Abstract

Welan gum, a natural polysaccharide produced by Sphingomonas sp. ATCC 31555, has attracted considerable attention in the scientific community due to its desirable properties. However, challenges, such as high viscosity, residual bacterial cells, carotenoids, and protein complexation, hinder the widespread application of welan gum. In this study, we established a method for the extraction and purification of welan gum using a synergistic approach with lysozyme and alkaline protease. Lysozyme hydrolysis conditions were optimized by applying response surface methodology, and the best results for bacterial cell removal were achieved at 11 000 U/g, 44 °C, and pH 9 after 3 h of treatment. Subsequently, we evaluated protein hydrolysis through computer simulation and identified alkaline protease as the most suitable enzyme. Through experimental investigations, we found that the optimal conditions for alkaline protease hydrolysis were 7500 U/g, 50 °C, pH 10, and 600 rpm. These conditions resulted in a sugar recovery rate of 76.1%, carotenoid removal rate of 89.5%, bacterial removal rate of 95.2%, and protein removal rate of 87.3% after 3 h of hydrolysis. The purified welan gum exhibited high transparency and purity. Structural characterization and antioxidant activity evaluation revealed that enzymatically purified welan gum has potential application prospects. Our study provides valuable insights into the optimal method for the enzymatic extraction and purification of welan gum. Such a method is conducive to the development of the multiple potential applications of welan gum.

Key points

• A novel process for the synergistic purification of welan gum using lysozyme and alkaline protease was established.

• In silico virtual digestion was employed to select the purification enzyme.

• Welan gum with high transparency and purity was obtained.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Welan gum, a natural polysaccharide produced by Sphingomonas sp. ATCC 31555, belongs to the sphingan family along with xanthan gum and gellan gum. Its structure is composed of repeating tetrasaccharide backbone, consisting of D-glucose, D-glucuronic acid, D-glucose, and L-rhamnose, with side chains containing L-rhamnose or L-mannose. Additionally, approximately half of the tetrasaccharide backbone also carry acetyl and glyceroyl groups (Kaur et al. 2014).This unique structural composition imparts non-gelling properties to welan gum, setting it apart from other sphingans (Wen et al. 2021). Furthermore, welan gum exhibits remarkable thermal stability in aqueous solutions, retaining its properties even at temperatures as high as 150 °C. It also demonstrates acid and alkali stability, maintaining viscosity under extreme pH conditions (pH 2 to 12). These outstanding characteristics have led to the extensive use of welan gum in improving building materials such as cement and concrete, as well as in applications within the household chemicals and petroleum extraction industries. In recent years, research has explored the potential application of welan gum in areas like food, cosmetics, and biodegradable materials. However, the challenges of extraction and purification, including their complexity, low efficiency, and high costs, have significantly restricted its expansion into other domains. Sphingomonas (Carmona et al. 2023; Baudoin et al. 2023; Lu et al. 2023; Nsengiyumva and Alexandridis 2022). Challenges, such as high viscosity, residual bacterial cells, carotenoids, and protein complexation, pose critical obstacles to the purification and extraction of welan gum, making the purification of the final product difficult; in particular, these challenges complicate welan gum purification and extraction in terms of impurity removal, product purification, and drying, which account for approximately 50% of the total production costs of welan gum (Kaur et al. 2014). Traditional extraction and purification methods involve multiple dilutions and the use of large quantities of organic solvents and chemical reagents (Roca et al. 2015). However, these methods result in the coprecipitation of large molecular impurities, forming irreversible aggregates. Lopes et al. subjected diluted, non-heat-treated fermentation broth to NaOH treatment followed by filtration through a 0.2 µm membrane to avoid organic reagent precipitation and welan gum coagulation caused by heating and sterilization (Lopes et al. 1994). However, this method showed limited effectiveness in removing proteins and carotenoid. Other promising techniques, such as size-exclusion chromatography and ion-exchange chromatography, have been partially applied in laboratory-scale preparation studies on medium-molecular-weight welan gum but have not yet been developed for industrial production mainly due to the properties and costs associated with welan gum (Zhao et al. 2022). In addition, the molecular weights of some low-to-medium-molecular-weight welan gums produced through cleaning with cheap substrates are close to those of proteins, making protein separation difficult. Carotenoid removal has also been a recent focus of research. For example, Zhao et al. disrupted the sorting enzyme gene (srtW) in Sphingomonas sp. ATCC 31555 strain to modify cell wall capsule morphology; they obtained welan gum with high transparency, albeit with a drastic decrease in molecular weight (Zhao et al. 2021). Similarly, Zhang et al. inserted the Vitreoscilla hemoglobin gene with the lacZ promoter into the carotenoid hydroxylase gene region of the ATCC 31555 chromosome to obtain an industrial strain devoid of carotenoids (Zhang et al. 2016). Thus, the quest for an efficient, environmentally friendly, and cost-effective extraction and purification method remains a focal point of current research.

In silico virtual digestion is an effective method for predicting the outcomes of protein hydrolysis using multiple target enzymes. Particularly, when considering the differences in peptide structure, molecular weight, and amino acid composition resulting from the substrate specificity of different enzymes, this approach provides valuable insights. It aids in optimizing the engineering design of hydrolysis processes, reducing laboratory experimental costs, and decreasing the demand for costly reagents and biological materials, ultimately enhancing the economic efficiency of research and production. Currently, various servers such as BIOPEP, PeptideCutter, and EnzymePredictor are being utilized to predict potential protein hydrolysis cleavage sites (Mooney et al. 2013; Hsieh et al. 2016; Tu et al. 2018). For instance, Udenigwe conducted computer-simulated protein hydrolysis, using gastric protease and thermophilic bacterial protease to digest glutathione, with the aim of adding value to by-products in functional food formulations (Udenigwe and Aluko 2012). Similarly, ExPASy-PeptideCutter has been employed for computer-assisted digestion of 15 common food proteins, utilizing both single enzymes and multiple enzymes (Cu et al. 2011). By comparing the differences in active peptides and inhibitory peptides generated after hydrolysis of these food proteins, these tools provide valuable information. However, it is important to note that most current research focuses on high-efficiency and high-activity products obtained after virtual digestion, rather than considering how to remove these products. Applying computer virtual digestion in purification research represents a novel scientific extension worthy of further exploration.

