Abstract

Tacrolimus (FK506) is an important macrocyclic polyketide showing antifungal and immunosuppressive activities, as well as neuroregenerative properties. Tacrolimus biosynthetic machinery should incorporate the shikimate-derived 4,5-dihydroxycyclohex-1-enecarboxylic acid (DHCHC) as a biosynthetic starter unit into the biosynthetic line of tacrolimus. fkbO is a homologue of rapK encoding chorismatase related to the biosynthesis of starter unit DHCHC from chorismate in the rapamycin biosynthetic gene cluster. FkbO and RapK are good targets for mutational biosynthesis to produce novel analogues of tacrolimus, ascomycin, and rapamycin, which could be important drugs for clinical application in the treatment of cancer and immune and neurodegenerative diseases. To make novel tacrolimus analogues, we prepared an fkbO in-frame deletion mutant, Streptomyces sp. GT110507, from a tacrolimus high producer. We scrutinized the cyclic carboxylic acids that were possibly incorporated instead of DHCHC by precursor-directed mutasynthesis using Streptomyces sp. GT110507 to lead tacrolimus analogues. Among them, trans-4-hydroxycyclohexanecarboxylic acid and 3-hydroxybenzoic acid were successfully incorporated into the tacrolimus backbone, which led to the production of 31-desmethoxytacrolimus and TC-225, respectively. Especially, adding of trans-4-hydroxycyclohexanecarboxylic acid produced a high amount (55 mg/L) of 31-desmethoxytacrolimus. Interestingly, in the rapK mutant, it has been reported that the incorporation of cyclohexanecarboxylic acid (CHC) led to 39-desmethoxy rapamycin. However, in Streptomyces sp. GT110507, CHC is not successfully incorporated. This discrepancy should reflect the differences in the DHCHC biosynthesis mechanism and/or substrate specificity of starter unit loading machineries (FkbP and RapP) of tacrolimus and rapamycin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Tacrolimus (also known as FK506) is a 23-membered macrocyclic polyketide produced by Streptomyces spp. (Kino et al. 1987). It is a compound structurally similar to rapamycin and ascomycin (FK520), containing a tricyclo skeleton (Fig. 1), and is a clinically important immunosuppressant drug to prevent the rejection of transplanted organs and in the treatment of autoimmune diseases, such as atopic dermatitis (Parsons et al. 1993). The immunosuppressive mechanism of tacrolimus is related to the binding of an immunophilin, FKBP12 (Aldape et al. 1992). The tacrolimus/FKBP12 complex inhibits the activity of calcineurin, which has phosphatase activity that is necessary for the dephosphorylation of nuclear factor to release interleukin-2 and other downstream cytokines for immune response in activated T cells.

Tricyclo backbone of tacrolimus, ascomycin, and rapamycin is required for the FKBP binding domain (Driggers et al. 2008). Other parts of their polyketide backbone are required for attachment to calcineurin or mammalian target of rapamycin (mTOR) (Huang and Houghton 2003). Many analogues with a modified tricyclo skeleton and polyketide backbone of tacrolimus, ascomycin, and rapamycin have been synthesized. Some, such as pimecrolimus (Elidel™, SDZ-ASM 981, 33-epi-chloro-33-desoxyascomycin; Hultsch et al. 1998), everolimus (RAD-001, 40-O-(2-hydroxyethyl) derivative of sirolimus; Sedrani et al. 1998), temsirolimus (CCI-779; Wan et al. 2006), JNJ460 (Armistead et al. 1995), and FK1706 (Price et al. 2005), are promising as immunosuppressants, anticancer agents, and neuroregenerators. Most have been recently synthesized and expand the molecular structural diversity of the tricyclo polyketides by virtue of the adaptive biosynthetic, genetic, or biological methods used (Kennedy 2008).

Recently, tacrolimus biosynthetic gene clusters were fully uncovered from Streptomyces sp. ATCC55098 (MA6858), Streptomyces kanamyceticus KCTC 9225, Streptomyces sp. KCTC 11604BP, and Streptomyces tsukubaensis by our group and Petković’s group (Fig. 2) (Mo et al. 2011; Goranovic et al. 2010). The elucidated tacrolimus biosynthetic machineries consist of three main polyketide synthetases (FkbA, FkbB, and FkbC) and nonribosomal peptides synthase or pipecolate-incorporating protein (FkbP), 21-allylmalonyl moiety synthesis-related enzymes (TcsA, TcsB, TcsC, and TcsD), methoxymalonyl-ACP biosynthesis-related enzymes (FkbG, FkbH, FkbI, FkbJ, and FkbK), 31-O-methyltransferase (FkbM), C9 hydroxylase (FkbD), starter unit (shikimate-derived 4,5-dihydroxycyclohex-1-enecarboxylic acid, DHCHC) biosynthesis-related enzyme (FkbO), and type II thioesterase (FkbQ).

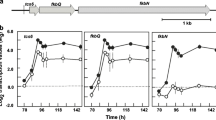

Organization of the tacrolimus biosynthetic gene cluster from Streptomyces sp. KCTC 11604BP (a). Construction of the fkbA deletion mutant (Streptomyces sp. GT110506) (b) and the fkbO deletion mutant (Streptomyces sp. GT110507) (c) by PCR-targeted gene disruption using aac(3)IV-oriT cassette and Southern blot analysis of genomic DNA from Streptomyces sp. GT1105 [lane 1 in d, e], Streptomyces sp. GT110506 [lane 2 in d], and Streptomyces sp. GT110507 [lane 1 in e]. The genomic DNAs were digested with BamHI and hybridized with specific probes of fkbA and fkbO fragments amplified by PCR. For a detailed analysis, see the “Materials and methods” section

Mutasynthesis, precursor-directed biosynthesis, biotransformation, and genetic manipulation have been used to make analogues. To date, many of the analogues, such as prolyl analogues of rapamycin (Khaw et al. 1998), allylmalonyl derivates of tacrolimus (Mo et al. 2011), starter unit (cyclohexyl derivatives) analogues of rapamycin (Lowden et al. 2004; Gregory et al. 2005; Andexer et al. 2011), tacrolimus (US patent no. 5,324,644), ascomycin (Shafiee et al. 1993), pipecolate ring analogues of rapamycin (Ritacco et al. 2005), and polyketide chain analogues of ascomycin (Reeves et al. 2002; Regentin et al. 2002) have been reported.

