Abstract

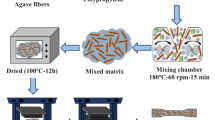

This study is a comparative assessment of polypropylene composites reinforced with two different range size of Agave Americana fibers. The first is from 125 to 630 microns, named as Short Agave Fiber (SHAF), and the second range is beyond 630 microns, named as Long Agave Fiber (LAF). The composites were produced by twin-screw extrusion and injection molding processes. The composite manufacturing by this interior part of plant agave fibers is mentioned in the first time in the literature. The fiber content for the SHAF and LAF composites was chosen as 10 wt. %. It was found that better mechanical properties were achieved with LAF composite which increased by 301.4% compared with the neat PP. This was explained by LAF features compared to SHAF such as the higher cellulose content LAF (73.5%) and SHAF (40.3%), the higher crystallinity index was obtained better thermal stability which led to a composite which is more crystalline, more thermally stable and stiffer. This was explained by the good interfacial adhesion between fibers and the matrix revealed by SEM analysis.

Graphical abstract

Similar content being viewed by others

References

Estaji S, Paydayesh A, Mousavi SR et al (2021) Polycarbonate/poly(methyl methacrylate)/silica aerogel blend composites for advanced transparent thermal insulations: mechanical, thermal, and optical studies. Polym Compos 42:5323–5334. https://doi.org/10.1002/pc.26226

Mousavi SR, Faraj Nejad S, Jafari M, Paydayesh A (2021) Polypropylene/ethylene propylene diene monomer/cellulose nanocrystal ternary blend nanocomposites: effects of different parameters on mechanical, rheological, and thermal properties. Polym Compos 42:4187–4198. https://doi.org/10.1002/pc.26137

Razavi M, Sadeghi N, Jafari SH et al (2022) Thermo-rheological probe of microstructural evolution and degradation pathway in the flame-retarded PP/EVA/NOR/clay nanocomposites. Rheol Acta 61:25–47. https://doi.org/10.1007/s00397-021-01309-w

Mousavi SR, Estaji S, Raouf Javidi M et al (2021) Toughening of epoxy resin systems using core–shell rubber particles: a literature review. J Mater Sci 56:18345–18367. https://doi.org/10.1007/s10853-021-06329-8

Liu T, Huang K, Li L et al (2019) High performance high-density polyethylene/hydroxyapatite nanocomposites for load-bearing bone substitute: fabrication, in vitro and in vivo biocompatibility evaluation. Compos Sci Technol 175:100–110. https://doi.org/10.1016/j.compscitech.2019.03.012

Zhang C, Liu X, Liu H et al (2019) Multi-walled carbon nanotube in a miscible PEO/PMMA blend: thermal and rheological behavior. Polym Test 75:367–372. https://doi.org/10.1016/j.polymertesting.2019.03.003

Jiang L, He C, Fu J, Li X (2018) Wear behavior of alkali-treated sorghum straw fiber reinforced polyvinyl chloride composites in corrosive water conditions. Bio Resources 13(2):3362–3376

Singha AS, Rana RK (2013) Preparation and properties of agave fiber-reinforced polystyrene composites. J Thermoplast Compos Mater 26(4):513–526. https://doi.org/10.1177/0892705711425848

Shi X, Yang P, Peng X et al (2019) Bi-phase fire-resistant polyethylenimine/graphene oxide/melanin coatings using layer by layer assembly technique: smoke suppression and thermal stability of flexible polyurethane foams. Polymer 170:65–75. https://doi.org/10.1016/j.polymer.2019.03.008

Sullins T, Pillay S, Komus A, Ning H (2017) Hemp fi ber reinforced polypropylene composites: the effects of material treatments. Compos B 114:15–22. https://doi.org/10.1016/j.compositesb.2017.02.001

Raza ZA, Riaz S, Banat IM (2018) Polyhydroxyalkanoates: Properties and chemical modification approaches for their functionalization. Biotechnol Prog 34:29–41. https://doi.org/10.1002/btpr.2565

Riaz S, Rhee KY, Park SJ (2021) Polyhydroxyalkanoates (Phas): biopolymers for biofuel and biorefineries. Polymers 13:1–21. https://doi.org/10.3390/polym13020253

