Abstract

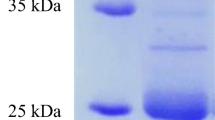

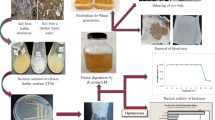

Enormous aggregates of keratinous wastes are produced annually by the poultry and leather industries which cause environmental degradation globally. To combat this issue, microbially synthesized extracellular proteases known as keratinase are used widely which is effective in degrading keratin found in hair and feathers. In the present work, keratinolytic bacteria were isolated from poultry farm soil and feather waste, and various cultural conditions were optimized to provide the highest enzyme production for efficient keratin waste degradation. Based on the primary and secondary screening methods, the potent keratinolytic strain (HFS_F2T) with the highest enzyme activity 32.65 ± 0.16 U/mL was genotypically characterized by 16S rRNA sequencing and was confirmed as Bacillus velezensis HFS_F2T ON556508. Through one-variable-at-a-time approach (OVAT), the keratinase production medium was optimized with sucrose (carbon source), beef extract (nitrogen source) pH-7, inoculum size (5%), and incubation at 37 °C). The degree of degradation (%DD) of keratin wastes was evaluated after 35 days of degradation in the optimized keratinase production medium devoid of feather meal under submerged fermentation conditions. Further, the deteriorated keratin wastes were visually examined and the hydrolysed bovine hair with 77.32 ± 0.32% degradation was morphologically analysed through Field Emission Scanning Electron Microscopy (FESEM) to confirm the structural disintegration of the cuticle. Therefore, the current study would be a convincing strategy for reducing the detrimental impact of pollutants from the poultry and leather industries by efficient keratin waste degradation through the production of microbial keratinase.

Graphical Abstract

Similar content being viewed by others

Availability of Data and Materials

Not applicable.

References

Anbesaw MS (2022) Bioconversion of keratin wastes using keratinolytic microorganisms to generate value-added products. Int J Biomater. https://doi.org/10.1155/2022/2048031

Sharma S, Gupta A (2016) Sustainable management of keratin waste biomass: applications and future perspectives. Braz Arch Biol Technol 59:1–14. https://doi.org/10.1590/1678-4324-2016150684

Akhter M, Wal Marzan L, Akter Y, Shimizu K (2020) Microbial bioremediation of feather waste for keratinase production: an outstanding solution for leather detailing in tanneries. Microbiol Insights 13:1178636120913280. https://doi.org/10.1177/1178636120913280

Onifade A, Al-Sane N, Al-Musallam A, Al-Zarban S (1998) A review: potentials for biotechnological applications of keratin-degrading microorganisms and their enzymes for nutritional improvement of feathers and other keratins as livestock feed resources. Bioresour Technol 66:1–11. https://doi.org/10.1016/S0960-8524(98)00033-9

Kokilan R, Priya BD (2022) A sustainable approach for processing organic waste in India. Mater Today 64:1069–1074. https://doi.org/10.1016/j.matpr.2022.05.291

Williams CM, Lee CG, Garlich JD, Shih JC (1991) Evaluation of a bacterial feather fermentation product, feather-lysate, as a feed protein. Poult Sci 70(1):85–94. https://doi.org/10.3382/ps.0700085

Saber WIA, El-Metwally MM, El-Hersh MS (2010) Keratinase production and biodegradation of some keratinous wastes by Alternaria tenuissima and Aspergillus nidulans. Res J Microbiol 5(1):21–35

Kumawat TK, Sharma A, Sharma V, Chandra S (2018) Keratin waste: the biodegradable polymers. In Keratin. IntechOpen

Da Silva, R. R. (2018). Keratinases as an alternative method designed to solve keratin disposal on the environment: its relevance on agricultural and environmental chemistry, 7219–7221. https://doi.org/10.1021/acs.jafc.8b03152

Sharma I, Pranaw K, Soni H et al (2022) Parametrically optimized feather degradation by Bacillus velezensis NCIM 5802 and delineation of keratin hydrolysis by multi-scale analysis for poultry waste management. Sci Rep 12:17118. https://doi.org/10.1038/s41598-022-21351-9

Sharma R, Devi S (2018) Versatility and commercial status of microbial keratinases: a review. Rev Environ Sci Bio/Technol 17(1):19–45. https://doi.org/10.1007/s11157-017-9454-x

Li Q (2019) Progress in microbial degradation of feather waste. Front Microbiol 10:2717. https://doi.org/10.3389/fmicb.2019.02717

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70:21–33. https://doi.org/10.1007/s00253-005-0239-8