For the mutasynthesis, fkbO, fkbL, fkbD, and fkbM and tcsA, tcsB, tcsC, and tcsD could be good target genes. Recently, enzymatic function of RapK in rapamycin biosynthesis is uncovered. RapK identified as a chorismatase that is a new family enzyme-related DHCHC synthesis from chorismate in the shikimate pathway (Andexer et al. 2011). FkbO is a homologue of RapK in tacrolimus and ascomycin biosynthesis.

Here, we report the preparation of an analogue of 31-desmethoxytacrolimus through mutasynthesis using an fkbO deletion mutant of a tacrolimus high producer and increased tacrolimus production through the overexpression of fkbO.

Materials and methods

Bacterial strains, vectors, primers, and cultivation

All bacterial strains, plasmids, fosmids, and primers used in this study are listed in Table 1. Streptomyces sp. KCTC 11604BP and S. kanamyceticus KCTC 9225 were used as producers of tacrolimus (Mo et al. 2011). The spore suspensions and genomic DNA of Streptomyces strains were prepared according to general methods (Kieser et al. 2000). The spore suspensions were kept in a deep freezer (−70 °C) until used for experiments.

For fermentation studies of Streptomyces strains, a seed culture was carried out in a 500-ml Erlenmeyer flask containing 30 ml of seed medium (1 % oxidized starch, 1 % glycerol, 2 % soybean meal, 0.2 % CaCO3, and 0.5 % corn steep liquor) for 36 h at 28 °C in a rotary shacking incubator with 240 rpm. The seed culture was inoculated into a main culture (10 % inoculum size) for flask and jar fermentation studies. For flask fermentation studies, the seed culture was inoculated in a 500-ml baffled flask containing 30 ml of main medium (7 % oxidized starch, 1.7 % yeast powder, 0.5 % soybean meal, 0.1 % (NH4)2SO4, and 0.1 % CaCO3) and cultivated on an orbital shaker operating at 240 rpm for 6 days at 28 °C. For jar fermentation studies, the seed culture was inoculated in a 5-L jar fermentor containing 3 L of main medium and cultivated for 6 days at 28 °C under at 800 rpm and an air flow rate of 1.0 vvm to maintain dissolved oxygen content exceeding 40 %. Occasionally, a hydrophobic resin, like Diaion HP-20, Amberlite XAD-4, Amberlite XAD-7H, and Amberlite XAD-16, was added into the main medium before sterilization and carboxylic acids were added during cultivation. To obtain good fermentation results, at least triplicate experimental sets were tested.

Escherichia coli DH5α was used as a host for the general cloning experiments. E. coli ET12567/pUZ8002 was used as a donor strain for intergeneric conjugation between E. coli and Streptomyces. E. coli BW25113/pIJ790 was used for polymerase chain reaction (PCR)-targeting gene disruption experiment. E. coli DH5α, ET12567/pUZ8002, and EPI300 were cultured in Luria–Bertani medium at 37 °C supplemented with appropriate antibiotics. E. coli BW25113/pIJ790 was grown at 30 °C in Luria–Bertani medium containing 25 μg/ml chloramphenicol.

Other preparations of media and cultivation of Streptomyces and E. coli for genetic engineering and DNA manipulation were performed according to general methods (Kieser et al. 2000; Sambrook and Russell 2001).

Fosmids library construction and sequencing

The fosmid libraries were constructed using the Copy Control Fosmid Construction Kit according to the manufacturer’s protocols (Epicentre Biotechnology, Madison, WI, USA) with the following modifications. The genomic DNA of Streptomyces sp. KCTC 11604BP and S. kanamyceticus KCTC 9225 were prepared with standard procedures (Kieser et al. 2000). The genomic DNA was physically fragmented DNA by an ultrasonicator. The fragments approximately 40 kb were purified by extraction from agarose gel after pulsed field gel electrophoresis. The DNA fragments were end-repaired to generate blunt ends and ligated into the Eco72 I site of the pCCFOS1 fosmid vector and packed with a MaxPlax Packaging Extract (Epicentre Biotechnology, Madison, WI, USA) system.

The DNA sequencing was performed by the Sanger method using an ABI3700xl sequencer (Applied Biosystems, Foster City, CA, USA). A consecutive sequence from fosmid clones was automatically processed and assembled from shotgun sequencing data with the PHRED/PHRAP/Consed software (http://www.phrap.org). Annotation analysis of the sequence data was performed through database comparison with the Basic Local Alignment Search Tool server of the National Center for Biotechnology Information (http://blast.ncbi.nlm.nih.gov./Blast.cgi). All sequences are available in GenBank as accession numbers HM116537 and HM116536.

Selection of a high-yield producer, Streptomyces sp. GT1105, by random mutagenesis

The random mutagenesis of wild-type strain, Streptomyces sp. KCTC 11604BP, was done by traditional mutagenesis with ultraviolet (UV) irradiation to obtain a high-yield tacrolimus-producing strain. UV-mediated random mutagenesis was carried out by transferring 10 ml (~108 spores/ml) of the spore suspension to an uncovered Petri dish (90 × 15 mm) and exposing it for 60 s under a UV lamp positioned at a height of 4.5 cm. After UV irradiation, the spore suspension was diluted appropriately and 1 ml of the diluted spore suspension on was spread onto ISP2 agar and incubated at 30 °C for 7 days. A total of 1,160 separate colonies were tested for the tacrolimus production. Among of them, the highest tacrolimus producer (~120 mg/L), Streptomyces sp. GT1105, was selected.

