ni−Cr−Mo−V steels. Mater. Sci. Eng. A 594, 40–47 (2014). https://doi.org/10.1016/j.msea.2013.11.058

Djukic, M.B., Zeravcic, V.S., Bakic, G.M., Sedmak, A., Rajicic, B.: Hydrogen damage of steels: A case study and hydrogen embrittlement model. Eng. Fail. Anal. 58, 485–498 (2015). https://doi.org/10.1016/j.engfailanal.2015.05.017

Dmytrakh, I.M., Leshchak, R.L., Syrotyuk, A.M.: Effect of hydrogen concentration on strain behaviour of pipeline steel. Int. J. Hydrogen Energy 40, 4011–4018 (2015). https://doi.org/10.1016/j.ijhydene.2015.01.094

Martínez-Paňeda, E., Golahmar, A., Niordson, C.F.: A phase field formulation for hydrogen assisted cracking. Comp. Methods Appl. Mech. Eng. 342, 742–761 (2018). https://doi.org/10.1016/j.cma.2018.07.021

Wang, M.Q., Akiyama, E., Tsuzaki, K.: Hydrogen degradation of a boron-bearing steel with 1050 and 1300 MPa strength levels. Scripta Mater. 52, 403–408 (2005). https://doi.org/10.1016/j.scriptamat.2004.10.023

Yihong, N., Yuuji, K., Tadanobu, I., Fuxing, Y., Eiji, A., Kaneaki, T.: Hydrogen embrittlement of a 1500-MPa tensile strength level steel with an ultrafine elongated grain structure. Metal. Mater. Trans. A 43, 1670–1687 (2012). https://doi.org/10.1007/s11661-011-0974-7

Djukic, M.B., Bakic, G.M., Zeravcic, V.S., Sedmak, A., Rajicic, B.: The synergistic action and interplay of hydrogen embrittlement mechanismsin steels and iron: localized plasticity and decohesion. Eng. Fract. Mech. 216, 106528 (2019). https://doi.org/10.1016/j.engfracmech.2019.106528

Lin, M., Yu, H., Ding, Y., Wang, G., Olden, V., Alvaro, A., He, J., Zhang, Z.: A predictive model unifying hydrogen enhanced plasticity and decohesion. Scripta Mater. 215, 114707 (2022). https://doi.org/10.1016/j.scriptamat.2022.114707

Wasim, M., Djukic, M.B., Ngo, T.D.: Influence of hydrogen-enhanced plasticity and decohesion mechanisms of hydrogen embrittlement on the fracture resistance of steel. Eng. Fail. Anal. 123, 105312 (2021). https://doi.org/10.1016/j.engfailanal.2021.105312

Djukic, M.B., Bakic, G.M., Zeravcic, V.S., Sedmak, A., Rajicic, B.: Hydrogen embrittlement of industrial components: Prediction, prevention, and models. Corrosion 72, 943–961 (2016). https://doi.org/10.5006/1958

Lunarska, E., Ososkov, Y., Jagodzinsky, Y.: Correlation between critical hydrogen concentration and hydrogen damage of pipeline steel. Int. J. Hydrogen Energy 22, 279–284 (1997). https://doi.org/10.1016/S0360-3199(96)00178-4

Lufrano, J., Sofronis, P.: Enhanced hydrogen concentration ahead of rounded notches and cracks-competition between plastic strain and hydrostatic stress. Acta Mater. 46, 1519–1526 (1998). https://doi.org/10.1016/S1359-6454(97)00364-9

Dmytrakh, I.M., Leshchak, R.L., Syrotyuk, A.M., Barna, R.A.: Effect of hydrogen concentration on fatigue crack growth behaviour in pipeline steel. Int. J. Hydrogen Energy 42, 6401–6408 (2017). https://doi.org/10.1016/j.ijhydene.2016.11.193

Díaz, A., Cuesta, I.I., Martínez-Pañeda, E., Alegre, J.M.: Influence of charging conditions on simulated temperature-programmed desorption for hydrogen in metals. Int. J. Hydrogen Energy 45, 23704–23720 (2020). https://doi.org/10.1016/j.ijhydene.2020.05.192

Luo, H., Li, Z., Raabe, D.: Hydrogen enhances strength and ductility of an equiatomic high-entropy alloy. Sci. Rep. 7, 9892 (2017). https://doi.org/10.1038/s41598-017-10774-4

Alvaro, A., Jensen, I.T., Kheradmand, N., Lovvik, O.M., Olden, V.: Hydrogen embrittlement in nickel, visited by first principles modeling, cohesive zone simulation and nanomechanical testing. Int. J. Hydrogen Energy 40, 16892–16900 (2015). https://doi.org/10.1016/j.ijhydene.2015.06.069

Mytsyk, B.G., Ivanytskyi, Y.L., Balitskii, A.I., Kost, Y.P., Sakharuk, O.M.: Study of hydrogen influence on 1020 steel by low deformation method. Mater. Lett. 184, 328–331 (2016).https://doi.org/10.1016/j.matlet.2016.08.065

Mytsyk, B.G., Kost, Y.P., Demyanyshyn, N.M.: Effect of heat treatment of the D16 alloy on its mechanical properties at low stresses. Phys. Sol. State 56, 2227–2232 (2014). https://doi.org/10.1134/S1063783414110213