In this study, we aim to optimize the high-quality extraction of welan gum from fermentation broth through a synergistic approach with lysozyme and alkaline protease. We optimized lysozyme hydrolysis conditions by using response surface methodology (RSM). Additionally, we performed the computer simulation of protein hydrolysis by alkaline protease and determined the optimal process conditions through experimental validation to obtain welan gum with high transparency and purity. Finally, through structural characterization and antioxidant activity evaluation, we revealed the potential applications of the purified welan gum as a food additive and in cosmetics.

Materials and methods

Materials

Sphingomonas sp. ATCC 31555 was provided by the School of Biotechnology, Jiangnan University. Lysozyme (20 U/mg) was procured from Shanghai Brilliant Chemical Technology Co., Ltd. Each unit of lysozyme activity denotes the enzyme’s capacity to reduce the initial optical density of a 1 ml suspension of Micrococcus luteus cells at 25 °C and pH 7.0 from 0.750 to 0.001 per min, using a 10-mm path length. Alkaline protease (200 U/mg) was sourced from China National Pharmaceutical Group Chemical Reagent Co., Ltd. Each unit of alkaline protease activity signifies the enzyme’s ability to hydrolyze casein and generate color equivalent to 1.0 µmole (181 µg) of tyrosine under pH 7.5 and 37 °C conditions, with the Folin-Ciocalteu reagent employed for color development. The kits required for this experiment were all purchased from Bei**g Solarbio Science & Technology Co., Ltd.

Preparation of welan gum

Sphingomonas sp. ATCC 31555 was cultivated in a 250 mL seed medium at 30 °C and 220 rpm for 16 h. Subsequently, it was inoculated with a 10% volume ratio into a 1 L fermentation medium and incubated at 30 °C and 220 rpm for 108 h to yield the welan gum fermentation broth. The seed medium was composed of 20 g/L sucrose, 3 g/L yeast extract, 3 g/L tryptone, and 5 g/L fish peptone and had a pH of 7.0. Sterilization was performed at 115 °C for 20 min. The fermentation medium was composed of 40 g/L glycerol, 2 g/L beef extract, 0.6 g/L KH2PO4, and 0.2 g/L MgSO4–7H2O and was sterilized at 120 °C for 20 min.

Determination of bacterial cell count

Bacterial cell count was determined by using the Elson–Morgan method (Simmons 1962), which relies on the measurement of N-acetylglucosamine in the cell wall acid of a strain, thereby eliminating interference from welan gum, proteins, and other factors. The specific procedure was as follows: A thoroughly mixed sample of the pre-enzymatic hydrolysis fermentation broth was collected and concentrated under reduced pressure then dried. The post-enzymatic hydrolysis fermentation broth was centrifuged at 12,000 rpm for 15 min at room temperature. The precipitate was collected and washed three times with physiological saline. It was then placed in 12 mol/L concentrated HCl at room temperature for 24 h. The concentration of HCl was adjusted to 8.5 mol/L, and the sample was digested in a boiling water bath for 45 min. After the sample was cooled, its pH was adjusted to neutral by using NaOH solution. Then, it was made up to a final volume of 100 mL. For analysis, 1 mL of the sample was mixed with 1 mL of distilled water and transferred to a 10 mL stoppered colorimetric tube. The mixture was thoroughly mixed with 1 mL of acetylacetone and subsequently heated in a boiling water bath for 25 min. After being cooled, the mixture was added with 6 mL of anhydrous ethanol and 1 mL of dimethylaminobenzaldehyde and mixed. The mixture was then incubated in a 75 °C water bath for 6 h. It was cooled to room temperature and its absorbance was measured at a wavelength of 525 nm. The precipitate collected from the original fermentation broth served as the control group. The formula for determining the bacterial removal rate (BRR) is \(\text{BRR(\%)}=\frac{{A}_{sample}}{{A}_{control}}\times 100\%\).

Experimental design and RSM optimization

The key variables selected for optimization through single-factor analysis were lysozyme hydrolysis time (X1), temperature (X2), and pH (X3). BRR was chosen as the response variable (Y). As shown in Table 1, 17 experimental runs were designed by using the Box–Behnken Design in Design-Expert 10.0.7 software in consideration of the three independent variables at three different levels. The BRR was measured three times for each run, and the results within the range of standard deviation were recorded. The experimental data on the response variables were fitted by using the second-order polynomial model.

Where Y represents BRR; β0 is the intercept coefficient; βi, βii, and βij are the linear, quadratic, and interaction coefficients, respectively; and Xi and Xj are the independent variables (i ≠ j).

Bioinformatics analysis

The UniProt database was searched by using the species defined as Sphingomonas sp. WG. This species shows high similarity with the ATCC 31555 strain and has a high level of annotation (Wu et al. 2017). Information, such as entry name, sequence length, and mass spectrometry, was extracted from the search results.

Skyline software (MacLean et al. 2010) was used for in silico digestion. In the peptide settings, enzyme digestion was customized as alkaline protease [FLWY|P] or alternatively, the preset option of trypsin [KR|P] was selected. The maximum number of missed cleavage sites was set to 1. The filter settings included a minimum length (M) of 2 and a maximum length (X) of 200. N-terminal amino acids were not excluded (N). The peptide precursor ion charge was set as 2+, and modifications, such as Cys, Met, and His, were allowed. The structural modifications selected were carbamidomethyl c and oxidation (M).

Determination of the purification index

The postdigestion fermentation broth was centrifuged, and the resulting supernatant was mixed with twice the volume of anhydrous ethanol and stirred for 20 min. The mixture was then allowed to settle at 4 °C for 12 h. The upper white flocculent precipitate was dissolved in water and centrifuged at 12,000 rpm for 10 min. The supernatant was transferred to a Pellicon® Capsule with Ultracel® Membrane (Merck KGaA, Darmstadt, Germany) with a molecular weight cutoff of 30 kDa for ultrafiltration. The feed flow rate was set to 4 L/min with a forward transmembrane pressure below 50 psi. Ultrafiltration was repeated multiple times. Subsequently, the concentrated filtrate was freeze-dried to obtain a powder. The carotenoid removal rate (CRR), sugar recovery rate (SRR), protein removal rate (PRR), and BRR were determined by using the freeze-dried powder. The original fermentation broth was used as the control group for all measurements.

PRR: Protein content was determined by using the Bradford method with 20–100 µg/mL bovine serum albumin as the standard (Bradford 1976). Absorbance was measured at 595 nm. The regression equation was A = 0.0037C + 0.0259, r2 = 0.9901. PRR was calculated by using the formula \(\text{PRR(\%)}=\frac{{C}_{sample}}{{C}_{control}}\times 100\%\).