Gene inactivation of fkbO and fkbA and their confirmation

The fkbA and fkbO in Streptomyces sp. GT1105 were disrupted by gene replacement with the λ-RED PCR-targeting method (Gust et al. 2003) to generate fkbA-deficient mutant and fkbO-deficient mutant strains, respectively. For disruption of fkbA and fkbO in Streptomyces sp. GT1105, the SpeI and XbaI DNA fragment of Fos-1006D05 about 41 kb in size was cloned into the cosmid vector SuperCosI digested with XbaI to generate the Cos-1006D05 cosmid. Cos-1006D05 was transformed into E. coli BW25113/pIJ790 for introduced disruption of fkbA and fkbO. An apramycin resistance gene/oriT cassettes (aac(3)IV-oriT) for replacement fkbO and fkbA were amplified using primer sets (Del-fkbA-F/R for deletion of fkbA and Del-fkbO-F/R for deletion of fkbO), respectively. The amplified cassettes were introduced into E. coli BW25113/pIJ790 with Cos-1006D05. The mutated cosmids were confirmed by PCR and restriction enzyme analysis. Cosmids pΔfkbO(ΔfkbO) or pΔfkbA(ΔfkbA) were introduced into E. coli ET12567/pUZ8002 by electroporation and then transferred to Streptomyces sp. GT1105 by conjugation. After incubation at 30 °C for 18 h, each plate was overlaid with 1 ml of sterile water containing 200 μg of nalidixic acid and 500 μg of apramycin. The double-crossover mutants were first selected based on apramycin resistance and kanamycin sensitivity. The resulting deletion mutants of fkbA and fkbO were designated Streptomyces sp. GT110506 and Streptomyces sp. GT110507, respectively, and they were confirmed by PCR using check-fkbO-F/R and check-fkbA-F/R primer sets and Southern blot analysis using the DIG DNA Labeling and Detection Kit according to the supplier’s manual (Roche Applied Science). For the Southern blot analysis, genomic DNAs from Streptomyces sp. GT110506 and Streptomyces sp. GT110507 were digested with BamHI and separated on a 0.8 % agarose gel by electrophoresis. Hybridizations were conducted at high stringency with probe DNA fragments amplified with fkbA-probe-F/R and fkbO-probe-F/R sets for fkbA and fkbO deletion checking, respectively. The mutated sites were finally confirmed by showing the band signal of 1.4 and 0.6 kb instead of 3.4 and 1.8 kb for fkbA and fkbO deletion, respectively (Fig. 2).

Construction of pGE-SIO and pGE-SKO for expression of the fkbO genes

The fkbO gene (SI-fkbO) from Fos-1006D05 was amplified using primers SI-fkbO-F/R with BamHI and XbaI restriction sites. The fkbO gene (SK-fkbO) from Fos1012A09 was amplified using primers SK-fkbO-F/R with XbaI restriction sites. SI-fkbO (1,136 bp) and SK-fkbO (999 bp) PCR products were cloned into a pGEM-T easy vector (Promega, Madison, WI, USA) to give pGEM-SIO and pGEM-SKO, respectively. These genes were verified by sequencing using T7 primer and SP6 primer in pGEM-T easy vector. An integrative E. coli–Streptomyces shuttle vector, pGE-1, for gene expression in Streptomyces strains was used. It is a derivative vector of pSET152 containing the constitutive promoter, P ermE*. A BamHI/XbaI DNA fragment from pGEM-SIO was ligated into pGE-1 digested with the same restriction enzyme to give pGE-SIO. An XbaI DNA fragment from pGEM-SKO was ligated into pGE-1 digested with the same restriction enzyme to give pGE-SKO. pGE-SIO or pGE-SKO plasmids were transferred into Streptomyces sp. GT1105 and Streptomyces sp. GT110507 by intergeneric conjugation using E. coli ET12567 (pUZ8002) and kanamycin resistance selection.

Analysis of tacrolimus and its derivatives

The cultivated broths of the Streptomyces strains were mixed with an equal volume acetone, and it was shaken for 60 min at room temperature. Then, the supernatant containing metabolites was obtained by centrifugation at 9,800×g for 5 min. The supernatants were analyzed for antifungal activity and production of tacrolimus and its derivatives by bioassay and high-performance liquid chromatography (HPLC). In the case of adsorption resin added fermentation, the resin was harvested without broth from cultivate and the metabolites were extracted with acetone and then analyzed. Antifungal activity was measured by a paper disk agar diffusion method with Aspergillus niger ATCC6275 as a sensitive host. HPLC was carried out using a Zorbax XDB C8 analytical column (150 × 4.6 mm, 5 μm). The mobile phases consisted of buffer A (0.01 % trifluoroacetic acid in water) and buffer B (100 % acetonitrile). Gradient elution was performed ranging from 40 to 54 % buffer B solution. The column temperature was maintained at 60 °C. The flow rate was 2 ml/min and monitoring was done at 210 nm.

