Abstract

Crushed and ground printed circuit board (PCB) samples were characterized to evaluate copper, lead, and aluminum using X-ray fluorescence spectroscopy (XRF) and the morphology was done by scanning electron microscopy (SEM). The XRF characterizations showed 0.12% lead, 3.72% copper, and 12.73% aluminum in the PCBs. The metal solubilization experiments using Acidithiobacillus ferrooxidans indicated higher values of total metal solubilization when the initial pH of the inoculum was adjusted. However, these experiments did not show higher metal solubilization by bioleaching. The sequential bioremoval experiments using mixed culture after bioleaching assays with A. ferrooxidans with initial adjustment of inoculum pH and without applying a magnetic field removed 100% of Al, 27.34% of Cu, and 96.43% of Pb from the lixiviate medium; with magnetic field application, 100% of Al, 83.82% of Cu, and 98.27% of Pb were removed. A similar bioleaching experiment without inoculum pH adjustment and without field application achieved 99.74% removal for Cu and 91.92% for Pb. When the magnetic field was applied, 100% of Cu and 95.76% of Pb were removed. Bioreactors with a magnetic field do not show significantly better removal of any of the metals analyzed.

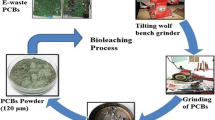

Graphical Abstract

Similar content being viewed by others

References

Forti V, Baldé CP, Kuehr R, Bel G, The Global E-waste Monitor (2020) Quantities, Flows and the Circular Economy Potential. United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—co-hosted SCYCLE Programme, International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Rotterdam

Demajorovic J, Augusto EGF, de Souza MTS (2016) Reverse logistics of e-waste in develo** countries. Ambiente Sociedade São Paulo 5(2):117–136

Awasthi AK, Zlamparet GL, Zeng X, Li J (2017) Evaluating waste printed circuit boards recycling: opportunities and challenges, a mini review. Waste Manag Res 35:346–356

Yaashikaa PR, Priyanka B, Kumar PS, Karishma S, Jeevanantham S, Indraganti S (2022) A review on recent advancements in recovery of valuable and toxic metals from e-waste using bioleaching approach. Chemosphere 287:132230

Chen Z, Yang M, Shi Q, Kuang X, Jerry QH, Wang T (2019) Recycling waste circuit board efficiently and environmentally friendly through small-molecule assisted dissolution. Sci Rep 9:17902. https://doi.org/10.1038/S41598-019-54045-W

Wang Q, Zhang B, Yu S, **ong J, Yao Z, Hu B, Yan J (2020) Waste-printed circuit board recycling: focusing on preparing polymer composites and geopolymers. ACS Omega 5(16):17850–17856

Huang K, Guo J, Xu Z (2009) Recycling of waste printed circuit boards: a review of current technologies and treatment status in China. J Hazard Mater 164(2–3):399–408

Cucchiella F, D’adamo I, Lenny Koh SC, Rosa P (2015) Recycling of weees: an economic assessment of present and future e-waste streams. Renewable Sustain Energy Rev 51:263–272. https://doi.org/10.1016/J.Rser.2015.06.010

de Capitani (2009) Diagnóstico e tratamento da intoxicação por chumbo em crianças e adultos. Medicina 42(3):319–329

Birloaga I, de Michelis I, Ferella F, Buzatu M, Vegliò F (2013) Study on the influence of various factors in the hydrometallurgical processing of waste printed circuit boards for copper and gold recovery. Waste Manage 33:935–941

Sodha AB, Tipre DR, Dave SR (2020) Optimization of biohydrometallurgical batch reactor process for copper extraction and recovery from non-pulverized waste printed circuit boards. Hydrometallurgy 191:105170

Monneron-Enaud B, Wiche O, Schlömann M (2020) Biodismantling, a novel application of bioleaching in recycling of electronic wastes. Recycling 5:22. https://doi.org/10.3390/recycling5030022

Wang L, Li Q, Li Y, Sun X, Li J, Shen J, Han W, Wang L (2018) A Novel Approach for recovery of metals from waste printed circuit boards and simultaneous removal of iron from steel pickling waste liquor by two-step hydrometallurgical method. Waste Manage 71:411–419

Yken JV, Cheng KY, Boxall NJ, Nikoloski AN, Moheimani N, Valix M, Sahajwalla V, Kaksonen AH (2020) Potential of metals leaching from printed circuit boards with biological and chemical lixiviants. Hydrometallurgy 196:105433

Motaghed M, Mousavi SM, Rastegar SO, Shojaosadati SA (2014) Platinum and rhenium extraction from a spent refinery catalyst using Bacillus Megaterium as a cyanogenic bacterium. Statistical modeling and process optimization. Bioresource Technol 171:401–409. https://doi.org/10.1016/J.Biortech.2014.08.032