Yamamura S, Morita Y, Hasan Q, Yokoyama K, Tamiya E (2002) Keratin degradation: a cooperative action of two enzymes from Stenotrophomonas sp. Biochem Biophys Res Commun 294(5):1138–1143. https://doi.org/10.1016/s0006-291x(02)00580-6

Vidmar B, Vodovnik M (2018) Microbial keratinases: enzymes with promising biotechnological applications. Food Technol Biotechnol 56(3):312–328. https://doi.org/10.17113/ftb.56.03.18.5658

Tamreihao K, Mukherjee S, Khunjamayum R, Devi LJ, Asem RS, Ningthoujam DS (2019) Feather degradation by keratinolytic bacteria and biofertilizing potential for sustainable agricultural production. J Basic Microbiol 59(1):4–13. https://doi.org/10.1002/jobm.201800434

Williams CM, Shih JCH (1989) Enumeration of some microbial groups in thermophilic poultry waste digesters and enrichment of a feather-degrading culture. J Appl Bacteriol 67(1):25–35. https://doi.org/10.1111/j.1365-2672.1989.tb04951.x

Chaturvedi V, Bhange K, Bhatt R, Verma P (2014) Production of kertinases using chicken feathers as substrate by a novel multifunctional strain of Pseudomonas stutzeri and its dehairing application. Biocatal Agric Biotechnol 3(2):167–174. https://doi.org/10.1016/j.bcab.2013.08.005

Bohacz J, Korniłłowicz-Kowalska T (2019) Fungal diversity and keratinolytic activity of fungi from lignocellulosic composts with chicken feathers. Process Biochem 80:119–128. https://doi.org/10.1016/j.procbio.2019.02.012

Manczinger L, Rozs M, Vágvölgyi C, Kevei F (2003) Isolation and characterization of a new keratinolytic Bacillus licheniformis strain. World J Microbiol Biotechnol 19(1):35–39. https://doi.org/10.1023/A:1022576826372

Gupta S, Singh R (2014) Hydrolyzing proficiency of keratinases in feather degradation. Indian J Microbiol 54(4):466–470. https://doi.org/10.1007/s12088-014-0477-5

Brandelli A, Sala L, Kalil SJ (2015) Microbial enzymes for bioconversion of poultry waste into added-value products. Food Res Int 73:3–12. https://doi.org/10.1016/j.foodres.2015.01.015

Kang D, Herschend J, Al-Soud WA, Mortensen MS, Gonzalo M, Jacquiod S, Sørensen SJ (2018) Enrichment and characterization of an environmental microbial consortium displaying efficient keratinolytic activity. Biores Technol 270:303–310. https://doi.org/10.1016/j.biortech.2018.09.006

Barman NC, Zohora FT, Das KC, Mowla M, Banu NA, Salimullah M, Hashem A (2017) Production, partial optimization and characterization of keratinase enzyme by Arthrobacter sp. NFH5 isolated from soil samples. AMB Express 7(1):1–8. https://doi.org/10.1186/s13568-017-0462-6

Sekar V, Kannan M, Ganesan R, Dheeba B, Sivakumar N, Kannan K (2016) Isolation and screening of keratinolytic bacteria from feather dum** soil in and around Cuddalore and Villupuram, Tamil Nadu. Proc Natl Acad Sci India Sect B 86:567–575. https://doi.org/10.1007/s40011-014-0483-8

Tork S, Aly M, Nawar L (2010) Biochemical and molecular characterization of a new local keratinase producing Pseudomomanas sp., MS21. Asian J Biotechnol 2:1–13

Rajesh TP, Rajasekar S, Mathan RKH, Anandaraj B (2016) Isolation and identification of feather degrading bacteria from feather-dumped soil. Int J Environ Sustain Dev 15:293–299. https://doi.org/10.1504/IJESD.2016.077393

MacDonald CE, Chen LL (1965) Lowry modification of the Folin reagent for determination of proteinase activity. Anal Biochem 10:175. https://doi.org/10.1016/0003-2697(65)90255-1

Gowdhaman D, Ponnusami V (2014) Production of keratinase from a new strain of Pseudomonas aeruginosa gmp and its application for the removal of dyed keratin waste. Bioresour Technol 9(5):210–217

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin’s phenol reagent. J Biol Chem 193:265–275

Vos P, Garrity G, Jones D, Krieg NR, Ludwig W, Rainey FA, Schleifer K-H, Whitman WB (2011) Bergey’s manual of systematic bacteriology: Volume 3: The Firmicutes. Springer, New York

Butler JM (2011) Advanced topics in forensic DNA ty**: methodology. Academic Press, Washington