Purification of 31-desmethoxytacrolimus and TC-225

About 100 mg of active substance (31-desmethoxytacrolimus) was extracted with 2 L acetone from 150 ml of HP-20 resin harvested from Streptomyces sp. GT110507 cultured broth supplemented with 4-hydroxycyclohexanecarboxylic acid (4-HHA). The extract was evaporated until residue was left and 800 ml of distilled water was added to it. Then, the active substance was extracted with an equal volume of ethyl acetate. The extract was evaporated to dryness and then reconstituted with hexane. It was loaded onto a silica column (4 × 10 cm) equilibrated with 100 % hexane and eluted with hexane/ethyl acetate 100:0–90:10, v/v (in percent). The active substances containing fractions were collected and concentrated until the solvent was completely eliminated by rotary evaporation at 40 °C. The concentrate was dissolved in 10 ml of 45 % acetone and loaded onto a column (1.5 × 6 cm) packed with Amberchrom CG161m resin that is equilibrated with 40 % acetone. Chromatography of CG161m was performed by washing and eluting with 100 ml of 52 % acetone to obtain the active substance. The eluted active fractions were collected and concentrated by evaporating until only water remained, and 31-desmethoxytacrolimus was re-extracted with ethyl acetate. The extract was evaporated to dryness and then reconstituted with acetone. Distilled water was dropped slowly to the solution with stirring until it produced a white powder of 31-desmethoxytacrolimus. Finally, about 50 mg of purified 31-desmethoxytacrolimus was obtained.

TC225 was obtained from 6-day cultivated broth added to 1 mM of 3-hydroxybenzoic acid (3-HBA) in 2-day Streptomyces sp. GT110507 cultivates. TC225 was simply prepared by eluting Sep-Pak C18 cartridges (Waters Associates, Milford, MA, USA) with stepwise increment of acetone solution (50–100 %).

Instrumental analysis

Liquid chromatography/mass spectrometry (LC/MS) was performed using the HP1100 series plus MSD (G1958) system (ESI mode; Agilent Technologies, Palo Alto, CA, USA) with a Zorbox XDB C8 column (4.6 × 150 mm, 5 μm). Elution was with 55 % acetonitrile over 30 min at a flow rate of 0.8 ml/min. MS data was acquired through scanning from 100 to 1,000 m/z in the positive mode.

Nuclear magnetic resonance (NMR) data of 31-desmethoxytacrolimus were acquired on Bruker Avance II 500 spectrometer operated at 500.13 MHz for protons and 125.77 MHz for carbons in CDCl3.

Chemicals

Shikimate, cyclohexanecarboxylic acid (CHC), 3-HBA, 4-hydroxybenzoic acid, trans(cis)4-HHA, isonipecotic acid, 4-methylcyclohexanecarboxylic acid, trans-4-(aminomethyl)cyclohexanecarboxylic acid, and 4-(hydroxymethyl)cyclohexanecarboxylic acid were purchased from Tokyo Chemical Industry (Tokyo, Japan).

Results

Yield-up of tacrolimus by mutation and the addition of adsorption resin

Occasionally, the marginal production of metabolites from a wild-type strain could be an obstacle to the analysis of metabolites in the field of their biosynthetic machineries study and the creation of new metabolites through genetic engineering, etc. In this study, for more convenient analysis of metabolites (analogues of tacrolimus), we achieved the high production of tacrolimus by random mutagenesis of wild-type strain and addition of adsorption resin in broth. Streptomyces sp. GT1105 was constructed as a high producer of tacrolimus (120 mg/L) from the wild-type strain Streptomyces sp. KCTC 11604BP (10 mg/L) by general random mutagenesis with UV irradiation. We did not find any differences on metabolite patterns and sequences of genes in tcs clusters (including fkbO, fkbN, etc.) of Streptomyces sp. GT1105 and Streptomyces sp. KCTC 11604BP.

Tacrolimus production yield was increased about twofold to threefold by adding an adsorption resin like Diaion HP-20, Amberlite XAD-4, Amberlite XAD-7H, and Amberlite XAD-16 to the cultivation medium. The most effective resin was 5 % Diaion HP-20 (data not shown). The increasing effect may be caused by diminishing the adsorption of tacrolimus and its derivatives on cell hydrophobic substances (cell membrane or wall components) of Streptomyces for adsorption resin. The addition of adsorption resin was very useful for the elucidation of metabolites.

Settings for PCR-targeting system and identification of tcs cluster

Using fosmid clones, we did not get any recombinant by PCR targeting, even with repeated trials. That may come from insufficient recombination for low copy number of fosmids. Therefore, the approximately 41 kb tacrolimus biosynthetic gene cluster in the fosmid, Fos-1006D05, was moved to SuperCos1 (medium copy number cosmid) and generated Cos-1006D05 to give a high chance of recombination. An fkbA deletion mutant (Streptomyces sp. GT110506) was easily made by PCR targeting using Cos-1006D05. The metabolites of Streptomyces sp. GT110506 were scrutinized to compare with that of the parent strain (GT1105) by HPLC and LC/MS analysis to determined tacrolimus and its related compounds. Streptomyces sp. GT110506 does not produce any tacrolimus and its analogues, such as ascomycin, 36,37-dihydrotacrolimus, prolyl tacrolimus, decarbonyl tacrolimus, tacrolimus tautomer I and II, and 31-O-demethyl tacrolimus (Fig. 3b). Also, the cultivated broth of GT110506 did not display antifungal activity (Fig. 5b). The result implied that the obtained tacrolimus biosynthesis machinery was correct, that all of the aforementioned tricylclo polyketides were made by the same polyketide synthase (PKS) machinery, and that the antifungal activities were in accord with the production of tacrolimus and its analogues. Therefore, the machinery given provided tools for the simultaneous creation of several new compounds through just one genetic engineering based on the one strain produces many compounds approach.

