Abstract

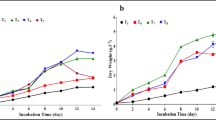

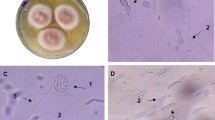

Orange peel waste (OPW), the primary byproduct of the juice extraction process, is annually generated in massive amounts (21 Mton), and its aqueous extraction in biorefining operations yields a liquid fraction, referred to as orange peel extract (OPE). Although OPE contains significant amounts of easily assimilable carbohydrates, such as fructose, glucose, and sucrose, no investigations have been conducted yet to assess its possible use in biodiesel production by oleaginous yeasts. Consequently, the objective of the present study was to assess whether OPE might act as the basis of a liquid medium for microbial lipid production. A screening conducted with 18 strains of oleaginous yeasts in shaken flask on the OPE-based medium showed that Rhodosporidium toruloides NRRL 1091 and Cryptococcus laurentii UCD 68-201 gave the best results in terms of lipid production (5.8 and 4.5 g L−1, respectively) and accumulation (77 and 47% on a dry matter basis, respectively). The subsequent scale transfer of the process to a 3-L STR operated in batch mode halved the time required to reach the lipid peak with the ensuing increase in volumetric productivities in R. toruloides NRRL 1091 (3646 mg L−1 day−1) and C. laurentii UCD 68-201 (2970.7 mg L−1 day−1). The biodiesel yields from the lipids of the former and the latter strain were 36.9 and 31.9%, respectively. Based on multivariate analysis of fatty acid methyl ester compositions, the lipids from the former and the latter strain were highly resembling those of Jatropha and palm oils, two commonly used feedstocks for biodiesel manufacturing.

Similar content being viewed by others

References

Ageitos JM, Vallejo JA, Veiga-Crespo P, Villa TG (2011) Oily yeasts as oleaginous cell factories. Appl Microbiol Biotechnol 90:1219–1227

Ainsworth E, Gillespie K (2007) Estimation of total phenolic content and other oxidation substrates in plant tissues using Folin-Ciocalteu reagent. Nat Protoc 2:875–877

Anderson JM, Ingram JSI (1993) A handbook of methods. Trop. Soil Biol. Fertil. 2nd ed. CAB Int. Wallingford

Ángel Siles López J, Li Q, Thompson IP (2010) Biorefinery of waste orange peel. Crit Rev Biotechnol 30:63–69

Angerbauer C, Siebenhofer M, Mittelbach M, Guebitz GM (2008) Conversion of sewage sludge into lipids by Lipomyces starkeii for biodiesel production. Bioresour Technol 99:3051–3056

Atabani AE, Silitonga AS, Badruddin IA, Mahlia TMI, Masjuki HH, Mekhilef S (2012) A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew Sust Energ Rev 16:2070–2093

Balat M (2011) Potential alternatives to edible oils for biodiesel production - a review of current work. Energy Convers Manag 52:1479–1492

Balu AM, Budarin V, Shuttleworth PS, Pfaltzgraff LA, Waldron K, Luque R, Clark JH (2012) Valorisation of orange peel residues: waste to biochemicals and nanoporous materials. ChemSusChem 5:1694–1697

Beopoulos A, Nicaud JM, Gaillardin C (2011) An overview of lipid metabolism in yeasts and its impact on biotechnological processes. Appl Microbiol Biotechnol 90:1193–1206

Boluda-Aguilar M, García-Vidal L, del Pilar G-CF, López-Gómez A (2010) Mandarin peel wastes pretreatment with steam explosion for bioethanol production. Bioresour Technol 101(10):3506–3513

Carota E, Crognale S, D’Annibale A, Gallo AM, Stazi SR, Petruccioli M (2017) A sustainable use of ricotta cheese whey for microbial biodiesel production. Sci Total Environ 584-585:554–560

Carota E, Crognale S, D’Annibale A, Petruccioli M (2018) Bioconversion of agro-industrial waste into microbial oils by filamentous fungi. Process Saf Environ Protect 117:143–151

Castanha RF, Mariano AP, de Morais LAS, Scramin S, Monteiro RTR (2014) Optimization of lipids production by Cryptococcus laurentii 11 using cheese whey with molasses. Brazil J Microbiol 45:379–387