Kühne, D., Spak, B., Kästner, M., Brosius, A., Fiedler, M.: Consideration of cyclic hardening and residual stresses in fatigue life calculations with the local strain approach. Arch. Appl. Mech. 91, 3693–3707 (2021). https://doi.org/10.1007/s00419-021-01950-0

Sofianos, C.D., Koumousis, V.K.: Hysteretic beam element with degrading smooth models. Arch. Appl. Mech. 88, 253–269 (2018). https://doi.org/10.1007/s00419-017-1263-8

**, X., Le, Xu., Wenchao, Yu., Yao, K., Shi, J., Wang, M.: The effect of undissolved and temper-induced (Ti, Mo) C precipitates on hydrogen embrittlement of quenched and tempered Cr-Mo steel. Corrosion Sci. 166, 108421 (2020). https://doi.org/10.1016/j.corsci.2019.108421

Lin, Y.-C., Chen, D., Chiang, M.-H., Cheng, G.-J., Lin, H.-C., Yen, H.-W.: Response of hydrogen desorption and hydrogen embrittlement to precipitation of nanometer-sized copper in tempered martensitic low-carbon steel. JOM 71, 1349–1356 (2019). https://doi.org/10.1007/s11837-019-03330-0

Enomoto, M., Hirakami, D., Tarui, T.: Thermal desorption analysis of hydrogen in high strength martensitic steels. Metallurg. Mater. Transact. A 43, 572–581 (2012). https://doi.org/10.1007/s11661-011-0909-3

Lasseigne, A.N., McColskey, J.D., Siewert, T.A., Koenig, K., Jackson, J.E., Olson, D.L., Mishra, B.: Non-destructive determination of the diffusion coefficient of hydrogen in steel. In: Somerday B., Sofronis P., Russell H.J., (eds). Proceedings of the 2008 international hydrogen conference – effects of hydrogen on materials; 2008 september 7–10; Wyoming, USA. ASM International, 2009, 524–531. Doi: https://doi.org/10.3139/146.101729

Pérez Escobar, D., Verbeken, K., Duprez, L., Verhaege, M.: On the methodology of thermal desorption spectroscopy to evaluate hydrogen embrittlement. Mater. Sci. Forum 706–709, 2354–2359 (2012). https://doi.org/10.4028/www.scientific.net/MSF.706-709.2354

Mehrer, H.: Diffusionin in solids. Springer, Germany (2007). https://doi.org/10.1007/978-3-540-71488-0

Kronshtal, O.V., Kharin, V.S.: Effect of heterogeneity of materials and heat cycles on diffusion of hydrogen as a factor of the riskof development of hydrogen degradation of metals. Sov. Mater. Sci. 28, 475–486 (1992). https://doi.org/10.1007/BF00724456

Sandia Hydrogen Program. Technical reference for hydrogen compatibility of materials. 2013. http://www.sandia.gov/ matlsTechRef/. [Accessed 21 March 2019]

Laureys, A., Van den Eeckhout, E., Petrov, R.: Verbeken, K: Effect of deformation and charging conditions on crack and blister formation during electrochemical hydrogen charging. Acta Mater. 127, 192–202 (2017). https://doi.org/10.1016/j.actamat.2017.01.013

Li, X., Ma, X., Zhang, J., Akiyama, E., Wang, Y., Song, X.: Review of hydrogen embrittlement in metals: Hydrogen diffusion, hydrogen characterization, hydrogen embrittlement mechanism and prevention. Acta Metallurg. Sinica (English Letters) 33(6), 759–773 (2020). https://doi.org/10.1007/s40195-020-01039-7

Ramunni, V.P., De Paiva Coelho, T., De Miranda, P.E.V.: Interaction of hydrogen with the microstructure of low-carbon steel. Mater. Sci. Eng. A 435(10), 504–514 (2006). https://doi.org/10.1016/j.msea.2006.07.089

Laureys, A., Claeys, L., De Seranno, T., Depover, T., Van den Eeckhout, E., Petrov, R., Verbeken, K.: The role of titanium and vanadium based precipitates on hydrogen induced degradation of ferritic materials. Mater. Charact. 144, 22–34 (2018). https://doi.org/10.1016/j.matchar.2018.06.030

Wang, Z., Liu, J., Huang, F., Bi, Y.-J., Zhang, S.-q: Hydrogen diffusion and its effect on hydrogen embrittlement in DP steelswith different martensite content. Front. Mater. 7, 620000 (2020). https://doi.org/10.3389/fmats.2020.620000

Pérez Escobar, D., Depover, T., Duprez, L., Verbeken, K., Verhaege, M.: Combined thermal desorption spectroscopy, differential scanning calorimetry, scanning electron microscopy and X-ray diffraction study of hydrogen trap** in cold deformed TRIP steel. Acta Mater. 60, 2593–2605 (2012). https://doi.org/10.1016/j.actamat.2012.01.026

Acknowledgements

This work was financially supported by the National Research Foundation of Ukraine (Grant Numbers 2020.02/0049).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mytsyk, B., Hembara, O. & Shchepanskyi, P. Determination of hydrogen diffusion coefficients in metals by the method of low mechanical stresses. Arch Appl Mech 92, 3203–3213 (2022). https://doi.org/10.1007/s00419-022-02231-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-022-02231-0