Qu M, Nilsson F, Qin Y et al (2017) Electrical conductivity and mechanical properties of melt-spun ternary composites comprising PMMA, carbon fibers and carbon black. Compos Sci Technol 150:24–31. https://doi.org/10.1016/j.compscitech.2017.07.004

Wang X, Pan Y, Qin Y et al (2018) Creep and recovery behavior of injection-molded isotactic polypropylene with controllable skin-core structure. Polym Test 69:478–484. https://doi.org/10.1016/j.polymertesting.2018.05.040

Pan Y, Guo X, Zheng G et al (2018) Shear-induced skin-core structure of molten isotactic polypropylene and the formation of β-crystal. Macromol Mater Eng 303(6):1800083. https://doi.org/10.1002/mame.201800083

Fu S, Yu B, Tang W et al (2018) Mechanical properties of polypropylene composites reinforced by hydrolyzed and microfibrillated Kevlar fibers. Compos Sci Technol 163:141–150. https://doi.org/10.1016/j.compscitech.2018.03.020

Zhang X, Wang X, Liu X et al (2018) Porous polyethylene bundles with enhanced hydrophobicity and pum** oil-recovery ability via skin-peeling. ACS Sustain Chem Eng 6(10):12580–12585. https://doi.org/10.1021/acssuschemeng.8b03305

Zhang F, Liu X, Zheng G et al (2018) Facile route to improve the crystalline memory effect: electrospun composite fiber and annealing. Macromol Chem Phys 219(17):1800236. https://doi.org/10.1002/macp.201800236

Panaitescu DM, Nicolae CA, Vuluga Z et al (2016) Influence of hemp fibers with modified surface on polypropylene composites. J Ind Eng Chem 37:137–146. https://doi.org/10.1016/j.jiec.2016.03.018

Jiang J, Liu X, Lian M et al (2018) Self-reinforcing and toughening isotactic polypropylene via melt sequential injection molding. Polym Test 67:183–189. https://doi.org/10.1016/j.polymertesting.2018.03.005

Liu X, Pan Y, Zheng G et al (2018) Overview of the experimental trends in water-assisted injection molding. Macromol Mater Eng 303(8):1800035. https://doi.org/10.1002/mame.201800035

Taktak I, Mansouri A, Souissi S, Etoh MA, Elloumi A (2023) Biocomposites films based on polylactic acid and olive wood-flour: investigation on physical, thermal and mechanical properties. J Elastom Plast. https://doi.org/10.1177/00952443231165426

Rosli NA, Ahmad I, Abdullah I et al (2015) Hydrophobic modification of cellulose isolated from Agave angustifolia fibre by graft copolymerisation using methyl methacrylate. Carbohyd Polym 125:69–75. https://doi.org/10.1016/j.carbpol.2015.03.002

Hamdi SE, Delisée C, Malvestio J et al (2015) X-ray computed microtomography and 2D image analysis for morphological characterization of short lignocellulosic fibers raw materials: a benchmark survey. Compos A Appl Sci Manuf 76:1–9. https://doi.org/10.1016/j.compositesa.2015.04.019

Taktak I, Mansouri A, Guerfali M et al (2023) Active bio composites films based on PLA/olive wood flour (Olea europaea L.)/cinnamon essential oil. Polym Bull. https://doi.org/10.1007/s00289-023-04737-1

Abraham E, Deepa B, Pothan LA et al (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres: a novel approach. Carbohyd Polym 86:1468–1475. https://doi.org/10.1016/j.carbpol.2011.06.034

Sapuan SM, Pua FL, El-Shekeil YA, Al-Qqla FM (2013) Mechanical properties of soil buried kenaf fibre reinforced thermoplastic polyurethane composites. Mater Des 50:467–470. https://doi.org/10.1016/j.matdes.2013.03.013

Munawar SS, Umemura K, Kawai S (2007) Characterization of the morphological, physical, and mechanical properties of seven nonwood plant fiber bundles. J Wood Sci 53:108–113. https://doi.org/10.1007/s10086-006-0836-x

le Xu Y, Dayo AQ, Wang J et al (2018) Mechanical and thermal properties of a room temperature curing epoxy resin and related hemp fibers reinforced composites using a novel in-situ generated curing agent. Mater Chem Phys 203:293–301. https://doi.org/10.1016/j.matchemphys.2017.10.004