Cho HU, Park JM (2018) Biodiesel production by various oleaginous microorganisms from organic wastes. Bioresour Technol 256:502–508

Crognale S, Pesciaroli L, Petruccioli M, D’Annibale A (2012) Phenoloxidase-producing halotolerant fungi from olive brine wastewater. Process Biochem 47:1433–1437

Demirbaş A (1998) Fuel properties and calculation of higher heating values of vegetable oils. Fuel 77:1117–1120

Dobrowolski A, Mituła P, Rymowicz W, Mirończuk AM (2016) Efficient conversion of crude glycerol from various industrial wastes into single cell oil by yeast Yarrowia lipolytica. Bioresour Technol 207:237–243

Domini C, Vidal L, Cravotto G, Canals A (2009) A simultaneous, direct microwave/ultrasound-assisted digestion procedure for the determination of total Kjeldahl nitrogen. Ultrason Sonochem 16:564–569

Dourou M, Mizerakis P, Papanikolaou S, Aggelis G (2017) Storage lipid and polysaccharide metabolism in Yarrowia lipolytica and Umbelopsis isabellina. Appl Microbiol Biotechnol 101:7213–7226

Dourou M, Aggeli D, Papanikolaou S, Aggelis G (2018) Critical steps in carbon metabolism affecting lipid accumulation and their regulation in oleaginous microorganisms. Appl Microbiol Biotechnol 102:2509–2523

Dubois M, Gilles KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

El-Nawawi SA, Shehata FR (1987) Extraction of pectin from Egyptian orange peel. Factors affecting the extraction. Biol Wastes 20:281–290

Espina L, Somolinos M, Lorán S, Conchello P, García D, Pagán R (2011) Chemical composition of commercial citrus fruit essential oils and evaluation of their antimicrobial activity acting alone or in combined processes. Food Contr 22:896–902

Fassinou WF, Sako A, Fofana A, Koua KB, Toure S (2010) Fatty acids composition as a means to estimate the high heating value (HHV) of vegetable oils and biodiesel fuels. Energy 35:4949–4954

Fei Q, O’Brien M, Nelson R, Chen X, Lowell A, Dowe N (2016) Enhanced lipid production by Rhodosporidium toruloides using different fed-batch feeding strategies with lignocellulosic hydrolysate as the sole carbon source. Biotechnol Biofuels 9:130

Gopinath A, Puhan S, Nagarajan G (2009) Theoretical modeling of iodine value andsaponification value of biodiesel fuels from their fatty acid composition. Renew Energy 34:1806–1811

Izard J, Limberger RJ (2003) Rapid screening method for quantitation of bacterial cell lipids from whole cells. J Microbiol Meth 55:411–418

Kalayasiri P, Jeyashoke N, Krisnangkura K (1996) Survey of seed oils for use as diesel fuels. J Am Oil Chem Soc 73:471–474

Karamerou EE, Webb C (2019) Cultivation modes for microbial oil production using oleaginous yeasts–a review. Biochem Eng J 151:107322

Kiran EU, Trzcinski A, Webb C (2013) Microbial oil produced from biodiesel by-products could enhance overall production. Bioresour Technol 129:650–654

Kitcha S, Cheirsilp B (2011) Screening of oleaginous yeasts and optimization for lipid production using crude glycerol as a carbon source. Energy Procedia 9:274–282

Knothe G (2005) Dependence of biodiesel fuel properties on the structure of fatty acid alkyl esters. Fuel Process Technol 86:1059–1070

Krisnangkura K (1986) A simple method for estimation of cetane index of vegetable oil methyl esters. J Am Oil Chem Soc 63:552–553

Leiva-Candia DE, Pinzi S, Redel-Macías MD, Koutinas A, Webb C, Dorado MP (2014) The potential for agro-industrial waste utilization using oleaginous yeast for the production of biodiesel. Fuel 123:33–42

Li YH, Liu B, Zhao ZB, Bai FW (2006) Optimized culture medium and fermentation conditions for lipid production by Rhodosporidium toruloides. Chin J Biotechnol 22:650–656