SRR: Polysaccharide content was measured by using the phenol–sulfuric acid method (Masuko et al. 2005). Glucose in the concentration range of 10–60 µg/mL was used as the standard, and absorbance was measured. The regression equation obtained was A = 0.016C − 0.0034 with r2 = 0.9969. SRR was calculated by using the formula \(\text{SRR(\%)}=\frac{{C}_{sample}}{{C}_{control}}\times 100\%\).

CRR: A plant carotenoid content assay kit was used to determine carotenoid content by using a microplate reader at a wavelength of 440 nm. CRR was calculated by using the formula \(\text{CRR(\%)}=\frac{{A}_{sample}}{{A}_{control}}\times 100\%\).

BRR: Bacterial cell quantification was performed by following the method described in the “Bioinformatics analysis” section.

Analysis of monosaccharide composition

A total of 2 mg of the sample was added to 2 mL of trifluoroacetic acid (TFA) solution with a concentration of 4 mol/L. The mixture was hydrolyzed at 110 °C for 4 h then cooled to room temperature. Subsequently, 4 mL of deionized water was added. The solution was vacuum-dried in the test tube, added with 3 mL of methanol, then repeatedly vacuum dried five times to ensure the complete removal of residual TFA. The resulting precipitate was dissolved in 2 mL of ultrapure water and centrifuged at 12,000 rpm for 10 min. The solution was then diluted and analyzed by using a Dionex ion chromatograph (USA) under the following detection conditions: CarboPac PA20 anion exchange analytical column (150 mm × 3 mm); reference electrode, Ag/AgCl; detection, pulsed amperometric detector; flow rate, 0.45 mL/min; elution time, 25 min. A ternary gradient elution system was used, where flow phase A was 200 mM NaOH, B was 700 mM NaOAc, and C was deionized water. The elution program (A% B% C%) was 0 min, 50, 1, 49; 6 min, 50, 4, 46; 15 min, 50, 20, 30; 20 min, 50, 40, 10; and 25 min, 100, 0, 0.

Determination of molecular weight distribution

A total of 2 g of the sample was dissolved in 1 L of ultrapure water and homogenized by using a homogenizer. Then, 1 mL of the solution was transferred to a vial and analyzed by using a high-performance gel permeation chromatography system (Agilent Technologies Inc., USA) coupled with a DAWN HELEOS 8 + multiangle laser light scattering detector and an Optilab® dRI detector to determine the molecular weight and uniformity of welan gum. The mobile phase consisted of ultrapure water containing 0.2 M NaNO3 and 0.01 M NaH2PO4. Analysis was performed by utilizing a gel column (PL aquagel-OH MIXED-H 8 µm, 7.5 × 300 mm, Agilent) at a flow rate of 0.5 mL/min, an injection volume of 200 µL, a temperature of 50 °C, and a wavelength of 660 nm. Data acquisition and calculation were performed by applying Astra software (Wyatt).

Fourier-transform infrared spectral analysis

The functional groups of welan gum before and after enzymatic purification were analyzed by using an iS20 Fourier-transform infrared (FTIR) spectrometer (Thermo Nicolet, Madison, WI, USA). A total of 3 mg of freeze-dried powder was used for FTIR measurements in the mid-infrared range of 400–4000 cm−1, and the data were analyzed by using Omnic software.

Analysis of antioxidant activity

Activity evaluation included assays for ABTS, DPPH, superoxide anion radical, and hydroxyl radical scavenging. Welan gum purified through different methods was dissolved at different concentrations and assessed by using established protocols. Ascorbic acid was used as a positive control, and deionized water served as the blank in all experiments. The specific calculation formula for scavenging capacities is

Statistical analysis

Each test was conducted in triplicate, and the results were expressed as mean ± standard deviation. Statistical analysis was performed by using SPSS Statistics 22.0 software. One-way analysis of variance (ANOVA) and Duncan’s tests were employed with a significance level of 0.05 to determine any significant differences among groups.

Results

Effect of lysozyme on BRR

During welan gum production, the viscosity and turbidity of the fermentation broth increase, complicating the complete separation of welan gum from bacterial cells. The bacterial cell wall skeleton is primarily composed of peptidoglycan, and lysozyme can hydrolyze the β-1,4-glycosidic bonds between N-acetyl muramic acid and N-acetyl glucosamine. Sphingomonas sp., the welan gum-producing bacterium, is a Gram-negative bacterium. However, studies have suggested that it possesses eukaryotic evolution genes, and its cell wall accounts for 10–25% of its cell dry weight. In particular, the unique glycolipid structure of the cell membrane of Sphingomonas sp. is distinct from that of the cell membrane of other Gram-negative bacteria (Kawasaki et al. 1994).

Lysozyme processing time and enzyme concentration significantly influence the purification of welan gum. Figure 1a shows that the BRR of the fermentation broth increases as the incubation time increases within the first 3 h. After 3 h of incubation, BRR reaches 73.5% and stabilizes. Figure 1b illustrates that BRR increases with increasing enzyme concentration, reaching a maximum of 74.4% at an enzyme concentration of 10,000 U/L. However, BRR slightly decreases when the enzyme concentration is increased to 12,000 U/L.

The pH value and temperature of the treated solution are also important factors affecting the purification of welan gum. Lysozyme exhibits a wide pH tolerance range and strong thermal stability. It retains its enzymatic activity after treatment at 100 °C for 1 min over the pH range of 4–7 (Wu et al. 2019). It can withstand being heated at 100 °C for 45 min at pH 3. It exhibits strong thermal stability under acidic conditions but poor thermal stability under alkaline conditions. Figure 1c shows that the purification rate of welan gum gradually increases as the pH of the treated solution increases from 4 to 9. The highest purification rate of welan gum is achieved at pH 7 and is 76.0%. Overall, lysozyme exhibits higher BRR under slightly alkaline conditions than under acidic conditions likely because the low viscosity of welan gum in alkaline environments increases the probability of contact between the enzyme and bacterial cells. Under neutral conditions (pH = 7), the fermentation broth incubated at 30–35 °C shows a significantly low BRR of only approximately 20%. However, at 45 °C, the maximum observed BRR is 64.9%. Further increasing the temperature to 55 °C results in a slight decrease in BRR.