Akin DE, Condon B, Sohn M et al (2007) Optimization for enzyme-retting of flax with pectate lyase. Ind Crops Prod 25:136–146. https://doi.org/10.1016/j.indcrop.2006.08.003

Reddy N, Yang Y (2005) Biofibers from agricultural byproducts for industrial applications. Trends Biotechnol 23:22–27. https://doi.org/10.1016/j.tibtech.2004.11.002

Thamae T, Marien R, Chong L et al (2008) Develo** and characterizing new materials based on waste plastic and agro-fibre. J Mater Sci 43:4057–4068. https://doi.org/10.1007/s10853-008-2495-3

Bilba K, Arsene MA, Ouensanga A (2007) Study of banana and coconut fibers. Botanical composition, thermal degradation and textural observations. Biores Technol 98:58–68. https://doi.org/10.1016/j.biortech.2005.11.030

Hulle A, Kadole P, Katkar P (2015) Agave Americana leaf fibers. Fibers 3(1):64–75

Msahli S, Ydrean J, Sakli F (2005) Evaluating the fineness of Agave Americana L. Fibers Text Res J 75(7):540–543. https://doi.org/10.1177/0040517505053808

Deghboudj S, Boukhedena W, Satha H (2023) Optimization of bending and compressive strength behavior of Agave americana fiber reinforced cementitious composite using response surface methodology. Period Polytech Civ Eng 67:744–756. https://doi.org/10.3311/ppci.21696

Mylsamy K, Rajendran I (2011) The mechanical properties, deformation and thermomechanical properties of alkali treated and untreated Agave continuous fibre reinforced epoxy composites. Mater Des 32:3076–3084. https://doi.org/10.1016/j.matdes.2010.12.051

Mansouri A, Ben Nasr J, Ben Amar M, Elhalouani F (2020) Characterization of fiber extracted from Agave americana after burial in soil. Fibers Polym 21:724–732. https://doi.org/10.1007/s12221-020-8666-9

Jaouadi M, Msahli S, Sakli F (2011) A study of the physical and mechanical properties of paper made from Agave americana L. fibers. Mater Manuf Process 26:567–572. https://doi.org/10.1080/10426910903124878

Bessadok A, Roudesli S, Marais S et al (2009) Etude et caracterisation des fibres d’alfa et d’agave modifiees chimiquement en vue de les incorporer dans un composite amatrice polyester. Compos A Appl Sci Manuf 40:184–195. https://doi.org/10.1016/j.compositesa.2008.10.018

Ortega Z, Castellano J, Suárez L et al (2019) Characterization of Agave americana L. plant as potential source of fibres for composites obtaining. SN Appl Sci 1:1–9. https://doi.org/10.1007/s42452-019-1022-2

Thamarai Selvi S, Sunitha R, Ammayappan L, Prakash C (2023) Impact of chemical treatment on surface modification of Agave Americana fibres for composite application—a futuristic approach. J Nat Fibers. https://doi.org/10.1080/15440478.2022.2142726

Bessghaier A, Oudiani EL (2010) Contribution à l ‘ étude du comportement mécanique des fibres d ‘ Agave Americana L.

Mylsamy K, Rajendran I (2011) Influence of alkali treatment and fibre length on mechanical properties of short Agave fibre reinforced epoxy composites. Mater Des 32:4629–4640. https://doi.org/10.1016/j.matdes.2011.04.029

Henriksson G, Akin DE, Hanlin RT et al (1997) Identification and retting efficiencies of fungi isolated from dew-retted flax in the United States and Europe. Appl Environ Microbiol 63:3950–3956

Akin DE (2013) Linen most useful: perspectives on structure, chemistry, and enzymes for retting flax. ISRN Biotechnol 2013:23. https://doi.org/10.5402/2013/186534

Pickering KL, Efendy MGA, Le TM (2016) A review of recent developments in natural fibre composites and their mechanical performance. Compos Part A 83:98–112. https://doi.org/10.1016/j.compositesa.2015.08.038