Liu Y, Wang Y, Liu H, Zhang JA (2015) Enhanced lipid production with undetoxified corncob hydrolysate by Rhodotorula glutinis using a high cell density culture strategy. Bioresour Technol 180:32–39

Lohrasbi M, Pourbafrani M, Niklasson C, Taherzadeh MJ (2010) Process design and economic analysis of a citrus waste biorefinery with biofuels and limonene as products. Bioresour Technol 101:7382–7388

Louhasakul Y, Cheirsilp B (2013) Industrial waste utilization for low-cost production of raw material oil through microbial fermentation. Appl Biochem Biotechnol 169:110–122

Luque L, Orr VCA, Chen S, Westerhof R, Oudenhoven S, Rossum GV, Kersten S, Berruti F, Rehmann L (2016) Lipid accumulation from pinewood pyrolysates by Rhodosporidium diobovatum and Chlorella vulgaris for biodiesel production. Bioresour Technol 214:660–669

MacGregor JF, Kourti T (1995) Statistical process control of multivariate processes. Control Eng Pract 3:403–414

Matsakas L, Bonturi N, Miranda EA, Rova U, Christakopoulos P (2015) High concentrations of dried sorghum stalks as a biomass feedstock for single cell oil production by Rhodosporidium toruloides. Biotechnol Biofuels 8:6

Oberoi HS, Vadlani PV, Madl RL, Saida L, Abeykoon JP (2010) Ethanol production from orange peels: two-stage hydrolysis and fermentation studies using optimized parameters through experimental design. J Agric Food Chem 58:3422–3429

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part I: Biochemistry of single cell oil production. Eur J Lipid Sci Technol 113:1031–1051

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biotechnol 58:308–312

Papanikolaou S, Kampisopoulou E, Blanchard F, Rondags E, Gardeli C, Koutinas AA, Chevalot I, Aggelis G (2017) Production of secondary metabolites through glycerol fermentation under carbon-excess conditions by the yeasts Yarrowia lipolytica and Rhodosporidium toruloides. Eur J Lipid Sci Technol 119:1600507

Park WK, Moon M, Kwak MS, Jeon S, Choi GG, Yang JW, Lee B (2014) Use of orange peel extract for mixotrophic cultivation of Chlorella vulgaris: increased production of biomass and FAMEs. Bioresour Technol 171:343–349

Picataggio SK, Smittle RB (1979) Microbiological production of oil. Eur Pat Appl. EP 5277 A2 19791114

Pinzi S, Garcia IL, Lopez-Gimenez FJ, Luque de Castro MD, Dorado G, Dorado MP (2009) The ideal vegetable oil-based biodiesel composition: a review of social, economical and technical implications. Energy Fuel 23:2325–2341

Rangarajan V, Rajasekharan M, Ravichandran R, Sriganesh K, Vaitheeswaran V (2010) Pectinase production from orange peel extract and dried orange peel solid as substrates using Aspergillus niger. Int J Biotechnol Biochem 6:445–453

Sandhu KS, Minhas K (2006) Oranges and citrus juices. In: Hui YH (ed) Handbook of fruits and fruit processing. Blackwell, Oxford, pp 309–358

Santi G, Jasiulewicz J, Crognale S, D’Annibale A, Petruccioli M, Moresi M (2015) High solid loading in dilute acid hydrolysis of orange peel waste improves ethanol production. Bioenergy Res 8:1292–1302

Santomauro F, Fan J, Budarin VL, Parsons S, Clark J, Miller T, Chuck CJ (2018) Microbial oil produced from the fermentation of microwave-depolymerised rapeseed meal. Bioresour Technol Rep 4:159–165

Schutter ME, Dick RP (2000) Comparison of fatty acid methyl ester (FAME) methods for characterizing microbial commun. Soil Sci Soc Am J 64:1659–1668

Sitepu IR, Sestric R, Ignatia L, Levin D, German JB, Gillies LA, Boundy-Mills KL (2013) Manipulation of culture conditions alters lipid content and fatty acid profiles of a wide variety of known and new oleaginous yeast species. Bioresour Technol 144:360–369

Sitepu I, Selby T, Lin T, Zhu S, Boundy-Mills K (2014) Carbon source utilization and inhibitor tolerance of 45 oleaginous yeast species. J Ind Microbiol Biotechnol 41:1061–1070