Results of response surface optimization

The experimental design and results of the response surface test are shown in Table 1. We conducted 17 experiments to optimize the three individual parameters in the Box–Behnken Design. Table 1 provides the BRR (dependent variable) of each run in the experimental design. Experiment 16 achieved the maximum BRR under the conditions of the enzyme concentration of 7250 U/L, extraction temperature of 45 °C, and pH of 7.0. Experiment 9 resulted in the lowest BRR of 38.7% under the conditions of the enzyme concentration of 2500 U/L, extraction temperature of 35 °C, and pH of 7.0.

The regression equation for BRR was obtained through regression fitting using Design Expert 10.0.7 statistical software.

Pareto ANOVA was performed on the regression equation of the BRR. Table 2 shows that the model is highly significant (P < 0.001) and that the lack-of-fit term is not significant (P = 0.126 > 0.05). This result indicates a good correlation between predicted and experimental values, a good fit, and small error. Therefore, the relationship of the three factors with BRR can be feasibly represented by the regression equation mentioned above. The coefficient of determination (R2) for the model is 0.9900, and the adjusted coefficient of determination (Radj2) is 0.9772. The model established through the experiments can account for 88.0% of the variation in responses. The results of the significance analysis show that the first-order terms X1, X2, and X3 and the second-order terms X12 and X22 have a highly significant effect on the BRR (P < 0.001) and that the second-order terms X2X3 and X1X3 have a significant effect on the BRR (P < 0.01). Furthermore, by comparing the F-values of the model factors, we found that the effects of the factors on the experimental results follow the order of A > B > C (enzyme concentration > temperature > pH).

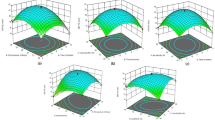

The response surface analysis is shown in Fig. 2a and b. As indicated by its steep curve, enzyme concentration has a significant effect on BRR. BRR increases initially with temperature then decreases. Increasing the temperature enhances mass transfer dynamics, facilitating the interaction between bacteria and enzymes. However, when the temperature reaches a certain level, it may exceed the optimal temperature for the enzyme, leading to enzyme inactivation and a gradual decrease in BRR. Notably, the enzyme exhibits a high BRR at pH 9, which is inconsistent with the optimal pH reported in the literature (Wu et al. 2019). The main reason and possibly the best explanation for this discrepancy is that the decrease in the viscosity of welan gum under alkaline conditions increases the contact area with the enzyme (More et al. 2021). The contour plots of enzyme concentration and temperature and temperature and pH are elliptical, indicating a significant interaction effect. This finding is consistent with the ANOVA results.

We conducted three validation experiments to test the applicability of the optimal variables of bacterial cell removal and thus validate the adequacy of the equation model. In consideration of convenience, we modified the experimental conditions to the enzyme concentration of 11 000 U/g, temperature of 44.0, pH of 9.0, and duration of 3 h. The validation experiment yields an average BRR of 83.5%.

Computer-aided purification of welan gum through virtual digestion

The welan gum fermentation broth mainly contains the following types of proteins: (1) extracellular proteins: proteins secreted into the extracellular environment, such as enzymes, antibodies, and hormones; (2) intracellular proteins: proteins present inside cells, including enzymes, metabolic products, and protein degradation products; (3) structural proteins: proteins that constitute the cell skeleton and cell wall, such as cytoskeletal proteins and cell wall component proteins; (4) residual proteins from the culture medium: proteins that are used as nitrogen sources in the culture medium but are not fully consumed.

UniProt is a comprehensive protein database that allows the targeted retrieval of the protein information of a specific species (Consortium 2015). In this study, we explored the protein composition of Sphingomonas sp. WG because previous literature indicated a high homology between WG and ATCC strains. This information contributes to understanding the complexity of proteins in welan gum fermentation broth. Based on this data, we used the Skyline tool to guide the subsequent separation and purification of welan gum. Skyline, an open-source software for proteomic research, is based on specific enzyme cleavage specificity knowledge modules (MacLean et al. 2010). It allows users to customize enzyme hydrolysis types, making it a powerful tool for predicting the release of amino acids or peptides from specific protein substrates. Specifically, this study explored a method for analyzing complex protein complexes in hydrolyzed welan gum fermentation broth through the following steps: (a) searching the species of Sphingomonas sp. WG in the UniProt database and categorizing and annotating the molecular weight distribution of the mined protein database results, (b) conducting virtual digestion analysis of the proteins from (a) after setting the cleavage specificity parameters for two candidate enzymes using the Skyline tool, (c) categorizing and annotating the molecular weight distribution of peptides generated by virtual digestion with different candidate enzymes and comparing the purification effectiveness of these enzymes.

A total of 3630 proteins, including 1118 and 163 proteins with sequence lengths exceeding 600 and 800 amino acids, respectively, were retrieved from the database. Figure 3a shows the distribution of protein molecular weights in the database. Proteins with molecular weights of 30–50 kDa account for the highest proportion or approximately one-third of the total proteins (1068 proteins). Proteins with molecular weights of 50–100 and above 100 kDa account for approximately half of the total proteins (725 proteins). The proteins and welan gum have similar molecular weights. The commonly used direct water–alcohol precipitation method in the industry causes all large molecules to precipitate. This situation is clearly unsuitable for welan gum purification.

Analysis of computer-aided enzymatic digestion for welan gum purification. a Protein molecular weight distribution of Sphingomonas sp. WG in the UniProt database. b Peptide molecular weight distribution obtained after virtual digestion with alkaline protease. c Peptide molecular weight distribution obtained after virtual digestion with pancreatic protease

In this study, we performed the virtual digestion of the 3630 proteins of Sphingomonas sp. WG on the basis of Skyline by using the commonly used purification enzymes trypsin and alkaline protease. The digestion was used to predict the composition of protein products after enzymatic hydrolysis, thus providing an efficient strategy for guiding protein separation and purification. Figure 3b and c shows the virtual digestion results for trypsin and alkaline protease, respectively, in terms of the distribution of peptide molecular weights. Trypsin and alkaline protease digestion generated 209,459 and 383,287 peptides, respectively. The top four molecular weight distributions of peptides from trypsin digestion are 1–1.5 (31.7%), 0.5–1 (23.8%), 2–2.25 (13.9%), and 0–0.5 kDa (13.9%). Alkaline protease results in a greater degree of molecular weight degradation than trypsin. A total of 51.4% of the peptides produced through alkaline protease digestion have molecular weights of less than 1 kDa, including 0–0.5 (20.5%) and 0.5–1 kDa (30.9%). Alkaline protease has improved the digestion capacity for the large peptide range of 2.5–3 kDa by 59.6% relative to trypsin. It has a wide range of cleavage sites that allow for specific recognition and cleavage. It degrades proteins in the fermentation broth into peptides with improved water solubility, reducing the probability that they will precipitate during low-concentration ethanol precipitation and improving separation. Furthermore, it can further degrade redundant lysozyme and residual bacterial cells. Therefore, alkaline protease is a suitable choice.

