Abstract

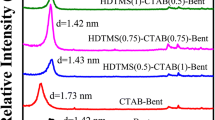

The current study investigates the production of organoclay suitable for use in the base section of a passenger tire with a cap/base tread construction. The process involved the purification and modification of two types of sodium bentonite clay with different mineral characteristics and ion exchange capacities using a single-step process. The modification process of purified bentonite suspensions was performed using a two-tailed long-chain alkyl quaternary ammonium salt surfactant, namely di (hydrogenated tallow alkyl) dimethyl ammonium chloride (AD2HT), and two one-tailed long-chain alkyl quaternary ammonium salt surfactants, namely cetyl-trimethylammonium chloride (CTAC) and octadecylamine chloride (ODA), in relatively low amounts of surfactant (0.95 CEC), along with polyethylene glycol (4% clay) as an auxiliary modifier. X-ray diffraction (XRD) showed that the interlayer spacing of organoclays significantly increases. In addition, the XRD pattern depends on the kind of surfactant and is independent of the type of bentonite clay. The resulting organoclays were added to the tread base section of a passenger tire using the melt masterbatch technique along with a silane coupling agent. An increase in curing maximum torque (8–15%), curing delta torque (6–14%), hardness (2–10%), static modulus 300 (2–18%), and dynamic storage modulus (11–30%) of the rubber composites was observed without significant change of resilience and loss factor of the composite at 2 Phr of organoclay loadings. The organoclays based on the AD2HT modifier exhibited better mechanical properties than those based on the ODA and CTAC surfactants. The dynamic storage modulus of composites increased by about 30% with only 2 Phr of AD2HT-modified bentonites. Furthermore, the performance of the organoclay was found to be independent of the primary particle size, iron content, and ion exchange capacity of the bentonite clay within the studied range.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

de Paiva LB, Morales AR, Valenzuela Díaz FR (2008) Organoclays: properties, preparation and applications. Appl Clay Sci 42:8–24. https://doi.org/10.1016/j.clay.2008.02.006

Mohanty S, Nayak SK, Kaith BS, Kalia S (2015) Polymer nanocomposites based on inorganic and organic nanomaterials. Wiley, Hoboken

George SC, Rajan R, Aprem AS et al (2016) The fabrication and properties of natural rubber-clay nanocomposites. Polym Test 51:165–173. https://doi.org/10.1016/j.polymertesting.2016.03.010

Archibong FN, Orakwe LC, Ogah OA et al (2023) Emerging progress in montmorillonite rubber/polymer nanocomposites: a review. J Mater Sci 58:2396–2429. https://doi.org/10.1007/s10853-023-08173-4

Ciftci H (2021) An introduction to montmorillonite purification. In: montmorillonite clay. IntechOpen, London

Kaufhold S, Dohrmann R, Ufer K, Meyer F (2002) Comparison of methods for the quantification of montmorillonite in bentonites. Appl Clay Sci 22:145–151. https://doi.org/10.1016/S0169-1317(02)00131-X

Thuc C-NH, Grillet A-C, Reinert L et al (2010) Separation and purification of montmorillonite and polyethylene oxide modified montmorillonite from Vietnamese bentonites. Appl Clay Sci 49:229–238. https://doi.org/10.1016/j.clay.2010.05.011

Stul MS, Van Leemput L (1982) Particle-size distribution, cation exchange capacity and charge density of deferrated montmorillonites. Clay Miner 17:209–216. https://doi.org/10.1180/claymin.1982.017.2.06

Carrado KA, Decarreau A, Petit S et al (2006) Chapter 4 synthetic clay minerals and purification of natural clays. Handbook of clay science. Elsevier, Amsterdam, pp 115–139

Katschnig M, Battisti M (2015) Processing of polymer–nanoclay composites. Polymer nanoclay composites. Elsevier, Amsterdam, pp 53–91

Barakan S, Aghazadeh V (2019) Separation and characterisation of montmorillonite from a low-grade natural bentonite: using a non-destructive method. Micro Nano Lett 14:688–693. https://doi.org/10.1049/mnl.2018.5364

Lee SY, Kim SJ (2002) Expansion of smectite by hexadecyltrimethylammonium. Clays Clay Miner 50:435–445. https://doi.org/10.1346/000986002320514163