Torres-tello EV, Robledo-ortíz JR, González-garcía Y et al (2017) Effect of agave fiber content in the thermal and mechanical properties of green composites based on polyhydroxybutyrate or poly (hydroxybutyrate-co-hydroxyvalerate). Ind Crops Prod 99:117–125. https://doi.org/10.1016/j.indcrop.2017.01.035

Cisneros-l EO (2016) Rotomolded polyethylene-agave fiber composites: effect of fiber surface treatment on the mechanical properties. Polym Eng Sci 56(8):856–865. https://doi.org/10.1002/pen

Edén D, Denis RRG, Omar E et al (2017) Polylactic acid—agave fiber biocomposites produced by rotational molding: a comparative study with compression molding. Adv Polym Technol 37(7):2528–2540. https://doi.org/10.1002/adv.21928

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794. https://doi.org/10.1177/004051755902901003

Moshiul Alam AKM, Beg MDH, Yunus RM et al (2018) Modification of structure and properties of well-dispersed dendrimer coated multi-walled carbon nanotube reinforced polyester nanocomposites. Polym Test 68:116–125. https://doi.org/10.1016/j.polymertesting.2018.04.005

Alam AKMM, Beg MDH, Yunus RM (2017) Microstructure and fractography of multiwalled carbon nanotube reinforced unsaturated polyester nanocomposites. Polym Compos 38:E462–E471. https://doi.org/10.1002/pc.23911

Mustafa WA, Saidi SA, Zainal M, Santiagoo R (2018) Experimental study of composites material based on thermal analysis. J Adv Res Fluid Mech Therm Sci 43:37–44

Morán-Velázquez DC, Monribot-Villanueva JL, Bourdon M et al (2020) Unravelling chemical composition of agave spines: news from Agave fourcroydes Lem. Plants 9:1–15. https://doi.org/10.3390/plants9121642

Madhu P, Sanjay MR, Jawaid M et al (2020) A new study on effect of various chemical treatments on Agave Americana fiber for composite reinforcement: physico-chemical, thermal, mechanical and morphological properties. Polym Testing 85:106437. https://doi.org/10.1016/j.polymertesting.2020.106437

Manimaran P, Senthamaraikannan P, Sanjay MR, Marichelvam MK (2018) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohyd Polym 181:650–658. https://doi.org/10.1016/j.carbpol.2017.11.099

El Oudiani A, Chaabouni Y, Msahli S, Sakli F (2012) Mercerization of Agave americana L. fibers. J Text Inst 103(5):565–574. https://doi.org/10.1080/00405000.2011.590010

Saravanakumar SS, Kumaravel A, Nagarajan T et al (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohyd Polym 92(2):1928–1933. https://doi.org/10.1016/j.carbpol.2012.11.064

Kumar R, Hynes NRJ, Senthamaraikannan P et al (2018) Physicochemical and thermal properties of Ceiba pentandra bark fiber. J Nat Fibers 15:822–829. https://doi.org/10.1080/15440478.2017.1369208

Indran S, Raj RE (2015) Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohyd Polym 117:392–399. https://doi.org/10.1016/j.carbpol.2014.09.072

Yang Q, Pan X (2012) Pretreatment of Agave americana stalk for enzymatic saccharification. Biores Technol 126:336–340. https://doi.org/10.1016/j.biortech.2012.10.018

Sathishkumar TP (2013) Characterization of new cellulose Sansevieria ehrenbergii fibers for polymer composites. Compos Interfaces 20(8):575–593. https://doi.org/10.1080/15685543.2013.816652

Indran S, Raj RE, Sreenivasan VS (2014) Characterization of new natural cellulosic fiber from Cissus quadrangularis root. Carbohyd Polym 110:423–429. https://doi.org/10.1016/j.carbpol.2014.04.051

De Rosa IM, Kenny JM, Puglia D et al (2010) Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos Sci Technol 70(1):116–122. https://doi.org/10.1016/j.compscitech.2009.09.013

Ganeshan P, NagarajaGanesh B, Ramshankar P, Raja K (2018) Calotropis gigantea fibers: a potential reinforcement for polymer matrices. Int J Polym Anal Charact 23(3):271–277. https://doi.org/10.1080/1023666X.2018.1439560