Comprehensive effect of alkaline protease on welan gum purification

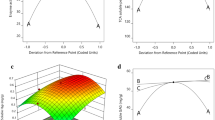

We conducted a series of experiments to investigate the effect of alkaline protease on sugar recovery, carotenoid removal, bacterial cell removal, and protein removal to assess the comprehensive effects of alkaline protease on welan gum purification. We optimized the enzymatic hydrolysis conditions accordingly. First, we compared different enzyme concentrations ranging from 2500 to 12,500 U/g. Figure 5a shows that a high overall BRR is achieved through enzymatic hydrolysis, alcohol precipitation, and ultrafiltration. Figure 4a and c illustrates that pH and temperature significantly influence welan gum extraction. Previous studies have suggested that welan gum exhibits good fluidity under alkaline conditions, thus promoting sufficient contact between the enzyme and substrate. Favorable protein removal and SRR are observed at a certain pH range and 45°–60 ℃. Specifically, the pH of 10 and temperature of 55 ℃ appear to be the most suitable conditions under which alkaline protease demonstrates superior efficacy with a PRR of 85.0%. However, an excessively low enzyme concentration leads to excessive protein–polysaccharide crosslinking, making removing proteins through ultrafiltration difficult. An excessively high enzyme concentration results in the generation of protein residues that negatively affect protein removal. In consideration of the comprehensive factors, an enzyme concentration of 7500 U/g yields favorable purification results with the SRR of 62.1%, CRR of 80.5%, BRR of 93.3%, and PRR of 78.6%. Subsequently, we investigated the influence of stirring speed as shown in Fig. 4d. We determined 600 rpm as the optimal stirring speed. The SRR of 76.1%, CRR of 89.5%, BRR of 95.2%, and PRR of 87.3% are obtained at this stirring speed.

Establishment of the purification process

By optimizing the aforementioned conditions, we established a process for the purification of welan gum through enzymatic hydrolysis as shown in Fig. 5a. The specific steps are illustrated below and were compared with other purification methods reported in the literature. The industrially used water extraction–alcohol precipitation–drying method, the Sevage method that is commonly used in laboratories, and the enzymatic hydrolysis method established in this study were compared as shown in Fig. 5b. At the same concentration, the transparency of the product obtained through enzymatic hydrolysis is significantly higher than that of the products of methods A and B. The solid powder obtained through enzymatic hydrolysis is light yellow, indicating that enzymatic hydrolysis has removed a greater portion of carotenoids compared with the Sevage method. Transparency is an important characteristic of polysaccharide samples within the visible light range, and high transparency is a necessary requirement in the fields of chemical engineering and food. At the same concentration, the dual-enzyme purification method has significantly improved the transparency of the welan gum samples compared with the other methods. The transmittance of the purified welan gum at 420 nm can reach 88.2%, which is highly consistent with the previously mentioned removal rate of carotenoids. The transmittance at 620 nm of the purified gum is 99.2%, which has improved by 34.9% compared with that of the unpurified welan gum and is 20.0% higher than that of the gum purified through the Sevage method (Table 3). This finding reflects the effectiveness of the combined use of lysozyme and alkaline protease in improving the removal of bacterial cells.

The Sevage and enzymatic methods have reduced viscosity by a certain degree; this effect is closely related to the removal of proteins (Zhao et al. 2021). Our enzymatic hydrolysis method demonstrates excellent performance in improving the transparency of polysaccharide samples without significantly reducing viscosity. Therefore, this purification method may be a suitable choice for applications, such as cosmetics and food additives.

Infrared spectrum and chemical composition of welan gum

FTIR spectroscopy is an effective method for the qualitative analysis of polysaccharide functional groups. In Fig. 6a, the peaks at 3319.30, 1722.82, 1602.95, and 1375.63 cm−1 indicate the presence of hydroxyl, acetyl, and carboxyl groups in welan gum. The bands observed at 1018.40 and 1230.53 cm−1 in the FTIR spectrum are attributed to the stretching vibrations of the C–O–C glycosidic bond and C–O–H bond in the rhamnose unit, respectively (Xu et al. 2017). The absorption peak at 2932.63 cm−1 is attributed to the C-H stretching vibrations of CH3, CH2, and CH groups. All of these are characteristic absorption peaks of sugars. Additionally, the absorption peaks at 808.76 and 1018.40 cm−1 suggest the presence of α- and β-glycosidic bonds, respectively. This finding is consistent with previous results showing that in welan gum, the main chain is linked by β-1,4-glycosidic bonds and is connected to side-chain groups via α-1,3-glycosidic bonds (Wei et al. 2022). This finding indicates that mannose units are present in the side chain of welan gum. The consistency among peak positions in the infrared spectra of welan gum samples obtained through different purification methods indicates that the gums have consistent molecular bond types.

Figure 6b displays the monosaccharide composition of the welan gum produced by Sphingomonas sp. ATCC 31555. In agreement with the previous reports, this gum consists of mannose, rhamnose, glucuronic acid, and glucose with molar ratios of 1:3.9:1.29:4.12. Overall, both purification methods have a minimal effect on the structure of welan gum.