Patel HA, Somani RS, Bajaj HC, Jasra RV (2010) Synthesis of organoclays with controlled particle size and whiteness from chemically treated Indian bentonite. Ind Eng Chem Res 49:1677–1683. https://doi.org/10.1021/ie801368b

Sadek EM, El-Nashar DE, Ahmed SM (2018) Influence of modifying agents of organoclay on the properties of nanocomposites based on acrylonitrile butadiene rubber. Egypt J Pet 27:1177–1185. https://doi.org/10.1016/j.ejpe.2018.04.007

Ishida H, Campbell S, Blackwell J (2000) General approach to nanocomposite preparation. Chem Mater 12:1260–1267. https://doi.org/10.1021/cm990479y

Choi J, Shin WS (2020) Removal of salicylic and ibuprofen by hexadecyltrimethylammonium-modified montmorillonite and zeolite. Minerals 10:898. https://doi.org/10.3390/min10100898

Thomas S, Stephen R (2010) Rubber nanocomposites. Wiley, Hoboken

Teh PL, Mohd Ishak ZA, Hashim AS et al (2004) On the potential of organoclay with respect to conventional fillers (carbon black, silica) for epoxidized natural rubber compatibilized natural rubber vulcanizates. J Appl Polym Sci 94:2438–2445. https://doi.org/10.1002/app.21188

Arroyo M, López-Manchado M, Herrero B (2003) Organo-montmorillonite as substitute of carbon black in natural rubber compounds. Polymer (Guildf) 44:2447–2453. https://doi.org/10.1016/S0032-3861(03)00090-9

Boczkowska A (2012) Advanced elastomers—technology, properties and applications. IntechOpen, London

Bao Z, Flanigan C, Beyer L, Tao J (2015) Processing optimization of latex-compounded montmorillonite/styrene-butadiene rubber–polybutadiene rubber. J Appl Polym Sci. https://doi.org/10.1002/app.41521

Bhadran B, Vijayan D, George N et al (2018) Reinforcing effect of organoclay in nitrile rubber-Effect of mill mixing and latex stage mixing. Appl Clay Sci 165:91–102. https://doi.org/10.1016/j.clay.2018.07.027

Meera AP, Thomas PS, Thomas S (2012) Effect of organoclay on the gas barrier properties of natural rubber nanocomposites. Polym Compos 33:524–531. https://doi.org/10.1002/pc.22188

Maria HJ, Thomas MG, Morreale M et al (2020) Gas barrier, rheological and mechanical properties of immiscible natural rubber/acrylonitrile butadiene rubber/organoclay (NR/NBR/organoclay) blend nanocomposites. Mater (Basel) 13(11):2654. https://doi.org/10.3390/ma13112654

Kim W-S, Lee D-H, Kim I-J et al (2009) SBR/organoclay nanocomposites for the application on tire tread compounds. Macromol Res 17:776–784. https://doi.org/10.1007/BF03218614

Sattayanurak S, Sahakaro K, Kaewsakul W, Dierkes WK, Reuvekamp LAEM, Blume A, & Noordermeer JWM (2019) Utilization of organoclay as secondary filler in silica-reinforced natural rubber tire tread compounds. Pap present fall 196th tech meet rubber div ACS 2019, Cleveland, United States 28

Bhattacharya M, Biswas S, Bhowmick AK (2011) Permeation characteristics and modeling of barrier properties of multifunctional rubber nanocomposites. Polymer (Guildf) 52:1562–1576. https://doi.org/10.1016/j.polymer.2011.01.055

Córdova WR, Julve D, Martínez M et al (2021) Effects of additives of organically modified montmorillonite and octosilicate in a silica reinforced tire tread mixture. Appl Clay Sci 200:105938. https://doi.org/10.1016/j.clay.2020.105938

Das A, Jurk R, Werner Stöckelhuber K et al (2008) Nanoalloy based on clays: intercalated-exfoliated layered silicate in high performance elastomer. J Macromol Sci Part A 45:144–150. https://doi.org/10.1080/10601320701786935

Ayippadath Gopi J, Patel SK, Chandra AK, Tripathy DK (2011) SBR-clay-carbon black hybrid nanocomposites for tire tread application. J Polym Res 18:1625–1634. https://doi.org/10.1007/s10965-011-9567-9

Das A, Stöckelhuber KW, Wang DY, Heinrich DG (2010) Synergistic effects of expanded nanoclay and carbon black on natural rubber compounds. Kautsch Gummi Kunstst 63:296–302