Overexpression of FkbO for yield-up of tacrolimus

Overexpression vectors for known or predicted regulators in tcs, FkbN, Tcs2, and FkbO (it has also been predicted as a kind of regulator; Gregory et al. 2005) were made in Streptomyces sp. GT1105. The vectors constructed enabled the constitutive expression by a Streptomyces strong promoter, P ermE*. FkbN-overexpressed and Tcs2-overexpressed strains did not show any apparently increasing or decreasing production (data not shown). Interestingly, the overexpression of FkbO apparently increased tacrolimus production of 58 % (FkbO-SI, n = 6, three independent experiments) and 64 % (FkbO-SK, n = 6, three independent experiments) (Fig. 4). FkbO was recently shown to be a chorismatase and not to have a regulator function. Therefore, according to our results, we proposed that adding shikimate (as a precursor of DHCHC) increased production of tacrolimus, but the addition of shikimate into the fermentation broth during cultivation of GT1105 did not affect production (data not shown).

Comparison of tacrolimus production in Streptomyces sp. GT1105 and fkbO overexpressed strains. pGE-SIO and pGE-SKO were constructed using two fkbO genes (SI-fkbO and SK-fkbO) from Streptomyces sp. KCTC 11604BP and S. kanamyceticus KCTC 9225, respectively. Both of the fkbO genes were controlled by a promoter, P ermE*, in the integrative vector pGE-1

Inactivation of fkbO and its complementation

Strain GT110507 was constructed as an fkbO deletion mutant from Streptomyces sp. GT11005 by PCR targeting (Fig. 2a) using Cos-1006D05. The fkbO deletion mutation was verified by Southern blot analysis (Fig. 2d) and the lack of a polar effect in strain GT110507 was confirmed by the restoration of tacrolimus production of the complemented strain with pGE-SIO. The introducing of pGE-SIO under controlled by P ermE* recovered approximately 70 % of the yield of tacrolimus and its analogues (Fig. 3d). The restoration of tacrolimus production implied that fkbO downstream genes including fkbP and fkbA could be expressed by the promoter P apr in a deletion cassette used for the construction of the fkbO mutant. We did not find any big differences in the metabolite HPLC patterns of the fkbO mutant (GT110507) with that of the fkbA mutant (GT110506) (Fig. 3a, d). However, unlike strain GT110506, strain GT110507 still possessed the ability to produce some of the metabolites showing very weak antifungal activity (Fig. 5c). A trace amount of tacrolimus was detected from GT110507 by LC/MS. The trace amount may have been biosynthesized by the intact tacrolimus biosynthetic machinery (except FkbO) using DHCHC or its analogue that originated from the complex fermentation medium used.

Antifungal activity of culture broth from Streptomyces strains. The culture broth were obtained from Streptomyces sp. GT1105 (a), Streptomyces sp. GT110506 (b), Streptomyces sp. GT110507 (c), and Streptomyces sp. GT110507 supplemented with 4-hydroxy-cyclohexanecarboxylic acid (d), 3-HBA (e), and 4-aminomethyl-cyclohexanecarboxylic acid (f). The samples were obtained by extraction with acetone from fermented broth for 6 days, and before assay, the paper disk was dried on air. The control used acetone as extraction solvent (g)

Production of tacrolimus derivatives by feeding of starter unit analogues

DHCHC is a starter unit of tacrolimus biosynthesis (Wilson et al. 1998). The incorporation of starter unit analogues instead of DHCHC using strain GT110507 to make the new derivatives of tacrolimus was attempted. A carboxylic acid residue in a ring structure compound is necessary for attachment at the loading module of FkbB. Therefore, we chose several compounds that possessed a carboxylic residue, instead of DHCHC, for the precursor-directed mutasynthesis. The carboxylic acids were added to the tacrolimus production medium after 1 day cultivation before the production of tacrolimus and then after 6 days cultivation and the metabolites obtained from cultured broth with acetone extraction were analyzed by HPLC. Among the starter analogues tried, trans-4-HHA and 3-HBA increased the antifungal bioactivity of fermented broth (Fig. 5d, e). However, cis-4-HHA, 4-methylcyclohexanecarboxylic acid, trans-4-aminomethylcyclohexanecarboxylic acid, 4-hydroxymethyl-1-cyclohexanecarboxylic acid, CHC, 4-amino-cyclohexanecarboxylic acid, and isonipecotic acid did not make any difference to the bioactivity (Fig. 5f) and HPLC patterns (Fig. 6e), as compared with the additive-free control. In the case of addition of 4-HHA and 3-HBA, we found apparently increased peaks at 31 min (Fig. 6a, c) and 22.5 min (Fig. 6d), respectively, in HPLC analysis. Both peaks were simply purified by Sep-Pak C18 cartridges and HPLC and measured their mass. It had an m/z of 796.4 and 790.4 that corresponded to sodium adduct of 31-desmethoxytacrolimus and hydoxybenzoyl derivatives of tacrolimus (TC-225), respectively (Fig. 7). 31-Desmethoxytacrolimus was produced in very high amounts (about 55 mg/L) but TC-225 was produced in small amounts (about 5 mg/L). 31-Desmethoxytacrolimus was observed in cultivated broth after the addition of trans-4-HHA, but not cis-4-HHA (Fig. 6b, c). Addition of their racemic mixture (4-HHA) also clearly produced the peak without a decrease, compared with the trans-form incorporation (Fig. 6a).