Analysis of molecular weight distribution

In contrast to the Sevage method, enzymatic hydrolysis with alkaline protease removed a portion of closely sized peptides, resulting in the convergent peak shape of molecular weight distribution as observed in the MALS and RIU results presented in Fig. 6c. Although enzymatic hydrolysis purification is beneficial for improving the polymerization degree and uniformity of the molecular weight distribution of welan gum, it has a relatively minor influence on size. The Sevage and enzymatic purification methods provide Mw values of 1.090 × 105 and 1.129 × 105 g/mol, respectively, and Mn values of 5.906 × 104 and 7.150 × 104 g/mol, respectively, without significant differences. The analysis of the uniformity of molecular weight distribution reveals that compared with the Sevage method, enzymatic purification has decreased the Mw/Mn and Mz/Mn values of welan gum to 1.579 and 2.075, respectively. This finding indicates that the molecular weight distribution range of purified welan gum has narrowed and that the uniformity of molecular weight distribution has increased. The changes in the size of welan gum before and after purification can be determined by calculating the rn, rw, and rz parameters. The results show that the rn, rw, and rz parameters of the welan gum subjected to enzymatic purification have slightly increased to 103.2, 127.4, and 148.8 nm, respectively, and are 8.5%, 9.2%, and 4.8% greater than those of the welan gum treated through the Sevage method. In summary, enzymatic purification results in minor changes in the size and molecular weight of welan gum but can achieve a higher level of uniformity in molecular weight distribution than the Sevage method.

Antioxidant potential of welan gum

The investigation of antioxidants is currently a prominent topic in the biomedical and health fields. The excessive generation of reactive oxygen species causes damage to cellular components and leads to adverse effects on the human body. Therefore, the search for environmentally friendly and efficient antioxidants has become a focus of scientists’ attention (Andrew and Jayaraman 2020). In this context, naturally derived bioactive polysaccharides have been widely studied due to their excellent radical-scavenging activities. Welan gum, as a natural polysaccharide rich in aldehyde and carboxyl groups, has the potential to be a novel natural antioxidant (Li et al. 2022; Zhu et al. 2014).

In this study, we evaluated the antioxidant activity of welan gum and assessed its radical scavenging capacity by using indicators, such as ABTS, hydroxyl radicals, and DPPH. Additionally, we compared the welan gum purified through enzymatic hydrolysis with samples purified by using the Sevage method. Consistent with previous reports (Zhao et al. 2021), our study found a significant enhancement in the ability of welan gum to scavenge hydroxyl radicals with the increase in concentration. Figure 7a shows that the welan gum samples treated with enzymes exhibit higher hydroxyl radical scavenging capacity than those subjected to the Sevage method. At 0.2 g/L, the scavenging capacity has already reached 42.8%. In particular, at the highest concentration of 1 g/L, the welan gum obtained through the enzymatic method achieves the scavenging activity of 68.12%, which surpasses the scavenging activity of the welan gum processed through the Sevage method by 13.73%. This finding indicates that the enzymatic method has a significant effect on removing hydroxyl radicals, providing welan gum with increased antioxidant performance.

Evaluation of antioxidant activity of welan gum under different purification methods. The data represent the average of three separate experiments, and error bars represent standard deviations. a Hydroxyl radical scavenging capacity. b DPPH radical scavenging capacity. c ABTS radical scavenging capacity. d Superoxide anion radical scavenging capacity

Notably, the welan gum samples treated with enzymes have high ABTS and DPPH radical scavenging capacities. Figure 6b and c shows that within the concentration range of 0.2–3 g/L, the scavenging capacity of the gums increases from 11.12 to 23.19%. Furthermore, in the DPPH scavenging assay, the welan gum samples treated with enzymes demonstrate high scavenging activity at different concentrations. The enzyme sample treated with the lowest concentration of 0.2 g/L has a scavenging activity of 12.95%, whereas that treated with the highest concentration of 1.0 g/L presents a scavenging activity of 29.35%. This finding indicates that the enzyme-treated welan gum samples purified through the dual-enzyme method possess high antioxidant activity and that their scavenging capacity increases with concentration. Additionally, previous studies have indicated that the scavenging effect of antioxidants on DPPH radicals is mainly achieved through their proton-donating ability (Li et al. 2022). This finding suggests that the antioxidants in welan gum samples can provide protons to scavenge DPPH radicals. Thus, welan gum demonstrates excellent antioxidant capacity.

In summary, the welan gum samples treated with enzymes exhibit significant hydroxyl, ABTS, and DPPH radical-scavenging activities. Antioxidant capacity also increases with welan gum concentration. This result provides scientific evidence for the application of welan gum as a novel natural antioxidant and offers a new approach for develo** environmentally friendly and efficient antioxidants. Further research is needed to explore the active components and antioxidant mechanisms of welan gum as well as its potential benefits in practical applications. Additionally, studies on the safety and stability of welan gum are essential foci of future work. These investigations will contribute to a deepened understanding of the potential of welan gum as a natural antioxidant and provide support for its application in various fields, such as food, medicine, and cosmetics.

Discussion

The efficient removal of adhered impurities, such as pigments, proteins, and bacterial cells, from high-viscosity welan gum is crucial for expanding the application of welan gum in the food and cosmetics industries. Traditional crude extraction and purification methods, which involve precipitation with isopropanol or n-butanol followed by drying, result in the irreversible aggregation of large molecular impurities with welan gum, thus posing considerable challenges to subsequent processing.

Some studies have focused on reducing the use of organic solvents to decrease production costs. Wei et al. employed (NH4)2SO4 as the sole nitrogen source and screened the high-yielding welan gum mutant B-8 through UV-ARTP compound mutagenesis (Wei et al. 2022). The ethanol requirement during the purification of ON-welan produced by this mutant reduced by 95%. Chang et al. used bioinformatics analysis to investigate the characteristics and functions of welan gum lyase (WelR) from Sphingomonas sp. WG. They identified key amino acid residues and examined its enzymatic activity under various temperature and pH conditions to explore the production and degradation of welan gum during fermentation, thereby advancing the regulation and industrial production of welan gum (Chang et al. 2021). Li et al. obtained refined welan gum through the fermentation of pretreated sugarcane syrup followed by centrifugation, concentration, precipitation, filtration, washing, dissolution, and vacuum freeze-drying (Li et al. 2020).

Liu et al. pointed out that the poor environmental tolerance of Sphingomonas sp., the high viscosity and weak acidity resulting from welan gum accumulation, and the pigments produced during carotenoid synthesis lead to the high energy consumption and costs of polysaccharide purification (Liu et al. 2020). Ge et al. found that the pigment adsorption capacity of welan gum is pH-dependent, with acidic conditions favoring pigment adsorption (Ge et al. 2022). While studying welan gum/graphene oxide nanocomposite hydrogels, Yu et al. discovered that welan gum has excellent pigment adsorption ability, which indicates its weak ability to remove carotenoids (Yu et al. 2015). Zhao et al. considerably reduced the molecular weight (approximately 68 kDa) of welan gum by knocking out srtW and changing the capsule morphology of Sphingomonas sp. (Zhao et al. 2021). However, the new welan gum with medium molecular weight was similar in size to proteins. Multiple steps, such as dilution, centrifugation, alcohol precipitation, protein removal through the Sevage method, and separation by using a DEAE anion exchange column (1.6 × 40 cm), were employed to achieve purification.