Abid S, Farid A, Abid R, Rehman MU, Alsanie WF, Alhomrani M, Ghazanfar S (2022) Identification, biochemical characterization, and safety attributes of locally isolated Lactobacillus fermentum from Bubalus bubalis (buffalo) milk as a probiotic. Microorganisms 10(5):954. https://doi.org/10.3390/microorganisms10050954

Sadiqi S, Hamza M, Ali F, Alam S, Shakeela Q, Ahmed S, Zaman W (2022) Molecular characterization of bacterial isolates from soil samples and evaluation of their antibacterial potential against MDRS. Molecules 27(19):6281

Zhou L, Liu Y, Sun H, Li H, Zhang Z, Hao P (2022) Usefulness of enzyme-free and enzyme-resistant detection of complement component 5 to evaluate acute myocardial infarction. Sens Actuators B 369:132315. https://doi.org/10.1016/j.snb.2022.132315

Masih H, Singh S (2014) Degradation of keratinous waste products by keratinolytic bacteria isolated from soil. Int J Eng Comp Sci 3:7588–7595

Ahmad S, Ahmad M, Fawzy Ramadan M, Sultana S, Papini A, Ullah F, Zafar M (2023) Palynological study of fossil plants from miocene murree formation of Pakistan: clues to investigate palaeoclimate and palaeoenvironment. Agronomy 13(1):269. https://doi.org/10.3390/agronomy13010269

Bahadur S, Long W, Ahmad M, Yaseen M, Ullah F, Saqib S (2023) Exploration of pollen traits and their taxonomic relevance in selected taxa of the subfamily Papilionoideae from Hainan Island, China. Palynology 47(2):2144521. https://doi.org/10.1080/01916122.2022.2144521

Madkour FA, Abdelsabour-Khalaf M (2022) Performance scanning electron microscopic investigations and elemental analysis of hair of the different animal species for forensic identification. Microsc Res Tech 85(6):2152–2161. https://doi.org/10.1002/jemt.24073

Akram F, Aqeel A, Shoaib M, Haq IU, Shah FI (2022) Multifarious revolutionary aspects of microbial keratinases: an efficient green technology for future generation with prospective applications. Environ Sci Pollut Res 29(58):86913–86932. https://doi.org/10.1007/s11356-022-23638-w

Pei, X. D., Li, F., Zhang, Y. M., Huang, X. N., Yu, F. T., Su, L. Y., ... & Wang, C. H. (2023). Preparation, Purification, and Identification of Novel Feather Keratin-Derived Peptides with Antioxidative and Xanthine Oxidase Inhibitory Activities. Journal of Agricultural and Food Chemistry. https://doi.org/10.1021/acs.jafc.3c01131

Yadav S, Bumbra P, Laura JS, Khosla B (2022) Optimization of nutritional and physical parameters for enhancing the keratinase activity of Bacillus cereus isolated from soil of poultry dump site in Gurugram, Haryana. Bioresource Technol Rep 18:101108. https://doi.org/10.1016/j.biteb.2022.101108

Jagadeesan Y, Meenakshisundaram S, Saravanan V, Balaiah A (2020) Sustainable production, biochemical and molecular characterization of thermo-and-solvent stable alkaline serine keratinase from novel Bacillus pumilus AR57 for promising poultry solid waste management. Int J Biol Macromol 163:135–146. https://doi.org/10.1016/j.ijbiomac.2020.06.219

Revankar AG, Bagewadi ZK, Bochageri NP, Khan TY, Shamsudeen SM (2023) Response surface methodology based optimization of keratinase from Bacillus velezensis strain ZBE1 and nanoparticle synthesis, biological and molecular characterization. Saudi J Biol Sci 30(10):103787. https://doi.org/10.1016/j.sjbs.2023.103787

Sutoyo S, Subandi S, Ardyati T, Suharjono S (2019) Isolation and identification of keratinolytic bacteria from Jember, Indonesia as a biodegradation agent of chicken feather wastes. Asian J Agric Biol 7(4):491–500

Zambare VP, Nilegaonkar SS, Kanekar PP (2007) Production of an alkaline protease by Bacillus cereus MCM B-326 and its application as a dehairing agent. World J Microbiol Biotechnol 23:1569–1574. https://doi.org/10.1007/s11274-007-9402-y

Qadar SA, Shireen E, Iqbal S, Anwar A (2009) Optimization of protease production from newly isolated strain of Bacillus sp. PCSIR EA-3

