Abstract

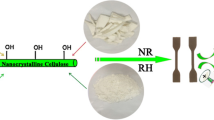

In this work, the green material based on epoxidized natural rubber (ENR) and modified cellulose were prepared through a completely eco-friendly procedure. Cellulose was extracted from sugarcane bagasse through removal of hemicellulose and lignin by a simple method. Thereafter, purified cellulose was modified by graft-copolymerization of acrylonitrile in the presence of ammonium persulfate initiator in emulsion state. The obtained cellulose was blended with ENR in molten state. The structural characterization through FT-IR spectroscopy confirmed that polyacrylonitrile was successfully grafted on cellulose. The optimal condition for graft-copolymerization was found at 5 °C and ammonium persulfate concentration of 0.022 mol/kg cellulose, at which the highest nitrogen content of the resulting material was 2.82 wt%. The blend of ENR cellulose-graft-polyacrylonitrile of which the nitrogen content is 2.82 wt% (Cel-Pan-2.82) expressed the outstanding properties in term of tensile strength, hardness, thermal resistance, and self-cleaning. The tensile strength and hardness of the blend containing 10 wt% of Cel-Pan-2.82 was 6.5 MPa and 49.0, respectively; those of the blend containing 20 wt% of Cel-Pan-2.82 was 5.5 MPa and 59.5, respectively. The mechanical properties of the blends were better than those of ENR. The initial decomposition temperature of the blends was 150 °C higher than that of ENR. The contact angle of the blends containing Cel-Pan-2.82 was about 12–25° higher than that of ENR, which confirmed the waterproof of the blends. SEM observation confirmed the fine dispersion of Cel-Pan-2.82 in ENR. The improvement in the properties of the blends was attributed to the effect of polyacrylonitrile which enhanced the compatibility of ENR phase and cellulose phase.

Similar content being viewed by others

References

Yua L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602. https://doi.org/10.1016/j.progpolymsci.2006.03.002

Hon DNS (1994) Cellulose: a random walk along its historical path. Cellulose 1:1–25. https://doi.org/10.1007/BF00818796

Bokobza L (2019) Natural rubber nanocomposites: a review. Nanomaterials 9:1–21. https://doi.org/10.3390/nano9010012

Amram B, Bokobza L, Queslel JP, Monnerie L (1986) Fourier-transform infrared dichroism study of molecular orientation in synthetic high cis-1,4-polyisoprene and in natural rubber. Polymer 27:877–882. https://doi.org/10.1016/0032-3861(86)90298-3

Hamad W (2006) On the development and applications of cellulosic nanofibrillar and nanocrystalline materials. Can J Chem Eng 84:513–519. https://doi.org/10.1002/cjce.5450840501

Bendahou A, Kaddami H, Dufresne A (2010) Investigation on the effect of cellulosic nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur Polym J 46:609–620. https://doi.org/10.1016/j.eurpolymj.2009.12.025

Eichhorn SJ (2011) Cellulose nanowhiskers: promising materials for advanced applications. Soft Matter 7:303–315

Khattab TA, Abdelrahman MS, Ahmed HB, Emam HE (2020) Molecularly imprinted cellulose sensor strips for selective determination of phenols in aqueous environment. Fibers Polym 21:2195–2203. https://doi.org/10.1007/s12221-020-1325-3

Hashem AH, Hasanin M, Kamel S, Dacrory S (2022) A new approach for antimicrobial and antiviral activities of biocompatible nanocomposite based on cellulose, amino acid and graphene oxide. Colloids Surf, B 209:112172. https://doi.org/10.1016/j.colsurfb.2021.112172

Asagekar SD, Joshi VK (2014) Characteristics of sugarcane fibers. Indian J Fibre Text Res 39:80–184

Dannenberg EM (1975) The effects of surface chemical interactions on the properties of filler-reinforced rubbers. Rubb Chem Technol 48:410–444

Huneau B (2011) Strain-induced crystallization of natural rubber: A review of X-ray diffraction investigations. Rubb Chem Technol 84:425–452

Bradbury JH, Perera MCS (1988) Advances in the epoxidation of unsaturated polymers. Ind Eng Chem Res 27:2196–2203

Halasa AF, Massie JM, Ceresa RJ (2013) The chemical modification of polymers. In: Mark JE, Roland CM (eds) Erman B. The Science and Technology of Rubber Academic Press, Oxford, pp 517–546. https://doi.org/10.1016/B978-0-12-394584-6.00011-X