HPLC chromatograms of metabolites of cultivated Streptomyces sp. GT110507 supplemented with carboxylic acids as starter unit. Supplemented carboxylic acids are cis/trans-4-HHA (a), cis-4-HHA (b), trans-4-HHA (c), 3-HBA (d), and trans-4-aminomethylcyclohexanecarboxylic acid (e). The chromatogram of e was similar with that of other precursors supplementation. The peaks of 31-desmethoxytacrolimus and TC-225 are marked by circles and star, respectively

HPLC analysis of metabolites produced by Streptomyces sp. GT1105 (a) and Streptomyces sp. GT110507 supplemented with 4-hydroxy-cyclohexanecarboxylic acid (b) and 3-HBA (c). Designated molecular mass (m/z, M + Na) was measured by LC/MS analysis using the simply purified crude metabolites from fermented broth

Identification and purification of 31-desmethoxytacrolimus

Various concentrations of racemic 4-HHA (1–100 mM) were added to the production medium to determine the optimum concentration for the tacrolimus derivatives. Although the highest level of 31-desmethoxytacrolimus production was observed at 5 mM 4-HHA, no significant differences in the level of 31-desmethoxytacrolimus productions were observed in at 1–10 mM (data not shown). However, supplementation of over 20 mM 4-HHA led to negligible production of 31-desmethoxytacrolimus. When 1 mM of 4-HHA was added, the yield of 31-desmethoxytacrolimus was about 25 % that of the tacrolimus production of Streptomyces sp.GT1105. The compound was purified as about 50 mg of a white powder containing 31-desmethoxytacrolimus from the 2.5-L of culture of the fkbO deletion mutant following the addition of 1 mM of 4-HHA. The structure of 31-desmethoxytacrolimus was verified by analysis of 13C NMR and 1H NMR through the methoxy group of 31 carbon was absent (Table S1; Figs. S1, S2, and S3). The white powder contained also desmethoxyl derivatives of ascomycin as a minor compound (about 1 mg in 10 mg of the white powder) that were highly resolved by LC/MS (Fig. 7b). These experiments provided evidence that 4-HHA instead of DHCHC was incorporated very efficiently into the PKS loading module in tcs of Streptomyces sp. GT110507.

Discussion

The tacrolimus biosynthetic gene cluster (tcs) has been identified from ATCC55098, KCTC 9225, and KCTC 11604BP by our group (Mo et al. 2011). In the previous study, tcs clusters as a 97-kb contiguous DNA represented by three overlap** fosmids was obtained (Mo et al. 2011). Analysis of this sequence revealed 19 genes designated as tcsA to fkbQ that are involved in tacrolimus biosynthesis. These genes comprise PKS, pipecolate-incorporating enzyme, and a number of post-PKS tailoring enzymes. In the biosynthesis of tacrolimus, the starter unit and C21 side chain biosynthesis have been recently resolved. C21 side chain biosynthesis requires a minimum of four genes: tcsA, tcsB, tcsC, and tcsD. Their functions are well-known and the genes are good targets for mutational biosynthesis to create new compounds (Mo et al. 2011).

The tcs gene clusters have three candidate regulators: fkbN, tcs2, and fkbO. The deletion mutants of fkbN and fkbO (constructed in Streptomyces sp. KCTC 11604BP) produced highly diminished production of tacrolimus and its derivatives (Mo et al. 2012; Fig. 3c), but the tcs2 deletion mutant did not change the production (our data, not published). We also constructed independent overexpressing strains of fkbN, tcs2, and fkbO in the GT1105 strain. The overexpression of fkbN and tcs2 did not show any apparent effect on tacrolimus production in Streptomyces sp. GT1105 (our data, not published). However, in Streptomyces sp. KCTC 11604BP, the overexpression of fkbN significantly increased the production of tacrolimus (Mo et al. 2012). The difference in overexpression may reflect the strain differences. Interestingly, overexpression of fkbO apparently increased tacrolimus production by 55–65 % (Fig. 4).

RapK, which is an FkbO homologue in the rapamycin biosynthetic machinery, was initially known to encode a pteridine-dependent dioxygenase involved in the oxidation of putative C9 hydroxy group to a ketone (Schwecke et al. 1995; Aparicio et al. 1996) or a regulator involved in the regulation of DHCHC production from shikimate (Gregory et al. 2005). However, recent evidence has abrogated the role of FkbO as a regulator (Andexer et al. 2011). The function of RapK and FkbO (from an ascomycin producer) is related to the starter unit (DHCHC) biosynthesis of tricyclo compounds like tacrolimus and rapamycin (Andexer et al. 2011). Interestingly, rapK and its homologue fkbO in the ascomycin biosynthetic gene pathway encode chorismate hydrolase as a member of a new family of enzymes acting on chorismate, as verified by in vitro enzymatic analysis and in vivo genetic complementation experiments (Andexer et al. 2011). Accordingly, the increase in tacrolimus production by overexpression of fkbO may come from the enrichment of the final starter unit, DHCHC, but not from any regulation. Therefore, we expect that tacrolimus production may be increased by adding shikimate as a DHCHC precursor to the medium. However, the addition of shikimate did not increase the production (data not shown). Therefore, the increase by fkbO overexpression may actually be due to the efficient change from chorismate to DCDC by overexpressed FkbO. It is possible that the dechorismatation step by FkbO is a limiting step in tacrolimus production.

We also explored the production of tacrolimus by the new compounds using the DHCHC analogue with the fkbO deletion mutant, Streptomyces sp. GT110507. In general, PCR-targeting methods (Gust et al. 2003) possibly show a polar effect in mutated gene clusters caused by the apramycin resistance cassette (aac(3)IV-oriT). But, our deletion mutant strains of fkbO did not show any polar effects. The promoter (p apr) in the deletion cassette can efficiently drive the expression of downstream genes (fkbP, fkbA, etc.) of the mutated sites. Therefore, double crossing over of several gene mutants can easily occur with PCR targeting without a polar effect. Streptomyces sp. GT110507 produced a trace amount of tacrolimus that was detected only by LC/MS and not by HPLC (detection limit is below 0.1 mg/L). The trace amount of tacrolimus possibly reflects that the trace amount of DHCHC present in the complex medium used and tcs in Streptomyces sp. GT110507 is still working.

