Abstract

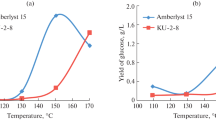

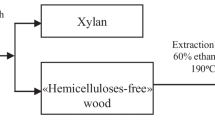

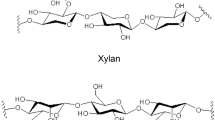

For the first time, it is proposed to combine the environmentally friendly heterogeneous catalytic processes of wood hemicelluloses hydrolysis and peroxide delignification of «hemicellulose-free» wood for the biorefinery of birch wood into microcrystalline, microfibrillated, and nanocrystalline celluloses, xylose, and sorbents. The use of the solid acid catalyst ZrO2/SO42− for the hydrolysis of birch-wood hemicelluloses at a temperature of 150 °C makes it possible to obtain xylose with a yield of 72.5% from the weight of hemicelluloses. The optimal conditions for peroxide delignification of «hemicellulose-free» birch wood in a «formic acid–water» medium over TiO2 catalyst, which ensure a high yield of microcrystalline cellulose (41.2% from weight of wood), were established. By sulfuric acid hydrolysis and ultrasonic treatment of microcrystalline cellulose, samples of microfibrillated and nanocrystalline celluloses were produced. Adsorbents with high sorption activity were obtained from organosolv lignin formed as a side product of peroxide delignification of birch lignocellulose. The birch biorefinery products were characterized by Fourier transform infrared spectroscopy, X-ray diffractometry, scanning electron microscopy, gel permeation chromatography, 31P nuclear magnetic resonance, dynamic light scattering, as well as chemical and elemental analysis.

Similar content being viewed by others

References

ASTM D1795 (2013) Standard test method for intrinsic viscosity of cellulose, ASTM International, West Conshohocken, PA

Cao Y, Chen SS, Zhang S, Sik Ok Y, Matsagar BM, Wu KCW, Tsang DCW (2019) Advances in lignin valorization towards bio-based chemicals and fuels: Lignin biorefinery. Biores Technol 291:121878. https://doi.org/10.1016/j.biortech.2019.121878

Charreau H, Foresti ML, Va ́zquez A, (2013) Nanocellulose patents trends: a comprehensive review on patents on cellulose nanocrystals, microfibrillated and bacterial cellulose. Recent Pat Nanotechnol 7(1):56–80. https://doi.org/10.2174/1872210511307010056

Chemin M, Wirotius AL, Ham-Pichavant F, Chollet G, Da Silva PD, Petit-Conil M, Cramail H, Grelier S (2015) Well-defined oligosaccharides by mild acidic hydrolysis of hemicelluloses. Eur Polymer J 66:190–197. https://doi.org/10.1016/j.eurpolymj.2015

Cherubini F (2010) The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers Manage 51:1412–1421. https://doi.org/10.1016/j.enconman.2010.01.015

Corrêa AC, Carmona VB, Simão JA, Galvani F, Marconcini JM, Mattoso LHC (2019) Cellulose nanocrystals from fibers of macauba (acrocomia aculeata) and gravata (bromelia balansae) from brazilian pantanal. Polymers 11(11):1785. https://doi.org/10.3390/polym11111785

Degirmenci V, Uner D, Cinlar B, Shanks BH, Yilmaz A, van Santen RA, Hensen EJM (2011) Sulfated zirconia modified SBA-15 catalysts for cellobiose hydrolysis. Catal Lett 141:33–42. https://doi.org/10.1007/s10562-010-0466-1

Ditzel FI, Prestes E, Carvalho BM, Demiate IM, Pinheiro LA (2017) Nanocrystalline cellulose extracted from pine wood and corncob. Carbohydr Polym 157:1577–1585. https://doi.org/10.1016/j.carbpol.2016.11

Du H, Liu W, Zhang M, Si Ch, Zhang X, Li B (2019) Cellulose nanocrystals and cellulose nanofibrils based hydrogels for biomedical applications. Carbohydr Polym 209:130–144. https://doi.org/10.1016/j.carbpol.2019.01.020

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. In: Salih S (ed) Fourier transform - materials analysis. InTech. https://doi.org/10.5772/35482

Garyntseva NV, Sudakova IG, Kuznetsov BN (2011) Properties of enterosorbents obtained from acetic acid lignins of abies, aspen and birch wood. J Sib Fed Univ Chem 2(4):121–126