Abdelmoteleb A, Gonzalez-Mendoza D, Tzintzun-Camacho O, Grimaldo-Juárez O, Mendez-Trujillo V, Moreno-Cruz C, Roumia AF (2023) Keratinases from Streptomyces netropsis and Bacillus subtilis and their potential use in the chicken feather degrading. Fermentation 9(2):96. https://doi.org/10.3390/fermentation9020096

Deba F, Nelofer R, Irfan M (2023) Isolation, identification, and screening of keratinase producing bacteria from soil and production optimization using feather waste as substrate. Punjab Univ J Zool 38(1):109–118. https://doi.org/10.17582/journal.pujz/2023.38.1.109.118

Subugade S, Gupta SG, Mokashe S (2017) Isolation and screening of keratinase producing bacteria from chicken feather dum** site. Int J ChemTech Res 10:900–905

Kainoor PS, Naik GR (2010) Production and characterization of feather degrading keratinase from Bacillus sp. JB 99

Lateef A, Oloke JK, Kana EG, Sobowale BO, Ajao SO, Bello BY (2010) Keratinolytic activities of a new feather-degrading isolate of Bacillus cereus LAU 08 isolated from Nigerian soil. Int Biodeterior Biodegrad 64(2):162–165. https://doi.org/10.1016/j.ibiod.2009.12.007

Suntornsuk W, Suntornsuk L (2003) Feather degradation by Bacillus sp. FK 46 in submerged cultivation. Bioresource Technol 86(3):239–243. https://doi.org/10.1016/S0960-8524(02)00177-3

Cai C, Zheng X (2009) Medium optimization for keratinase production in hair substrate by a new Bacillus subtilis KD-N2 using response surface methodology. J Ind Microbiol Biotechnol 36(7):875–883. https://doi.org/10.1007/s10295-009-0565-4

Singh S, Masih H, Jeyakumar GE, Lawrence R, Ramteke PW (2017) Optimization of fermentative production of keratinase by Bacillus subtilis strain S1 in submerged state fermentation using feather waste. Int J Curr Microbiol App Sci 6(12):1499–1510. https://doi.org/10.20546/ijcmas.2017.612.167

Lal S, Rajak RC, Hasija SK (1999) In vitro degradation of keratin by two species of Bacillus. J Gen Appl Microbiol 45(6):283–287. https://doi.org/10.2323/jgam.45.283

Beryl GP, Thazeem B, Umesh M (2021) Bioconversion of feather composts using proteolytic Bacillus mycoides for their possible application as biofertilizer in agriculture. Waste Biomass Valor 12:6795–6809. https://doi.org/10.1007/s12649-021-01472-4

Desai SS, Hegde S, Inamdar P, Sake N, Aravind MS (2010) Isolation of keratinase from bacterial isolates of poultry soil for waste degradation. Eng Life Sci 10(4):361–367. https://doi.org/10.1002/elsc.200900009

Hassan MA, Haroun BM, Amara AA, Serour EA (2013) Production and characterization of keratinolytic protease from new wool-degrading Bacillus species isolated from Egyptian ecosystem. BioMed Res Intl 2013:1–14. https://doi.org/10.1155/2013/175012

Thankaswamy SR, Sundaramoorthy S, Palanivel S, Ramudu KN (2018) Improved microbial degradation of animal hair waste from leather industry using Brevibacterium luteolum (MTCC 5982). J Clean Prod 189:701–708. https://doi.org/10.1016/j.jclepro.2018.04.095

Bressollier P, Letourneau F, Urdaci M, Verneuil B (1999) Purification and characterization of a keratinolytic serine proteinase from Streptomyces albidoflavus. Appl Environ Microbiol 65(6):2570–2576

Atalo K, Gashe BA (1993) Protease production by a thermophilic Bacillus species (P-001A) which degrades various kinds of fibrous proteins. Biotech Lett 15:1151–1156. https://doi.org/10.1007/BF00131207

Acknowledgements

The authors thank the Department of Science and Technology (DST) for supporting the Department of Microbial Biotechnology, Bharathiar University, Tamil Nadu under the DST-FIST scheme to have the necessary facilities for the successful execution of this research work.

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All the authors contributed to the fulfilment of the manuscript. Concept, experiment, material preparation, data collection, and analysis were performed by KS and AV. The first draft of the manuscript was written by KS. The corresponding author, Dr. PK commented on previous versions of the manuscript and proofread and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

Not applicable.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Saravanan, K., Vijayaveeran, A. & Kathirvel, P. Biodegradation of Keratin Waste by Bacillus velezensis HFS_F2 through Optimized Keratinase Production Medium. Curr Microbiol 81, 179 (2024). https://doi.org/10.1007/s00284-024-03699-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00284-024-03699-5