Abstract

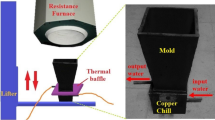

Finite element method was employed to calculate the macroflow velocity and temperature distribution of the pool domain’s biting zone in twin-roll casting. Macroanalysis results were inducted as boundary conditions into microanalysis. Phase field method (PFM) was adopted to investigate the microstructure evolution. Based on the Kim–Kim–Suzuki model, the effect of metal flow velocity was coupled on the solute gradient item, and the real physical parameters of AZ31 were inducted into the numerical calculation. We used the marker and cell method in the discrete element solution of microstructural pattern prediction of AZ31 magnesium alloys. The different flow velocity values that predicted the columnar dendrite evolution were discussed in detail. Numerical simulation results were also compared with the experiment analysis. The microstructure obtained by PFM agrees with the actual pattern observed via optical microscopy.

Similar content being viewed by others

References

K. Shibuya, M. Ozawa, Strip casting techniques for steel. ISIJ Int. 31, 661–668 (1991)

Y. Fujita et al., Solidification and roll-bonding of shells in twin-roll casting process. ISIJ Int. 29, 495–502 (1989)

M. Gupta, Y. Sahai, Mathematical modeling of fluid flow, heat transfer, and solidification in two-roll drag thin strip casting of steel. ISIJ Int. 40, 144–152 (2000)

D.J. Phelan et al., Experimental studies into strip casting of steel. Mater. Sci. Forum 539–543, 4155–4160 (2007)

H. Girgensohn, A.R. Buchner et al., Twin roll strip casting of low carbon steels. Ironmaking Steelmaking 27, 317 (2000)

T. Haga et al., Semisolid strip casting using a vertical type twin roll caster. Mater. Sci. Forum 426–432, 477–482 (2003)

T. Haga et al., High speed roll casting of aluminum alloy strip. Mater. Sci. Forum 475–479, 343–349 (2005)

T. Mizoguc et al., Relation between surface quality of as-cast strips and meniscus profile of molten pool in the twin roll casting process. ISIJ Int. 36, 417–423 (1996)

L. Strezov, J. Herbertson, Experimental studies of interfacial heat transfer and initial solidification pertinent to strip casting. ISIJ Int. 38, 959–966 (1998)

X.D. Hu, D.Y. Ju, H.Y. Zhao, Thermal flow simulation and concave type slot nozzle design for twin roll casting of magnesium alloy Az31. Mater. Sci. Forum 539–543, 5037–5042 (2007)

B.Q. Zhu, H. Chen, M. Militzer, Phase-field modeling of cyclic phase transformations in low-carbon steels. Comput. Mater. Sci. 108, 333–341 (2015)

H. **ng, X.L. Dong, C.L. Chen, J.Y. Wang, L.F. Du, K.X. **, Phase-field simulation of titled growth of dendritic arrays during directional solidification. Int. J. Heat Mass Transf. 90, 911–921 (2015)

R. Kobayashi, Modeling and numerical simulations of dendritic crystal growth. Physica D 63, 410–423 (1993)

A.A. Wheeler, B.T. Murrary, R.J. Schaefer, Computation of dendrites using a phase field model. Physica D 66, 243–262 (1993)

A.A. Wheeler, W.J. Boettinger, G.B. McFadden, Phase-field model for isothermal phase transitions in binary alloys. Phys. Rev. A 45, 7424–7439 (1992)

S.G. Kim, W.T. Kim, T. Suzuki, Phase-field model for binary alloys. Phys. Rev. E 60, 7186–7197 (1999)

M. Chen, X.D. Hu, D.Y. Ju, H.Y. Zhao, The microstructure prediction of magnesium alloy crystal growth in directional solidification. Comput. Mater. Sci. 79, 684–690 (2013)

F.H. Harlow, J.E. Welch, Numerical calculation of time-dependent viscous incompressible flow of fluid with free surface. Phys. Fluids 8(12), 2182–2189 (1965)

W. Kurz, D.J. Fisher, Fundamentals of solidification (Trans Tech Publications Ltd, Enfield, 1998)

J.S. Langer, Instabilities and pattern formation in crystal growth. Rev. Mod. Phys. 52, 21–28 (1980)

Acknowledgments

This research was financially supported by the LNIRT (LT2015014) and the Talent Fund of University of Science and Technology Liaoning (2013RC04). The authors wish to thank the help given by the Roll casting Research Center of Magnesium Alloy in University of Science and Technology Liaoning.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, M., Hu, XD., Han, B. et al. Study on the microstructural evolution of AZ31 magnesium alloy in a vertical twin-roll casting process. Appl. Phys. A 122, 91 (2016). https://doi.org/10.1007/s00339-016-9627-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-9627-4