Bokobza L (2004) The reinforcement of elastomeric networks by fillers. Macromol Mater Eng 289:607–621

Ashori A, Tabarsa T, Valizadeh I (2011) Fiber reinforced cement boards made from recycled newsprint paper. Mater Sci Eng A 528:7801–7804

Mohan TP, Kanny K (2012) Chemical treatment of sisal fiber using alkali and clay method. Compos A: Appl Sci Manuf 43:1989–1998

Gürdag G, Güclü G, Ozgümüs S (2001) Graft copolymerization of acrylic acid onto cellulose: effects of pre-treatments and crosslinking agent. J Appl Polym Sci 80:2267–2272

Sreekumar PA, Saiah R, Saiter JM, Leblanc N, Joseph K, Unnikrishnan G, Thomas S (2008) Effect of chemical treatment on dynamic mechanical properties of sisal fiber-reinforced polyester composites fabricated by resin transfer molding. Compos Interf 15:263–279. https://doi.org/10.1163/156855408783810858

Abdel-Hakim A, Mourad RM (2019) Mechanical, water uptake properties, and biodegradability of polystyrene-coated sisal fiber-reinforced high-density polyethylene. Polym Compos 41:1435–1446

Rosa MF, Medeiros ES, Malmonge JA, Gregorski KS, Wood DF, Mattoso LHC, Imam SH (2010) Cellulose nanowhiskers from coconut husk fibers: effect of preparation conditions on their thermal and morphological behavior. Carbohyd Polym 81:83–92

Yan H, Hua Z, Qian G, Wang M, Du G, Chen J (2009) Analysis of the chemical composition of cotton seed coat by fourier-transform infrared (FT-IR) microspectroscopy. Cellulose 16:1099–1107

Xu F, Yu J, Tesso T, Dowell F, Wang D (2013) Qualitative and quantitative analysis of lignocellulosic biomass using infrared techniques: a mini-review. Appl Energy 104:801–809

Kim HJ, Liu Y, French AD, Lee CM, Kim SH (2018) Comparison and validation of fourier transform infrared spectroscopic methods for monitoring secondary cell wall cellulose from cotton fibers. Cellulose 25:49–64

Kakida H, Tashiro K (1997) Mechanism and kinetics of stabilization reactions of polyacrylonitrile and related copolymers III Comparison among the various types of copolymers as viewed from isothermal DSC thermograms and FT-IR spectral changes. Polym J 29:557–562

Lignier P, Estager J, Kardos N, Gravouil L, Gazza J, Naffrechoux E, Draye M (2011) Swift and efficient sono-hydrolysis of nitriles to carboxylic acids under basic condition: Role of the oxide anion radical in the hydrolysis mechanism. Ultrason Sonochem 18:28–31

Enomoto-Rogers Y, Kamitakahara H, Nakayama K, Takano T, Nakatsubo F (2009) Synthesis and thermal properties of poly(methyl methacrylate)-graft-(cellobiosylamine-C15). Cellulose 16:519–530. https://doi.org/10.1007/s10570-008-9272-y

Pukkate N, Yamamoto Y, Kawahara S (2008) Mechanism of graft copolymerization of styrene onto deproteinized natural rubber. Colloid Polym Sci 286:411–416

Gromadzki D, Lokaj J, Cernoch P, Diat O, Nallet F, Stepanek P (2008) Morphology of polystyrene-block-poly(styrene-co-acrylonitrile) and polystyrene-block-poly(styrene-co-acrylonitrile-co-5-vinyltetrazole) diblock copolymers prepared by nitroxide-mediated radical polymerization and ‘‘click” chemistry. Eur Polym J 44:189–199

Duh YS, Ho TC, Chen JR, Kao CS (2010) Study on exothermic oxidation of acrylonitrile-butadiene-styrene (ABS) resin powder with application to ABS processing safety. Polymers 2:174–187

Thongnuanchan B, Nokkaew K, Kaesaman A, Nakason C (2007) Epoxidized natural rubber-boned para rubber wood particleboard. Polym Eng Sci 47:421–428

Acknowledgements

This research is funded by Hanoi University of Science and Technology (HUST) under project number T2021-TĐ-003.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, T.H., Tran, V.C., Nguyen, M.T. et al. Preparation of green material based on sugarcane bagasse and epoxidized natural rubber. Polym. Bull. 80, 3359–3375 (2023). https://doi.org/10.1007/s00289-022-04219-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04219-w