Masanori Kan A, Okazaki T, Sakashita T (1984) Tire Tread having low rolling resistance. U.S. Patent No. 4,444,236. Washington, DC: U.S. Patent and Trademark Office

Amaddeo A, Isola M, Serra A (2003) Low rolling resistance tire for vehicles having a composite tread. In: U.S. Patent No. 6,516,847. Washington, DC: U.S. Patent and Trademark Office

Sandstrom PH, Goldstein AA (2016) Tire with tread having base layer comprised of diverse zoned rubber compositions. In: U.S. Patent No. 9487050 B2. Goodyear Tire&Rubber Co., Akron, OH (US)

Suzuki S (2023) Rubber composition for base tread and tire. In: U.S. Patent No. US 2023/0072567 A1. Bridgestone Corporation

Shiva M, Akhtari SS, Shayesteh M (2020) Effect of mineral fillers on physico-mechanical properties and heat conductivity of carbon black-filled SBR/butadiene rubber composite. Iran Polym J 29:957–974. https://doi.org/10.1007/s13726-020-00854-0

Balachandran M, Bhagawan SS (2012) Mechanical, thermal and transport properties of nitrile rubber (NBR)—nanoclay composites. J Polym Res 19:9809. https://doi.org/10.1007/s10965-011-9809-x

Tan J, Wang X, Luo Y, Jia D (2012) Rubber/clay nanocomposites by combined latex compounding and melt mixing: a masterbatch process. Mater Des 34:825–831. https://doi.org/10.1016/j.matdes.2011.07.015

Sookyung U, Nakason C, Thaijaroen W, Vennemann N (2014) Influence of modifying agents of organoclay on properties of nanocomposites based on natural rubber. Polym Test 33:48–56. https://doi.org/10.1016/j.polymertesting.2013.11.006

Zhu S, Chen J, Li H, Cao Y (2013) Structure and conformation of poly(ethylene glycol) in confined space of montmorillonite. Appl Surf Sci 264:500–506. https://doi.org/10.1016/j.apsusc.2012.10.052

Carretero-González J, Valentín JL, Arroyo M et al (2008) Natural rubber/clay nanocomposites: Influence of poly(ethylene glycol) on the silicate dispersion and local chain order of rubber network. Eur Polym J 44:3493–3500. https://doi.org/10.1016/j.eurpolymj.2008.08.046

Chaiko DJ (2004) Process for preparation of organoclays. In: U.S. Patent No. US6521678B1. Argonne National Laboratory UChicago Argonne LLC

He H, Frost RL, Bostrom T et al (2006) Changes in the morphology of organoclays with HDTMA+ surfactant loading. Appl Clay Sci 31:262–271. https://doi.org/10.1016/j.clay.2005.10.011

Zhou Q, Frost RL, He H, ** Y (2007) Changes in the surfaces of adsorbed para-nitrophenol on HDTMA organoclay—The XRD and TG study. J Colloid Interface Sci 307:50–55. https://doi.org/10.1016/j.jcis.2006.11.016

Lee JY, Lee HK (2004) Characterization of organobentonite used for polymer nanocomposites. Mater Chem Phys 85:410–415. https://doi.org/10.1016/j.matchemphys.2004.01.032

García-López D, Gobernado-Mitre I, Fernández JF et al (2005) Influence of clay modification process in PA6-layered silicate nanocomposite properties. Polymer (Guildf) 46:2758–2765. https://doi.org/10.1016/j.polymer.2005.01.038

Malas A, Das CK (2013) Selective dispersion of different organoclays in styrene butadiene rubber in the presence of a compatibilizer. Mater Des 49:857–865. https://doi.org/10.1016/j.matdes.2013.02.040

Mohan TP, Kuriakose J, Kanny K (2011) Effect of nanoclay reinforcement on structure, thermal and mechanical properties of natural rubber–styrene butadine rubber (NR–SBR). J Ind Eng Chem 17:264–270. https://doi.org/10.1016/j.jiec.2011.02.019

Rajasekar R, Heinrich G, Das A, Das CK (2009) Development of SBR-nanoclay composites with epoxidized natural rubber as compatibilizer. Res Lett Nanotechnol 2009:1–5. https://doi.org/10.1155/2009/405153