Our present study showed that enzyme purification methods possess unique advantages over traditional methods. First, enzymatic hydrolysis is simple to operate and cost-effective. Second, it avoids the use of large amounts of toxic organic reagents, thus preserving the strong biological activity of welan gum. Third, it has a minimal influence on the structure and molecular weight of welan gum. Lastly, it greatly enhances the transparency of welan gum. Our research achieved a removal rate of 83.5% for welan gum in the fermentation broth of Sphingomonas sp. ATCC 31555 by investigating factors, such as lysozyme hydrolysis time and enzyme concentration. Furthermore, we applied computer-aided enzymatic hydrolysis prediction to evaluate the alkaline protease hydrolysis of proteins in welan gum fermentation broth. Our work thus marks the first application of computer-aided technology in the optimization of welan gum production processes. Our experimental results confirmed the effects of alkaline protease hydrolysis time, enzyme concentration, hydrolysis temperature, pH, and stirring rate on sugar recovery and protein, pigment, and bacterial removal rates. Through comprehensive analysis, we identified the optimal conditions as the enzyme dosage of 7500 U/g, 50 ℃, pH 10, and 600 rpm. These conditions provided the SRR of 76.1%, PRR of 87.3%, BRR of 95.2%, and CRR of 89.5%. The structural evaluation of welan gum treated with the combination of lysozyme and alkaline protease revealed no significant difference. We utilized RSM for optimization and identified the optimal conditions as the enzyme dosage of 11 000 U/g, temperature of 44 °C, and pH of 9. Purification improved the polymerization degree and molecular weight distribution uniformity of the gum, and the enzymatically treated welan gum exhibited high antioxidant activity. Additionally, our proposed mild treatment method expands the potential applications of welan gum in food additives, cosmetics, and other fields, thus providing new possibilities for the utilization of welan gum.

Data availability

The data that support the findings of this study are in this published article and available from the corresponding author upon reasonable request.

References

Andrew M, Jayaraman G (2020) Structural features of microbial exopolysaccharides in relation to their antioxidant activity. Carbohydr Res 487:107881. https://doi.org/10.1016/j.carres.2019.107881

Baudoin NA, Schexnayder PF, Isa IK, Chirdon WM (2023) Interfacial and rheological investigation of enhanced oil recovery agents derived from Spirulina biomass. Fuel 342:127728. https://doi.org/10.1016/j.fuel.2023.127728

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1):248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Carmona JA, Ramirez P, Calero N, Munoz J (2023) Effect of the welan gum concentration on the rheological and structural behaviour of biocomposite hydrogels with sepiolite as filler. Polymers 15(1):33. https://doi.org/10.3390/polym15010033

Chang AP, Qian J, Li H, Wang YL, Lin JY, He QM, Shen YL, Zhu H (2021) Characterization and function of a novel welan gum lyase from marine Sphingomonas sp. WG Front Microbiol 12:638355. https://doi.org/10.3389/fmicb.2021.638355

Consortium U (2015) UniProt: a hub for protein information. Nucleic Acids Res 43(D1):D204–D212. https://doi.org/10.1093/nar/gku989

Cu YC, Majumder K, Wu JP (2011) QSAR-aided approach in evaluation of food proteins as precursors of ACE inhibitory peptides. Food Res Int 44(8):2465–2474. https://doi.org/10.1016/j.foodres.2011.01.051

Ge H, Ding K, Guo F, Wu X, Zhai N, Wang W (2022) Green and superior adsorbents derived from natural plant gums for removal of contaminants: a review. Materials 16(1):179. https://doi.org/10.3390/ma16010179

Hsieh CH, Wang TY, Hung CC, Jao CL, Hsieh YL, Wu SX, Hsu KC (2016) In silico, in vitro and in vivo analyses of dipeptidyl peptidase IV inhibitory activity and the antidiabetic effect of sodium caseinate hydrolysate. Food Funct 7(2):1122–1128. https://doi.org/10.1039/c5fo01324k

Kaur V, Bera MB, Panesar PS, Kumar H, Kennedy JF (2014) Welan gum: microbial production, characterization, and applications. Int J Biol Macromol 65:454–461. https://doi.org/10.1016/j.ijbiomac.2014.01.061

Kawasaki S, Moriguchi R, Sekiya K, Nakai T, Ono E, Kume K, Kawahara K (1994) The cell envelope structure of the lipopolysaccharide-lacking gram-negative bacterium Sphingomonas paucimobilis. J Bacteriol 176(2):284–290. https://doi.org/10.1111/j.1365-2672.1994.tb04357.x

Li Q, Zhou Y, Ke C, Bai Y, Liu X, Li S (2020) Production of welan gum from cane molasses by Sphingomonas sp FM01. Carbohydr Polym 244:116485. https://doi.org/10.1016/j.carbpol.2020.116485

Li B, Li H, Liu J, Zhang Z, Chen M, Yue L, Lu W, Ji S, Wang D, Zhu H (2022) Enzymatic degradation, antioxidant and rheological properties of a sphingan WL gum from Sphingomonas sp. WG Int J Biol Macromol 210:622–629. https://doi.org/10.1016/j.ijbiomac.2022.04.218

Liu X, Zhao M, Xu Z, Xu H, Li S (2020) Construction of a robust Sphingomonas sp strain for welan gum production via the expression of global transcriptional regulator IrrE. Front Bioeng Biotechnol 8:674. https://doi.org/10.3389/fbioe.2020.00674

Lopes L, Milas M, Rinaudo M (1994) Influence of the method of purification on some solution properties of welan gum. Int J Biol Macromol 16(5):253–258. https://doi.org/10.1016/0141-8130(94)90030-2

Lu Z, Lee PR, Yang HS (2023) Synergistic adsorption of surface-active components at the air-liquid interface improves foaming properties of plant-based egg analogues. Food Hydrocoll 137:108414. https://doi.org/10.1016/j.foodhyd.2022.108414