Liang G, Tang J, Liu W, Zhou Q (2013) Optimizing mixed culture of two acidophiles to improve copper recovery from printed circuit boards (PCBs). J Hazard Mater 250:238–245

Choi M-S, Cho K-S, Kim D-S, Kim D-J (2004) Microbial recovery of copper from printed circuit boards of waste computer by Acidithiobacillus Ferrooxidans. J Environ Sci Health Part A 39(11):1–10

Brandl H, Faramarzi MA (2006) Microbe-metal-interaction for the biotechnological treatment of metal-containing solid waste. China Particuol 4(2):93–97

Gu W, Bai J, Lu L, Zhuang X, Zhao J, Yuan W, Zhang C, Wang J (2019) Improved bioleaching efficiency of metals from waste printed circuit boards by mechanical activation. Waste Manag 98:21–28. https://doi.org/10.1016/j.wasman.2019.08.013

Dev S, Sachan A, Dehghani F, Ghosh T, Briggs A, Aggarwal S (2020) Mechanisms of biological recovery of rare-earth elements from industrial and electronic wastes: a review. Chem Eng J. https://doi.org/10.1016/j.cej.2020.124596

Boxall NJ, Cheng KY, Bruckard W, Kaksonen AH (2018) Application of indirect non-contact bioleaching for extracting metals from waste lithium-ion batteries. J Hazard Mater 360:504–511

Murugesan MP, Kannan K, Selvaganapathy T (2020) Bioleaching recovery of copper from printed circuit boards and optimization of various parameters using response surface methodology (RSM). Mater Today Proceedings 26(2):2720–2728

Kasper AC, Viet HM (2018) Gold recovery from printed circuit boards of mobile phones scraps using a leaching solution alterative to cyanide. Braz J Chem Eng 35:931–942

Fathollahzadeh H, Khaleque, H.N., Eksteen, J., Kaksonen, A.H., Watkin, E.L.J., (2019) Effect of glycine on bioleaching of rare earth elements from Western Australian monazite by heterotrophic and autotrophic microorganisms. Hydrometallurgy 189, 105137. Franke, D., Suponik.

**a MC, Wang YP, Peng TJ, Shen L, Yu RL, Liu YD, Chen M, Li JK, Wu XL, Zeng WM (2017) Recycling of metals from pretreated waste printed circuit boards effectively in stirred tank reactor by a moderately thermophilic culture. J Biosci Bioeng 123:714–721. https://doi.org/10.1016/j.jbiosc.2016.12.017

Hubau A et al (2018) Continuous production of a biogenic ferric iron lixiviant for the bioleaching of printed circuit boards (PCBs). Hydrometallurgy 180:180–191

D’Adamo I, Ferella F, Gastaldi M, Maggiore F, Rosa P, Terzi S (2019) Towards sustainable recycling processes: wasted printed circuit boards as a source of economic opportunities. Resour Conserv Recycl 149:455–467

Srivastava RR, Ilyas S, Kim H, Choi S, Trinh HB, Ghauri MA, Ilyas N (2020) Biotechnological recycling of critical metals from waste printed circuit boards. J Chem Technol Biotechnol 95:2796–2810

Faramarzi MA, Mogharabi-Manzaria MBH (2020) Bioleaching of metals from wastes and low-grade sources by HCN-forming microorganisms. Hydrometallurgy 191:105228

Tomska A, Wolny L (2008) Enhancement of biological wastewater treatment by magnetic field exposure. Desalination 222:368–373

Zieliński M, Rusanowska P, Dębowski M, Hajduk A (2018) Influence of static magnetic field on sludge properties. Sci Total Environ 625:738–742

Dias RM, Cardoso VL, de Resende MM (2016) Influence of magnetic field frequency generated by permanent magnets in mixed culture used for the treatment of effluent contaminated with chromium. Water Air Soil Pollut 227:305

Dias RM, da Costa EJX, Cardoso VL, De Resende MM (2020) Interference of a magnetic field generated by circular magnets in the retention of chromium by microbial cells and in the morphology of a mixed culture during the bio-removal of chromium from effluent. Chem Eng Process 154:108019

Garcia O Jr (1991) Isolation and purification of Thiobacillus ferrooxidans and Thiobacillus thiooxidans from some coal and uranium mines of Brazil. Rev Microbiol 22:1–6

Paulino LC, Bergamo RF, Mello MP, Garcia O Jr, Manfio GP, Ottoboni LMM (2001) Molecular characterization of Acidithiobacillus, ferrooxidans and A. thiooxidans strains isolated from mine wastes in Brazil. Antonie Van Leeuwenhoek 80:65–67