We investigated new metabolites produced by several candidate starter carboxylic acids instead of DHCHC. Adding 4-HHA and 3-HBA into the culture of Streptomyces sp. GT110507 increased the bioactivity against fungi (Fig. 5d–f). However, 4-amino-cyclohexanecarboxylic acid, CHC, 4-hydroxybenzoic acid, isonipecotic acid, and 4-methylcyclohexanecarboxylic acid did not make any difference to bioactivity (Fig. 5f) and metabolites (Fig. 6e) as compared with the no addition control. Especially, 4-HHA (racemic form) was very well incorporated (Fig. 6a) into tacrolimus skeleton, but its cis-form did not incorporate (Fig. 6b) and compete with the trans-form. As a resulting compound, 31-desmethoxyl tacrolimus produced about 25 % of the yield of tacrolimus, making it potentially useful in industrial-scale production. 31-Desmethoxy analogues of ascomycin and dihydrotacrolimus were also produced by 4-HHA directed mutasynthesis (Fig. 7).

The incorporation properties of starter unit homologues of DHCHC into the tacrolimus skeleton were somewhat different from that of rapamycin. In rapamycin biosynthesis, the rapK mutant (BIOT-4010) produced small amounts of BC325 (Fig. 1) and the addition of 3-HBA into the mutant culture increased the production of BC325 (Andexer et al. 2011). However, in our experiments, the fkbO mutant did not produce any tacrolimus derivatives like BC325 but produced trace amount of tacrolimus. The addition of nonhydroxylated starter unit acids like CHC and cyclohex-1-enecarboxylic acid to the growing rapK, rapI, rapJ, rapM, rapN, rapO, rapQ, and rapL excised mutant resulted in the production of pre-rapamycin derivatives containing the hydroxylated starter unit group like 39-desmethoxyl pre-rapamycin and 39-desmethyl 40-dehydroxyl pre-rapamycin, respectively (Gregory et al. 2005). Therefore, rapamycin producers have the catalytic ability for the hydroxylation of added starter acid and the downstream PKS could accept a nonhydroxylated acid. However, the tacrolimus producer did not accept any of the nonhydroxylated forms of the starter acids we tested. Hydroxylated acids of 4-HHA and 3-HBA were only accepted in Streptomyces sp. GT110507. Those results indicate that the tacrolimus producer Streptomyces sp. GT1105 strain is more intolerant of the starter unit acid than the rapamycin producer Streptomyces hygroscopicus subsp. hygroscopicus. Recently, the United States Food and Drug Administration mandated a “black box” warning label for the topical use of tacrolimus and pimecrolimus because of the increased possibility of cancer during long-term patient use. Therefore, it is necessary that the development of new drugs of tacrolimus or ascomycin derivatives show a diminished risk of cancer occurrence by the changing of pharmacodynamics and pharmacokinetics. Through precursor-directed mutasynthesis, new compounds can be created for drugs to treat many diseases related to the immune mechanism.

Tacrolimus analogues like 31-desmethoxytacrolimus and TC-225 may be good candidate new drugs. We hope that our report will spur the creation of new tacrolimus or ascomycin derivatives using biosynthesis technology.

References

Aldape RA, Futer O, DeCenzo MT, Jarrett BP, Murcko MA, Livingston DJ (1992) Charged surface residues of FKBP12 participate in formation of the FKBP12–FK506–calcineurin complex. J Biol Chem 267:16029–16032

Andexer JN, Kendrew SG, Nur-e-Alam M, Lazos O, Foster TA, Zimmermann AS, Warneck TD, Suthar D, Coates NJ, Koehn FE, Skotnicki JS, Carter GT, Gregory MA, Martin CJ, Moss SJ, Leadlay PF, Wilkinson B (2011) Biosynthesis of the immunosuppressants FK506, FK520, and rapamycin involves a previously undescribed family of enzymes acting on chorismate. Proc Natl Acad Sci U S A 108:4776–4781

Aparicio JF, Molnar I, Schwecke T, Konig A, Haydock SF, Khaw LE, Staunton J, Leadlay PF (1996) Organization of the biosynthetic gene cluster for rapamycin in Streptomyces hygroscopicus: analysis of the enzymatic domains in the modular polyketide synthase. Gene 169:9–16

Armistead DM, Badia MC, Deininger DD, Duffy JP, Saunders JO, Tung RD, Thomson JA, DeCenzo MT, Futer O, Livingston DJ, Murcko MA, Yamashita MM, Navia MA (1995) Design, synthesis and structure of non-macrocyclic inhibitors of FKBP12, the major binding protein for the immunosuppressant FK506. Acta Crystallogr D Biol Crystallogr 51:522–528

Driggers EM, Hale SP, Lee J, Terrett NK (2008) The exploration of macrocycles for drug discovery—an underexploited structural class. Nat Rev Drug Discov 7:608–624

Goranovic D, Kosec G, Mrak P, Fujs S, Horvat J, Kuscer E, Kopitar G, Petkovic H (2010) Origin of the allyl group in FK506 biosynthesis. J Biol Chem 285:14292–14300

Gregory MA, Petkovic H, Lill RE, Moss SJ, Wilkinson B, Gaisser S, Leadlay PF, Sheridan RM (2005) Mutasynthesis of rapamycin analogues through the manipulation of a gene governing starter unit biosynthesis. Angew Chem Int Ed Engl 44:4757–4760

Gust B, Challis GL, Fowler K, Kieser T, Chater KF (2003) PCR-targeted Streptomyces gene replacement identifies a protein domain needed for biosynthesis of the sesquiterpene soil odor geosmin. Proc Natl Acad Sci U S A 100:1541–1546

Huang S, Houghton PJ (2003) Targeting mTOR signaling for cancer therapy. Curr Opin Pharmacol 3:371–377