MacLean B, Tomazela DM, Shulman N, Chambers M, Finney GL, Frewen B, Kern R, Tabb DL, Liebler DC, MacCoss MJ (2010) Skyline: an open source document editor for creating and analyzing targeted proteomics experiments. Bioinformatics 26(7):966–968. https://doi.org/10.1093/bioinformatics/btq054

Masuko T, Minami A, Iwasaki N, Majima T, Nishimura S, Lee YC (2005) Carbohydrate analysis by a phenol-sulfuric acid method in microplate format. Anal Biochem 339(1):69–72. https://doi.org/10.1016/j.ab.2004.12.001

Mooney C, Haslam NJ, Holton TA, Pollastri G, Shields DC (2013) PeptideLocator: prediction of bioactive peptides in protein sequences. Bioinformatics 29(9):1120–1126. https://doi.org/10.1093/bioinformatics/btt103

More VS, Ebinesar A, Prakruthi A, Praveen P, Fasim A, Rao A, Zameer F, Anantharaju KS, More S (2021) Isolation and purification of microbial exopolysaccharides and their industrial application. In: Vaishnav A, Choudhary DK (eds) Microbial Polymers: Applications and Ecological Perspectives. Springer Singapore, Singapore, pp 69–86

Nsengiyumva EM, Alexandridis P (2022) Xanthan gum in aqueous solutions: fundamentals and applications. Int J Biol Macromol 216:583–604. https://doi.org/10.1016/j.ijbiomac.2022.06.189

Roca C, Alves VD, Freitas F, Reis MAM (2015) Exopolysaccharides enriched in rare sugars: bacterial sources, production, and applications. Front Microbiol 6:288. https://doi.org/10.3389/fmicb.2015.00288

Simmons D (1962) The glucosidic linkages of the Shigella flexneri polysaccharides. Biochem J 84(2):353. https://doi.org/10.1042/bj0840353

Tu M, Cheng S, Lu W, Du M (2018) Advancement and prospects of bioinformatics analysis for studying bioactive peptides from food-derived protein: sequence, structure, and functions. TrAC, Trends Anal Chem 105:7–17. https://doi.org/10.1016/j.trac.2018.04.005

Udenigwe CC, Aluko RE (2012) Food Protein-Derived Bioactive Peptides: Production, Processing, and Potential Health Benefits. J Food Sci 77(1):R11–R24. https://doi.org/10.1111/j.1750-3841.2011.02455.x

Wei L, Mao Y, Liu H, Ke C, Liu X, Li S (2022) Effect of an inorganic nitrogen source (NH4) 2SO4 on the production of welan gum from Sphingomonas sp. mutant obtained through UV-ARTP compound mutagenesis. Int J Biol Macromol 210:630–638. https://doi.org/10.1016/j.ijbiomac.2022.04.219

Wen CR, Sun ZQ, Elfaruk MS, Putta A, Pang J, Janaswamy S (2021) Effect of charge balancing cations on the viscoelastic and thermal properties of welan. Carbohydr Polym Tech 2:100130. https://doi.org/10.1016/j.carpta.2021.100130

Wu M, Huang H, Li G, Ren Y, Shi Z, Li X, Dai X, Gao G, Ren M, Ma T (2017) The evolutionary life cycle of the polysaccharide biosynthetic gene cluster based on the Sphingomonadaceae. Sci Rep 7(1):1–14. https://doi.org/10.1038/srep46484

Wu T, Jiang Q, Wu D, Hu Y, Chen S, Ding T, Ye X, Liu D, Chen J (2019) What is new in lysozyme research and its application in food industry? A review. Food Chem 274:698–709. https://doi.org/10.1016/j.foodchem.2018.09.017

Xu X, Nie Z, Zheng Z, Zhu L, Zhan X (2017) Production and rheological properties of welan gum produced by Sphingomonas sp. ATCC 31555 with different nitrogen sources. J Mol Microbiol Biotechnol 27(1):55–63. https://doi.org/10.1159/000452835

Yu M, Song A, Xu G, **n X, Shen J, Zhang H, Song Z (2015) 3D welan gum–graphene oxide composite hydrogels with efficient dye adsorption capacity. RSC Adv 5(92):75589–75599. https://doi.org/10.1039/C5RA12806D

Zhang W, Chen Z, Wu M, Shi Z, Zhu F, Li G, Ma T (2016) Improved production of carotenoid-free welan gum in a genetic-engineered Alcaligenes sp. ATCC31555. Biotechnol Lett 38:991–997. https://doi.org/10.1007/s10529-016-2068-5

Zhao M, Zhang H, Xu X, Li S, Xu H (2021) A strategy for the synthesis of low-molecular-weight welan gum by eliminating capsule form of Sphingomonas strains. Int J Biol Macromol 178:11–18. https://doi.org/10.1016/j.ijbiomac.2021.02.157

Zhao M, Hu Y, Yao H, Huang J, Li S, Xu H (2022) Sustainable production and characterization of medium-molecular weight welan gum produced by a Sphingomonas sp. RW Carbohydr Polym 289:119431. https://doi.org/10.1016/j.carbpol.2022.119431

Zhu P, Chen X, Li S, Xu H, Dong S, Xu Z, Zhang Y (2014) Screening and characterization of Sphingomonas sp. mutant for welan gum biosynthesis at an elevated temperature. Bioprocess Biosyst Eng 37:1849–1858. https://doi.org/10.1007/s00449-014-1159-8

Acknowledgements

We would like to express our gratitude to Y15 Biosystems from Shanghai Biosystems Biotechnology Co., Ltd. for their assistance in the determination of purification indicators in this study. We would also like to extend our appreciation to Shanghai SanShu Biotechnology Co., LTD for their support in the structural analysis of our study. Their expertise and guidance were invaluable in our research efforts.

Funding

This work was supported by the National Key research and development Program of China (Grant No. 2021YFC2101100) and the Priority Academic Program Development of Jiangsu Higher Education Institutions, the 111 Project (No. 111–2-06).

Author information

Authors and Affiliations

Contributions

YYW and XBZ contributed conception and design of the study. TTZ, ZTL, and MJG conducted the experiments. YJ and RTL analyzed the data. YYW wrote the manuscript. XBZ and LZ supervised and participated in revising the paper. All authors contributed to manuscript revision, read, and approved the submitted version.

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Zhang, T., Zhu, L. et al. Optimization of welan gum extraction and purification using lysozyme and alkaline protease. Appl Microbiol Biotechnol 108, 70 (2024). https://doi.org/10.1007/s00253-023-12880-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00253-023-12880-y