Abstract

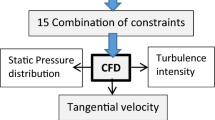

In order to meet the demand of industrial production, an axial separator for oil-water separation is proposed. The separator uses the pattern of multi-stage separation, and it is divided into two chambers by two swirl impellers. The oil phase flows out through three Light Phase Outlet (LPO) at the center of the impeller hub, meanwhile the water phase flows out through Heavy Phase Outlet (HPO). An experimental platform was built to verify the feasibility of multi-stage separation. The Mixture model and Reynolds stress model was used to simulate the separation process, and the numerical results had a well agreement with experimental results. The effects of the diameter of cylindrical section, length of conical section and length of separation chamber on the separation performance were studied. The results show that: changing the diameter of cylindrical section has greatest impact on separation performance. The separation efficiency and pressure drop first increase and then decrease with increase of primary conical section length. With increase of second conical section length, the separation performance has been increasing. If it only looks at the relationship between pressure drop and separation efficiency, then there is a pressure drop to maximize the separation efficiency. Changing the diameter of cylindrical section can adjust the flow split LPOs. Increasing the length of second conical section can increase the split ratio of LPO3, but it has almost no effect on the total split ratio of LPOs. the value of structure is determined and the efficiency of separator exceeds 93 %.

Similar content being viewed by others

References

Bowers B, Peak Process IE, Brownlee RF, Schrenkel PJ (2000) Development of a downhole oil-water separation and reinjection system for offshore application. SPE J 15:639–648

Zeng X, Zhao L, Fan G, Yan C (2021) Experimental study on the design of light phase outlets for a novel axial oil-water separator. Chem Eng Res Des 165:308–319. https://doi.org/10.1016/j.cherd.2020.11.008

Peachey B, Solanki R, Zahacy SC, Piers TA (1998) Downhole Oil/Water separation moves into high gear. J Can Pet Technol 37:34–41

Bhaskar KU, Murthy YR, Raju MR, Tiwari S, Srivastava JK, Ramakrishnan N (2007) CFD simulation and experimental validation studies on hydrocyclone. Miner Eng 20:60–71. https://doi.org/10.1016/j.mineng.2006.04.012

Noroozi S, Hashemabadi SH (2009) CFD simulation of inlet design effect on deoiling hydrocyclone separation efficiency. Chem Eng Technol 32:1885–1893. https://doi.org/10.1002/ceat.200900129

Saidi M, Maddahian R, Farhanieh B (2012) Numerical investigation of cone angle effect on the flow field and separation efficiency of deoiling hydrocyclones. Heat Mass Transf 49:247–260. https://doi.org/10.1007/s00231-012-1085-8

Young G, B A, Wakley WD, Taggart DL, Andrews SL, Worrell JR (1994) Oil-water separation using hydrocyclones: An experimental search for optimum dimensions. J Pet Sci Eng 11:37–50

Wang J, Bai Z, Yang Q, Fan Y, Wang H (2016) Investigation of the simultaneous volumetric 3-component flow field inside a hydrocyclone. Sep Purif Technol 163:120–127. https://doi.org/10.1016/j.seppur.2016.02.022

Schütz S, Gorbach G, Piesche M (2009) Modeling fluid behavior and droplet interactions during liquid–liquid separation in hydrocyclones. Chem Eng Sci 64:3935–3952. https://doi.org/10.1016/j.ces.2009.04.046

Dirkzwager M (1996) A new axial cyclone design for fluid-fluid separation. PhD Thesis, Delft University of TechnologyDelft

van C, Laurens, Mudde R, Frank, Slot J, Hoeijmakers H (2012) A numerical and experimental survey of a liquid-liquid axial cyclone. Int J Chem Reactor Eng 10. https://doi.org/10.1515/1542-6580.3003

Bai Z-s, Wang H-l, Tu S-T (2009) Experimental study of flow patterns in deoiling hydrocyclone. Miner Eng 22:319–323. https://doi.org/10.1016/j.mineng.2008.09.003

Hamza JE, Al-Kayiem HH, Lemma TA (2020) Experimental investigation of the separation performance of oil/water mixture by compact conical axial hydrocyclone. Therm Sci Eng Prog 17:100358. https://doi.org/10.1016/j.tsep.2019.100358

Husveg T, Rambeau O, Drengstig T, Torleiv B (2007) Performance of a deoiling hydrocyclone during variable flow rates. Miner Eng 20:368–379. https://doi.org/10.1016/j.mineng.2006.12.002

Zhou N, Gao Y, An W, Yang M (2010) Investigation of velocity field and oil distribution in an oil–water hydrocyclone using a particle dynamics analyzer. Chem Eng J 157:73–79. https://doi.org/10.1016/j.cej.2009.10.049