Porras A, Maranon A, Ashcroft IA (2015) Characterization of a novel natural cellulose fabric from Manicaria saccifera palm as possible reinforcement of composite materials. Compos B Eng 74:66–73. https://doi.org/10.1016/j.compositesb.2014.12.033

Reddy KO, Zhang J, Zhang J, Rajulu AV (2014) Preparation and properties of self-reinforced cellulose composite films from Agave microfibrils using an ionic liquid. Carbohyd Polym 114:537–545. https://doi.org/10.1016/j.carbpol.2014.08.054

De Rosa IM, Kenny JM, Maniruzzaman M et al (2011) Effect of chemical treatments on the mechanical and thermal behaviour of okra (Abelmoschus esculentus) fibres. Compos Sci Technol 71(2):246–254. https://doi.org/10.1016/j.compscitech.2010.11.023

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Yanuhar U, Permanasari AA, Fikri AA et al (2017) Pulsed electric field assisted extraction of cellulose from mendong fiber (Fimbristylis globulosa) and its characterization. J Nat Fibers 15(3):406–415. https://doi.org/10.1080/15440478.2017.1330722

Subramanian K, Senthil Kumar P, Jeyapal P, Venkatesh N (2005) Characterization of ligno-cellulosic seed fibre from Wrightia Tinctoria plant for textile applications-an exploratory investigation. Eur Polym J 41:853–861. https://doi.org/10.1016/j.eurpolymj.2004.10.037

Pereira SC, Maehara L, Machado CMM, Farinas CS (2016) Physical-chemical-morphological characterization of the whole sugarcane lignocellulosic biomass used for 2G ethanol production by spectroscopy and microscopy techniques. Renew Energy 87:607–617. https://doi.org/10.1016/j.renene.2015.10.054

Jcc S, George N, Narayanankutty SK (2016) Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohyd Polym 142:158–166. https://doi.org/10.1016/j.carbpol.2016.01.015

Raja K, Prabu B, Ganeshan P et al (2021) Characterization studies of natural cellulosic fibers extracted from shwetark stem. J Nat Fibers 18:1934–1945. https://doi.org/10.1080/15440478.2019.1710650

Manivel S, Pannirselvam N, Gopinath R, Sathishkumar TP (2022) Physico-mechanical, chemical composition and thermal properties of cellulose fiber from hibiscus vitifolius plant stalk for polymer composites. J Nat Fibers 19:6961–6976. https://doi.org/10.1080/15440478.2021.1941484

Gopinath R, Billigraham P, Sathishkumar TP (2023) Characterization studies on new cellulosic fiber extracted from Leucaena Leucocephala tree. J Nat Fibers. https://doi.org/10.1080/15440478.2022.2157922

Siva R, Valarmathi TN, Palanikumar K, Samrot AV (2020) Study on a novel natural cellulosic fiber from Kigelia africana fruit: characterization and analysis. Carbohyd Polym. https://doi.org/10.1016/j.carbpol.2020.116494

Yan Z, Chen S, Wang H et al (2008) Cellulose synthesized by Acetobacter xylinum in the presence of multi-walled carbon nanotubes. Carbohyd Res 343:73–80. https://doi.org/10.1016/j.carres.2007.10.024

El OA, Chaabouni Y, Msahli S, Sakli F (2011) Crystal transition from cellulose i to cellulose II in NaOH treated Agave americana L. fibre. Carbohyd Polym 86:1221–1229. https://doi.org/10.1016/j.carbpol.2011.06.037

Moshiul Alam AKM, Beg MDH, Reddy Prasad DM et al (2012) Structures and performances of simultaneous ultrasound and alkali treated oil palm empty fruit bunch fiber reinforced poly(lactic acid) composites. Compos A Appl Sci Manuf 43:1921–1929. https://doi.org/10.1016/j.compositesa.2012.06.012

Fiore V, Scalici T, Valenza A (2014) Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohyd Polym 106:77–83. https://doi.org/10.1016/j.carbpol.2014.02.016

Belouadah Z, Ati A, Rokbi M (2015) Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohyd Polym 134:429–437. https://doi.org/10.1016/j.carbpol.2015.08.024