Soccol CR, Dalmas Neto CJJ, Soccol VT, Sydney EB, da Costa ESF, Medeiros ABP, Vandenberghe de Souza LP (2017) Pilot scale biodiesel production from microbial oil of Rhodosporidium toruloides DEBB 5533 using sugarcane juice: performance in diesel engine and preliminary economic study. Bioresour Technol 223:259–268

Taylor KA, Buchanan-Smith JG (1992) A colorimetric method for the quantitation of uronic acids and a specific assay for galacturonic acid. Anal Biochem 201:190–196

Tchakouteu SS, Chatzifragkou A, Kalantzi O, Koutinas AA, Aggelis G, Papanikolaou S (2015) Oleaginous yeast Cryptococcus curvatus exhibits interplay between biosynthesis of intracellular sugars and lipids. Eur J Lipid Sci Technol 117:657–672

Torrado AM, Cortés S, Salgado JM, Max B, Rodríguez N, Bibbins BP, Converti A, Domínguez JM (2011) Citric acid production from orange peel wastes by solid-state fermentation. Brazil J Microbiol 42:394–409

Tsakona S, Papadaki A, Kopsahelis N, Kachrimanidou V, Papanikolaou S, Koutinas A (2019) Development of a circular oriented bioprocess for microbial oil production using diversified mixed confectionery side-streams. Foods 8:300

Widmer W, Zhou W, Grohmann K (2010) Pretreatment effects on orange processing waste for making ethanol by simultaneous saccharification and fermentation. Bioresour Technol 101:5242–5249

Wiebe MG, Koivuranta K, Penttilä M, Ruohonen L (2012) Lipid production in batch and fed-batch cultures of Rhodosporidium toruloides from 5 and 6 carbon carbohydrates. BMC Biotechnol 12:26

Xavier MCA, Coradini ALV, Deckmann AC, Franco TT (2017) Lipid production from hemicellulose hydrolysate and acetic acid by Lipomyces starkeyi and the ability of yeast to metabolize inhibitors. Biochem Eng J 118:11–19

Xu X, Kim JY, Oh YR, Park JM (2014) Production of biodiesel from carbon sources of macroalgae, Laminaria japonica. Bioresour Technol 169:455–461

Yen HW, Yang YC, Yu YH (2012) Using crude glycerol and thin stillage for the production of microbial lipids through the cultivation of Rhodotorula glutinis. J Biosci Bioeng 114:453–456

Ykema A, Verbree EC, Kater MM, Smit H (1988) Optimization of lipid production in the oleaginous yeast Apiotrichum curvatum in whey permeate. Appl Microbiol Biotechnol 29:211–218

Yong-Hong LI, Bo LIU, Zong-Bao ZHAO, Feng-Wu BAI (2006) Optimization of culture conditions for lipid production by Rhodosporidium toruloides. Chin J Biotechnol 22:650–656

Yousuf A, Sannino F, Addorisio V, Pirozzi D (2010) Microbial conversion of olive oil mill wastewaters into lipids suitable for biodiesel production. J Agric Food Chem 58:8630–8635

Zhao X, Wu S, Hu C, Wang Q, Hua Y, Zhao ZK (2010) Lipid production from Jerusalem artichoke by Rhodosporidium toruloides Y4. J Ind Microbiol Biotechnol 37:581–585

Zhao X, Hu C, Wu S, Shen H, Zhao ZK (2011) Lipid production by Rhodosporidium toruloides Y4 using different substrate feeding strategies. J Ind Microbiol Biotechnol 38:627–632

Funding

This study was funded by the Ministero dell’Istruzione, dell’Università e della Ricerca (MIUR) within the project “Piano Operativo Nazionale Biofeedstock” (grant no. ARS01_00985).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(PDF 315 kb)

Rights and permissions

About this article

Cite this article

Carota, E., Petruccioli, M., D’Annibale, A. et al. Orange peel waste–based liquid medium for biodiesel production by oleaginous yeasts. Appl Microbiol Biotechnol 104, 4617–4628 (2020). https://doi.org/10.1007/s00253-020-10579-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-020-10579-y