Perera SJ, Egodage SM, Walpalage S (2020) Enhancement of mechanical properties of natural rubber–clay nanocomposites through incorporation of silanated organoclay into natural rubber latex. e-Polym 20(1):144–153. https://doi.org/10.1515/epoly-2020-0017

Wan C, Bao X, Zhao F et al (2008) Morphology and properties of silane-modified montmorillonite clays and clay/PBT composites. J Appl Polym Sci 110:550–557. https://doi.org/10.1002/app.28672

Madhusoodanan KN, Varghese S (2006) Technological and processing properties of natural rubber layered silicate-nanocomposites by melt intercalation process. J Appl Polym Sci 102:2537–2543. https://doi.org/10.1002/app.24680

Khalaf AI, Hegazy MA (2013) Synthesis and characterization of cationic surfactants in the preparation of organobentonite and study their effectiveness on the properties of styrene-butadiene rubber/bentonite composites. High Perform Polym 25:115–125. https://doi.org/10.1177/0954008312456049

Kim M, Kim G, Chowdhury SR (2007) Polybutadiene rubber/organoclay nanocomposites: effect of organoclay with various modifier concentrations on the vulcanization behavior and mechanical properties. Polym Eng Sci 47:308–313. https://doi.org/10.1002/pen.20709

Khalaf AI, Hegazy MA, El-Nashar DE (2017) Synthesis and characterization of cationic gemini surfactant modified Na–bentonite and its applications for rubber nanocomposites. Polym Compos 38:396–403. https://doi.org/10.1002/pc.23598

Gu Z, Gao L, Song G et al (2010) Octadecylammonium montmorillonite/natural rubber/cis-1,4-polybutadiene nanocomposites. Appl Clay Sci 50:143–147. https://doi.org/10.1016/j.clay.2010.07.017

Bao Z, Tao J, Flanigan C (2017) The combination of montmorillonite and silica in styrene–butadiene rubber/polybutadiene rubber tread compounds. Polym Compos 38:918–926. https://doi.org/10.1002/pc.23653

Praveen S, Chattopadhyay PK, Albert P et al (2009) Synergistic effect of carbon black and nanoclay fillers in styrene butadiene rubber matrix: development of dual structure. Compos Part A Appl Sci Manuf 40:309–316. https://doi.org/10.1016/j.compositesa.2008.12.008

Chattopadhyay PK, Das NC, Chattopadhyay S (2011) Influence of interfacial roughness and the hybrid filler microstructures on the properties of ternary elastomeric composites. Compos Part A Appl Sci Manuf 42:1049–1059. https://doi.org/10.1016/j.compositesa.2011.04.011

Jeon GS, Han MH, Seo G (1999) Enhancing adhesion properties between rubber compound and brass-plated steel cord by incorporating silica into rubber. J Adhes Sci Technol 13:153–168. https://doi.org/10.1163/156856199X00361

Tabsan N, Wirasate S, Suchiva K (2010) Abrasion behavior of layered silicate reinforced natural rubber. Wear 269:394–404. https://doi.org/10.1016/j.wear.2010.04.018

Maria HJ, Lyczko N, Nzihou A et al (2014) Stress relaxation behavior of organically modified montmorillonite filled natural rubber/nitrile rubber nanocomposites. Appl Clay Sci 87:120–128. https://doi.org/10.1016/j.clay.2013.10.019

Kim W, Kang B-S, Cho S-G et al (2007) Styrene butadiene rubber-clay nanocomposites using a latex method: morphology and mechanical properties. Compos Interfaces 14:409–425. https://doi.org/10.1163/156855407781291218

Wang M-J (1998) Effect of polymer-filler and filler-filler interactions on dynamic properties of filled vulcanizates. Rubber Chem Technol 71:520–589. https://doi.org/10.5254/1.3538492

Fröhlich J, Niedermeier W, Luginsland H-D (2005) The effect of filler–filler and filler–elastomer interaction on rubber reinforcement. Compos Part A Appl Sci Manuf 36:449–460. https://doi.org/10.1016/j.compositesa.2004.10.004

Acknowledgments

The authors greatly appreciate the support of the Kavir Tire Company to conduct the project.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

A contributed to definition, supervision, and writing the manuscript. B contributed to figure preparation, edition, and characterization. C contributed to experiments. D contributed to rubber experiments.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shiva, M., Ghamari Kargar, P., Seyfollahi, R. et al. Organoclay application in the tire tread base composite. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05326-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05326-6