Dermou E, Velissariou A, Xenos D, Vayenas DV (2005) Biological chromium (VI) reduction using a trickling filter. J Hazardous Mater B126:78–85

**n B, Zhang D, Zhang X, **a Y, Wu F, Chen S, Li L (2009) Bioleaching mechanism of Co and Li from spent lithium-ion battery by the mixed culture of acidophilic sulfur-oxidizing and iron-oxidizing bacteria. Biores Technol 100(24):6163–6169

Dias RM, Silva JG, Cardoso VL, de Resende MM (2020) Removal and desorption of chromium in synthetic effluent by a mixed culture in a bioreactor with a magnetic field. J Environ Sci 91:151–159

APHA, Awwa & WEF. In Rice, E. W., Baird, R. B., Eaton, A. D. (ed) (2017) 23rd edn. American Water Works Association; American Public Works Association; Water Environment Federation, Washington, DC

Madigan, M.T. , Martinko, J.M., Dunlap, P.V., Clark , D. P., (2004) Brock Biology of Microorganisms. 12th Ed. - San Francisco, Calif.: Pearson/Benjamin Cummings.

ABNT (1987) Associação Brasileira de Normas Técnicas. NBR 9898: Preservação e Técnicas de Amostragem de Efluentes Líquidos e Corpos Receptores, Rio de Janeiro.

de Queiroz JRC, Marocho SS, Benetti P, Tango RN, Nogueira JL (2012) Métodos de caracterização de materiais para pesquisa em odontologia. Revistas Eletrônicas de Odontologia 17:1

Priya A, Hait S (2020) Biometallurgical recovery of metals from waste printed circuit boards using pure and mixed strains of Acidithiobacillus ferrooxidans and Acidiphilium, acidophilum. Process Saf Environ Prot 143:262–272

Gandolfi MG, Sauro S, Mannocci F, Watson TF, Zanna S, Capoferri M et al (2007) New tetrasilicate cements as retrograde filling material: an in vitro study on fluid penetration. J Endod 33:742–745

Ye M, Liang J, Liao X, Li L, Feng X, Zhou WQS, Sun S (2021) Bioleaching for detoxification of waste flotation tailings: Relationship between EPS substances and bioleaching behavior. J Environ Manage 111795:0301–4797

Utimura S, Arevalo SJ, Rosario CGA, Aguilar MQ, Tenório JAS, Espinosa DCR (2019) Bioleaching of metal from waste using a native strain of Acidithiobacillus isolate from a coal mine drainage. Can J Chem Eng 97(11):2920–2927

Lebkowska M, Rutkowska-Narozniak A, Pajor E, Pochanke Z (2011) Effect of a static magnetic field on formaldehyde biodegradation in wastewater by activated sludge. Biores Technol 102:8777–8782

Maoyou Y, Yan P, Sun S, Han D, **ao X, Zheng L, Huang S, Chen Y, Zhuang S (2017) Bioleaching combined brine leaching of heavy metals from lead-zinc mine tailings: transformations during the leaching process. Chemosphere 168:1115–1125

Rouchalova D, Rouchalova K, Janakova I, Cablik V, Janstova S (2020) Bioleaching of Iron, Copper, Lead, And Zinc From The Sludge Mining Sediment At Diferent Particle Sizes, Ph, And Pulp Density Using Acidithiobacillus Ferrooxidans. Minerals 10:1013. https://doi.org/10.3390/Min10111013

Abraham, J.; Chatterjee, A.; Sharma, J. (2020). Isolation and Characterization of a New Bacillus licheniformis Strain for Bioleaching Heavy Metals, J Appl Biotechnol Rep.7(3):139–144.

Ji Y, Wang Y, Sun J, Yan T, Li J, Zhao T, Yin X, Sun C (2010) (2010) Enhancement of biological treatment of wastewater by magnetic field. Biores Technol 101:8535–8540

Acknowledgements

We thank the Federal University of Uberlândia, Faculty of Chemical Engineering, the National Council for Scientific and Technological Development—Process: 424724/2018-9 (CNPq-Brazil), Coordination for the Improvement of Higher Education Personnel (CAPES-Brazil), and Foundation for Research Support of the State of Minas Gerais for promoting research.

Author information

Authors and Affiliations

Contributions

The authors, JGS and RMD, were responsible for writing the Experimental part of the manuscript and writing it. Professors VLC and MMR guided the experiments and corrected the manuscript's text.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no potential conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Silva, J.G., da Silva, M.T., Dias, R.M. et al. Biolixiviation of Metals from Computer Printed Circuit Boards by Acidithiobacillus ferrooxidans and Bioremoval of Metals by Mixed Culture Subjected to a Magnetic Field. Curr Microbiol 80, 197 (2023). https://doi.org/10.1007/s00284-023-03307-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00284-023-03307-y