Nagarajaganesh B, Rengarajan M (2016) Physico-chemical, thermal, and flexural characterization of Cocos nucifera fibers. Int J Polym Anal Charact 21(3):244–250. https://doi.org/10.1080/1023666X.2016.1139359

Siakeng R, Jawaid M, Ariffin H, Sapuan SM (2018) Thermal properties of coir and pineapple leaf fibre reinforced polylactic acid hybrid composites. IOP Conf Ser Mater Sci Eng 368(1):012019. https://doi.org/10.1088/1757-899X/368/1/012019

Haddar M, Elloumi A, Koubaa A et al (2018) Synergetic effect of Posidonia oceanica fibres and deinking paper sludge on the thermo-mechanical properties of high density polyethylene composites industrial crops & products synergetic effect of Posidonia oceanica fibres and deinking paper sludge on. Ind Crops Prod 121:26–35. https://doi.org/10.1016/j.indcrop.2018.04.075

Boussetta A, Charii H, Ait Benhamou A et al (2023) Bio-composites based on cellulosic fibers from agro-industrial waste filled PP matrix: production and properties. Polym Bull. https://doi.org/10.1007/s00289-023-04698-5

Rahman WA, Nur S, Sudin A, Din SN (2012) Physical and mechanical properties of Pandanus amaryllifolius fiber reinforced low density polyethylene composite for packaging application. In: 2012 IEEE symposium on humanities, science and engineering research 345–349

Maheshwaran MV, Hyness NRJ, Senthamaraikannan P et al (2018) Characterization of natural cellulosic fiber from Epipremnum aureum stem. J Nat Fibers 15:789–798. https://doi.org/10.1080/15440478.2017.1364205

Sari NH, Wardana ING, Irawan YS et al (2017) Characterization of the chemical, physical, and mechanical properties of NaOH-treated natural cellulosic fibers from corn husks. J Nat Fibers 15(4):545–558. https://doi.org/10.1080/15440478.2017.1349707

Cisneros-López O, Anzaldo J, Fuentes-Talavera FJ et al (2015) Effect of agave fiber surface treatment on the properties of polyethylene composites produced by dry-blending and compression molding. Polym Compos 38(1):96–104

Perić M, Putz R, Paulik C (2019) Influence of nano fibrillated cellulose on the mechanical and thermal properties of poly (lactic acid ). Eur Polym J 114:426–433. https://doi.org/10.1016/j.eurpolymj.2019.03.014

El Oudiani A, Chaabouni Y, Msahli S, Sakli F (2009) Physico-chemical characterisation and tensile mechanical properties of Agave americana L. fibres. J Text Inst 100(5):430–439. https://doi.org/10.1080/00405000701863350

Shanmugasundaram N, Rajendran I, Ramkumar T (2018) Characterization of untreated and alkali treated new cellulosic fiber from an Areca palm leaf stalk as potential reinforcement in polymer composites. Carbohyd Polym 195:566–575. https://doi.org/10.1016/j.carbpol.2018.04.127

Riaz S, Park SJ (2021) A comparative study on nanoinclusion effect of MoS2 nanosheets and MoS2 quantum dots on fracture toughness and interfacial properties of epoxy composites. Compos A Appl Sci Manuf 146:106419. https://doi.org/10.1016/j.compositesa.2021.106419

Riaz S, Park SJ (2020) Effective reinforcement of melamine-functionalized WS2 nanosheets in epoxy nanocomposites at low loading via enhanced interfacial interaction. Macromol Res 28:1116–1126. https://doi.org/10.1007/s13233-020-8151-8

Benhamou A, Boussetta A, Grimi N, El IM (2021) Characteristics of cellulose fibers from opuntia ficus indica cladodes and its use as reinforcement for PET-based composites characteristics of cellulose fibers from opuntia ficus indica cladodes and its use as reinforcement for PET based composites. J Nat Fibers 00:1–17. https://doi.org/10.1080/15440478.2021.1904484

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mansouri, A., Ben Nasr, J. & Ben Amar, M. Biocomposites based on polypropylene and Agave fibers (Agave Americana L): investigation on physical, thermal and mechanical properties. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05317-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05317-7