Garyntseva NV, Sudakova IG, Chudina AI, Malyar YuN, Kuznetsov BN (2019) Optimization of the process of abies wood peroxide delignification in the medium “formic acid-water” in the presence of TiO2 catalyst. J Sib Fed Univ Chem 12(4):522–535. https://doi.org/10.17516/1998-2836-0148

Gromov NV, Medvedeva TB, Pestunov AV, Taran OP (2018) The production of formic acid from polysaccharides and biomass via one-pot hydrolysis-oxidation in the presence of Mo-V-P heteropoly acid catalyst. J Sib Fed Univ Chem 11(1):56–71. https://doi.org/10.17516/1998-2836-0058

Hindi SSZ (2017) Nanocrystalline cellulose: synthesis from pruning waste of Zizyphusspina-christi and characterization. Nanosci Nanotechnol Res 4(3):106–114. https://doi.org/10.12691/nnr-4-3-4

Jasmani L, Adnan Sh (2017) Preparation and characterization of nanocrystalline cellulose from Acacia mangium and its reinforcement potential. Carbohydr Polym 161:166–171. https://doi.org/10.1016/j.carbpol.2016.12.061

Jasmani L, Thielemans W (2018) Preparation of nanocellulose and its potential application. Forest Res 7:222. https://doi.org/10.4172/2168-9776.1000222

Kargarzadeh H, Ahmad I, Abdullah I, Dufresne A, Zainudin SY, Sheltami RM (2012) Effects of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenafbast fibers. Cellulose 19:855–866. https://doi.org/10.1007/s10570-012-9684-6

Kuznetsov BN, Sudakova IG, Celzard A, Garyntseva NV, Ivanchenko NM, Petrov AV (2011) Binding properties of lignins obtained at oxidative delignifiation of wood and straw. J Sib Fed Univ Chem 1(4):3–10

Kuznetsov BN, Yatsenkova OV, Chudina AI, Skripnikov AM, Kozlova SA, Garyntseva NV, Chesnokov NV (2014) Influence of mechanical and chemical activation of microcrystalline cellulose on its structure and reactivity in hydrolysis with solid acid catalyst SBA-15. J Sib Fed Univ Chem 7(1):122–133

Kuznetsov BN, Malyar YuN, Kuznetsova SA, Grishechko LI, Kazachenko AS, Levdansky AV, Pestunov AV, Boyandin AN, Celzard A (2016) Isolation, study and application of organosolv lignins (review). J Sib Fed Univ Chem 4(9):454–482. https://doi.org/10.17516/1998-2836-2016-9-4-454-482

Kuznetsov BN, Sudakova IG, Garyntseva NV, Djakovitch L, Pinel C (2017) Kinetic studies and optimization of abies wood fractionation by hydrogen peroxide under mild conditions with TiO2 catalyst. Reac Kinet Mech Cat 120:81–94. https://doi.org/10.1007/s11144-016-1100-z

Kuznetsov BN, Vasilyeva NY, Kazachenko AS, Levdansky VA, Kondrasenko AA, Malyar Y, Skvortsova GP, Lutoshkin MA (2020) Optimization of the process of abies ethanol lignin sulfation by sulfamic acid – urea mixture in 1,4-dioxane medium. Wood Sci Technol 54:365–381. https://doi.org/10.1007/s00226-020-01157-6

Kuznetsov BN, Sudakova IG, Garyntseva NV, Tarabanko VE, Yatsenkova OV, Djakovitch L, Rataboul F (2021a) Processes of catalytic oxidation for the production of chemicals from softwood biomass. Catal Today 375:132–144. https://doi.org/10.1016/j.cattod.2020.05.044

Kuznetsov BN, Sharypov VI, Baryshnikov SV, Miroshnikova AV, Taran OP, Yakovlev VA, Lavrenov AV, Djakovitch L (2021b) Catalytic hydrogenolysis of native and organosolv lignins of aspen wood to liquid products in supercritical ethanol medium. Catal Today 379:114–123. https://doi.org/10.1016/j.cattod.2020.05.048

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose –Its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Lepetit A, Drolet R, Tolnai B, Montplaisir D, Lucas R, Zerrouki R (2017) Microfibrillated cellulose with sizing for rein-forcing composites with LDPE. Cellulose 24(10):4303–4312. https://doi.org/10.1007/s10570-017-1429-0

Markelov DA, Nitsak OV, Gerashchenko II (2008) Comparative study of the adsorption activity of medical sorbents. Pharm Chem J 42(7):30–33. https://doi.org/10.30906/0023-1134-2008-42-7-30-33