Hultsch T, Muller KD, Meingassner JG, Grassberger M, Schopf RE, Knop J (1998) Ascomycin macrolactam derivative SDZ ASM 981 inhibits the release of granule-associated mediators and of newly synthesized cytokines in RBL 2H3 mast cells in an immunophilin-dependent manner. Arch Dermatol Res 290:501–507

Kennedy J (2008) Mutasynthesis, chemobiosynthesis, and back to semi-synthesis: combining synthetic chemistry and biosynthetic engineering for diversifying natural products. Nat Prod Rep 25:25–34

Khaw LE, Bohm GA, Metcalfe S, Staunton J, Leadlay PF (1998) Mutational biosynthesis of novel rapamycins by a strain of Streptomyces hygroscopicus NRRL 5491 disrupted in rapL, encoding a putative lysine cyclodeaminase. J Bacteriol 180:809–814

Kieser T, Bibb MJ, Buttner MJ, Chater KF, Hopwood DA (2000) Practical Streptomyces genetics: a laboratory manual. John Innes Centre, Norwich

Kino T, Hatanaka H, Miyata S, Inamura N, Nishiyama M, Yajima T, Goto T, Okuhara M, Kohsaka M, Aoki H (1987) FK-506, a novel immunosuppressant isolated from a Streptomyces. II. Immunosuppressive effect of FK-506 in vitro. J Antibiot (Tokyo) 40:1256–1265

Lowden PA, Bohm GA, Metcalfe S, Staunton J, Leadlay PF (2004) New rapamycin derivatives by precursor-directed biosynthesis. ChemBioChem 5:535–538

MacNeil DJ, Gewain KM, Ruby CL, Dezeny G, Gibbons PH, MacNeil T (1992) Analysis of Streptomyces avermitilis genes required for avermectin biosynthesis utilizing a novel integration vector. Gene 111:61–68

Mo S, Kim DH, Lee JH, Park JW, Basnet DB, Ban YH, Yoo YJ, Chen SW, Park SR, Choi EA, Kim E, ** YY, Lee SK, Park JY, Liu Y, Lee MO, Lee KS, Kim SJ, Kim D, Park BC, Lee SG, Kwon HJ, Suh JW, Moore BS, Lim SK, Yoon YJ (2011) Biosynthesis of the allylmalonyl-CoA extender unit for the FK506 polyketide synthase proceeds through a dedicated polyketide synthase and facilitates the mutasynthesis of analogues. J Am Chem Soc 133:976–985

Mo S, Yoo YJ, Ban YH, Lee SK, Kim E, Suh JW, Yoon YJ (2012) Roles of fkbN in positive regulation and tcs7 in negative regulation of FK506 biosynthesis in Streptomyces sp. strain KCTC 11604BP. Appl Environ Microbiol 78:2249–2255

Parsons WH, Sigal NH, Wyvratt MJ (1993) FK-506—a novel immunosuppressant. Ann N Y Acad Sci 685:22–36

Price RD, Yamaji T, Yamamoto H, Higashi Y, Hanaoka K, Yamazaki S, Ishiye M, Aramori I, Matsuoka N, Mutoh S, Yanagihara T, Gold BG (2005) FK1706, a novel non-immunosuppressive immunophilin: neurotrophic activity and mechanism of action. Eur J Pharmacol 509:11–19

Reeves CD, Chung LM, Liu Y, Xue Q, Carney JR, Revill WP, Katz L (2002) A new substrate specificity for acyl transferase domains of the ascomycin polyketide synthase in Streptomyces hygroscopicus. J Biol Chem 277:9155–9159

Regentin R, Cadapan L, Ou S, Zavala S, Licari P (2002) Production of a novel FK520 analog in Streptomyces hygroscopicus: improving titer while minimizing impurities. J Ind Microbiol Biotechnol 28:12–16

Ritacco FV, Graziani EI, Summers MY, Zabriskie TM, Yu K, Bernan VS, Carter GT, Greenstein M (2005) Production of novel rapamycin analogs by precursor-directed biosynthesis. Appl Environ Microbiol 71:1971–1976

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Schwecke T, Aparicio JF, Molnar I, Konig A, Khaw LE, Haydock SF, Oliynyk M, Caffrey P, Cortes J, Lester JB (1995) The biosynthetic gene cluster for the polyketide immunosuppressant rapamycin. Proc Natl Acad Sci U S A 92:7839–7843

Sedrani R, Cottens S, Kallen J, Schuler W (1998) Chemical modification of rapamycin: the discovery of SDZ RAD. Transplant Proc 30:2192–2194

Shafiee A, Chen TS, Arison BS, Dumont FJ, Colwell L, Kaplan L (1993) Enzymatic synthesis and immunosuppressive activity of novel desmethylated immunomycins (ascomycins). J Antibiot (Tokyo) 46:1397–1405

Wan X, Shen N, Mendoza A, Khanna C, Helman LJ (2006) CCI-779 inhibits rhabdomyosarcoma xenograft growth by an antiangiogenic mechanism linked to the targeting of mTOR/Hif-1alpha/VEGF signaling. Neoplasia 8:394–401

Wilson DJ, Patton S, Florova G, Hale V, Reynolds KA (1998) The shikimic acid pathway and polyketide biosynthesis. J Ind Microbiol Biotechnol 20:299–303

Acknowledgments

This research was financially supported by the Ministry of Knowledge Economy and Korea Institute for Advancement of Technology through the Research and Development for Regional Industry (A001100167).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 158 kb)

Rights and permissions

About this article

Cite this article

Kim, D.H., Ryu, J.H., Lee, K.S. et al. Mutational biosynthesis of tacrolimus analogues by fkbO deletion mutant of Streptomyces sp. KCTC 11604BP. Appl Microbiol Biotechnol 97, 5881–5892 (2013). https://doi.org/10.1007/s00253-013-4716-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00253-013-4716-1