Shi S-y, Xu J-y (2015) Flow field of continuous phase in a vane-type pipe oil–water separator. Exp Thermal Fluid Sci 60:208–212. https://doi.org/10.1016/j.expthermflusci.2014.09.011

Murphy S, Delfos R, Pourquié MJBM, Olujić Ž, Jansens PJ, Nieuwstadt FTM (2007) Prediction of strongly swirling flow within an axial hydrocyclone using two commercial CFD codes. Chem Eng Sci 62:1619–1635. https://doi.org/10.1016/j.ces.2005.10.031

Liu M, Chen J, Cai X, Han Y, **ong S (2018) Oil–water pre-separation with a novel axial hydrocyclone. Chin J Chem Eng 26:60–66. https://doi.org/10.1016/j.cjche.2017.06.021

Wang Z, Yi M, ** Y (2011) Simulation and experiment of flow field in axial-flow hydrocyclone. Chem Eng Res Des 89:603–610. https://doi.org/10.1016/j.cherd.2010.09.004

Jiang M, Chen D, Chen S, Xu L, Zhao L (2009) Comparative experimental research on oily wastewater treatment by hydrocyclones in series. special track within iCBBE2009 6:1–4

Si H (2005) Numerical simulation of oil-water numerical simulation of oil-water hydrocyclone using reynolds-stress model for eulerian multiphase flows. Can J Chem Eng 83:829–834

Kharoua N, Khezzar L, Nemouchi Z (2010) Hydrocyclones for de-oiling applications—A review. Pet Sci Technol 28:738–755. https://doi.org/10.1080/10916460902804721

Ba ZS, Wang HL (2006) Numerical simulation of the separating performance of hydrocyclones. Chem Eng Technol 29:1161–1166. https://doi.org/10.1002/ceat.200600102

Paladino EE, NGC, Schwenk L (2005) CFD analysis of the transient flow in a low-oil concentration hydrocyclone. Proc of the Annual Meeting: AIChE 646–657

Dyakowski TW, R,A (1993) Modeling turbulent flow with-in a small-diameter hydrocyclone. Chem Eng Sci 48:1143–1152

Lu Y, Zhou l, Shen X (2001) Different turbulence models for simulating a liquid-liquid hydrocyclone. J Tsinghua Univ (Sci Technol) 41:105–109

Yang I, Shin H, Kim CB, Kim TH (2004) A three-dimensional simulation of a hydrocyclone for the sludge separation in water purifying plants and comparison with experimental data. Miner Eng 17:637–641. https://doi.org/10.1016/j.mineng.2003.12.010

Zeng X, Zhao L, Zhao W, Hou M, Zhu F, Fan G, Yan C (2020) Experimental study on a novel axial separator for oil–water separation. Ind Eng Chem Res 59:21177–21186. https://doi.org/10.1021/acs.iecr.0c03913

Zeng X, Yan C, Fan G (2020) Experimental study on two different gas-liquid separators under different flow patterns. 2020 International Conference on Nuclear Engineering collocated with the ASME 2020 Power Conference

Kline SJ (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

Zeng X, Zhao L, Zhao W, Hou M, Zhu F, Fan G, Yan C (2021) Experimental study on a compact axial separator with conical tube for liquid-liquid separation. Sep Purif Technol 257:117904. https://doi.org/10.1016/j.seppur.2020.117904

Zeng X, Fan G, Xu J, Liu A, Xu Y, Yan C (2020) Experimental study on a new gas–liquid separator for a wide range of gas volume fraction. Chem Eng Res Des 160:561–570. https://doi.org/10.1016/j.cherd.2020.06.004

Wang G, Yan C, Fan G, Wang J, Xu J, Zeng X, Liu A (2019) Experimental study on a swirl-vane separator for gas–liquid separation. Chem Eng Res Des 151:108–119. https://doi.org/10.1016/j.cherd.2019.09.003

Noroozi S, Hashemabadi SH (2011) CFD analysis of inlet chamber body profile effects on de-oiling hydrocyclone efficiency. Chem Eng Res Des 89:968–977. https://doi.org/10.1016/j.cherd.2010.11.017

Zeng X, Xu Y, Zhao L (2021) Numerical investigation on axial liquid-liquid separators with different swirl chambers. Chem Eng Process Process Intensif 161:1–11

Cai B, Wang J, Sun L, Zhang N, Yan C (2014) Experimental study and numerical optimization on a vane-type separator for bubble separation in TMSR. Prog Nucl Energy 74:1–13. https://doi.org/10.1016/j.pnucene.2014.02.007

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, L., Zeng, X., Zhao, W. et al. Structural optimization for an axial oil‐water separator with multi‐stage separation. Heat Mass Transfer 57, 1949–1963 (2021). https://doi.org/10.1007/s00231-021-03084-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-021-03084-z