Melero JA, Grieken R, Morales G (2006) Advances in the synthesis and catalytic applications of organosulfonic-functionalized mesostructured materials. Chem Rev 106:3790–3812. https://doi.org/10.1021/cr050994h

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J (2011) Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 40:3941–3994. https://doi.org/10.1039/C0CS00108B

Nascimento SA, Rezende CA (2018) Combined approaches to obtain cellulose nanocrystals, nanofibrils and fermentable sugars from elephant grass. Carbohydr Polym 180:38–45. https://doi.org/10.1016/j.carbpol.2017.09

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron x-ray and neutron fiber diffraction. J Am Chem Soc 124:9074–9082. https://doi.org/10.1021/ja0257319

Park S, Baker JO, Himmel ME, Parilla PA, Jonson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on integrating cellulose performance. Biotechnol Biofuels 3:10. https://doi.org/10.1186/1754-6834-3-10

Shen X, Sun R (2021) Recent advances in lignocellulose prior-fractionation for biomaterials, biochemicals, and bioenergy. Carbohyd Polym 261:117884. https://doi.org/10.1016/j.carbpol.2021.11

Shi Z, Xu G, Deng J, Dong M, Murugadoss V, Liu Ch, Shao Q, Wu S, Guo Z (2019) Structural characterization of lignin from D sinicus by FTIR and NMR techniques. Green Chem Lett Rev 12(3):235–243. https://doi.org/10.1080/17518253.2019.1627428

Sjöström E, Alern R (1999) Analytical methods of wood chemistry pul** and papermaking. Springer-Verlag, Berlin

Takagaki A, Nishimura M, Nishimura S, Ebitani K (2011) Hydrolysis of sugars using magnetic silica nanoparticles with sulfonic acid groups. Chem Lett 40:1195–1197. https://doi.org/10.1246/cl.2011.1195

Takkellapati S, Li T, Gonzalez MA (2018) An overview of biorefinery-derived platform chemicals from a cellulose and hemicellulose biorefinery. Clean Techn Environ Policy 20:1615–1630. https://doi.org/10.1007/s10098-018-1568-5

Vilcocq L, Castilho PC, Carvalheiro F, Duarte LC (2014) Hydrolysis of oligosaccharides over solid acid catalysts: a review. Chem Sus Chem 7:1010–1019. https://doi.org/10.1002/cssc.201300720

Wu C, Bing L, Li S, Yu D, Wang D (2016) Effect of coagulating agents on lignin and oligosaccharide contents in pre-hydrolysis liquor obtained in the production of dissolving pulp from poplar residual slabs. Bio Res 11(1):87–94. https://doi.org/10.15376/biores.11.1.87-94

Yatsenkova O, Chudina AI, Skripnikov AM, Chesnokov NV, Kuznetsov BN (2015) The influence of sulfuric acid catalyst concentration on hydrolysis of birch wood hemicelluloses. J Sib Fed Univ Chem 8(2):211–221. https://doi.org/10.17516/1998-2836-2015-8-2-211-221

Zhou S, Liu P, Wang M, Zhao H, Yang J, Xu F (2016) Sustainable, reusable, and superhydrophobic aerogels from micro-fibrillated cellulose for highly effective oil/water separation. ACS Sustainable Chem Eng 4(12):6409–6416. https://doi.org/10.1021/acssuschemeng.6b01075

Acknowledgements

The FTIR, NMR, GPC, SEM, and XRD investigations were carried out on the equipment of the Krasnoyarsk Territorial Center for Collective Use, Krasnoyarsk Scientific Center, Siberian Branch of the Russian Academy of Sciences.

Funding

This study was supported by the Russian Science Foundation, project no. 21–13-00250. https://rscf.ru/project/21-13-00250.

Author information

Authors and Affiliations

Contributions

Conceptualization: BNK; methodology: BNK, IGS, and NVG; formal analysis and investigations: IGS, NVG, AVP, AMS and EVG; writing an original draft: NVG; writing a review and editing: BNK; funding acquisition: BNK.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kuznetsov, B.N., Sudakova, I.G., Garyntseva, N.V. et al. Birch wood biorefinery into microcrystalline, microfibrillated, and nanocrystalline celluloses, xylose, and adsorbents. Wood Sci Technol 57, 173–196 (2023). https://doi.org/10.1007/s00226-022-01443-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-022-01443-5