Abstract

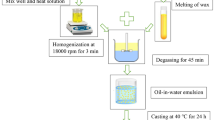

The overall goal of this research was to develop plant protein-based lipid composite films by examining the effect of shear (mechanical shear; MS vs. high pressure shear; HPS) and type of legume protein isolates (pea, lentil, soy, and faba bean). Compared to MS, HPS emulsions had smaller droplet size, and HPS emulsions from pea and lentil were more viscous than soy and faba bean. The HPS films were lighter and more green and yellow in colour compared to MS films. HPS also improved the mechanical properties of the films resulting in higher tensile and puncture strength for pea and soy and higher tensile elongation and puncture deformation for most of the legumes. There was an inverse relationship between legumes where overall stronger and less flexible films were prepared from pea and soy, and vice versa from lentil and faba bean. HPS resulted in pea and soy films with less swelling ability and higher water vapour permeability (WVP), indicative of a poorer moisture barrier when homogenized this way. The MS films had similar WVP regardless of legume type, while under HPS it was the lowest for faba bean and highest for soy, despite the high swelling ability for both legumes. In short, pea, lentil, and faba bean protein isolates prepared emulsion films with good mechanical properties and water resistance, suggesting the potential to replace soy as edible packaging materials. HSP films had better mechanical attributes but poorer vapor barrier properties then those produced using MS.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available on request from the corresponding author, MTN.

References

Fortune Business Insights (2023) Edible packaging market size, share & COVID-19 impact analysis, by material (protein, polysaccharides, lipid, and others), by product type (films, coatings, spoon & fork, and others), by end use (food & beverage {fresh food, bakery & confectionary, dairy products, other}, and pharmaceuticals), and regional forecasts, 2023–2030 (Report ID: FBI107722). https://www.fortunebusinessinsights.com/edible-packaging-market-107722

Denavi GA, Perez-Mateos M, Ahem MC, Montero P, Mauri AN, Gomez-Guillen MC (2009) Structural and functional properties of soy protein isolate and cod gelatin blend films. Food Hydrocolloids 23:2094–2101

Dhall RK (2013) Advances in edible coatings for fresh fruits and vegetables: a review. Crit Rev Food Sci Nutr 53(5):435–450

Ramos ÓL, Pereira JO, Silva SI, Fernandes JC, Franco MI, Lopes-da-Silva JA, Pintado ME, Malcata FX (2012) Evaluation of antimicrobial edible coatings from a whey protein isolate base to improve the shelf life of cheese. J Dairy Sci 95:6282–6292

Zhang H, Mittal G (2010) Biodegradable protein-based films from plant resources: a review. Environ Prog Sustainable Energy 29(2):203–220

Falguera V, Quintero JP, Jimenez A, Munoz JA, Ibarz A (2011) Edible films and coatings: structures, active functions and trends in their use. Trends Food Sci Technol 22:292–303

Hopkins EJ, Chang C, Lam RSH, Nickerson MT (2015) Effects of flaxseed oil concentration on the performance of a soy protein isolate-based emulsion-type film. Food Res Int 67:418–425

Brandenburg AH, Weller CL, TestinR F (1993) Edible films and coatings from soy protein. J Food Sci 58:1086–1089

Hopkins EJ, Stone AK, Wang J, Korber DR, Nickerson MT (2019) Effect of glycerol on the physicochemical properties of films based on legume protein concentrates: a comparative study. J Texture Stud 50:539–546

AOAC (2005) Official methods of analysis, 16th edn. Association of Official Analytical Chemists, Washington DC

Kato A, Nakai S (1980) Hydrophobicity determined by a fluorescence probe method and its correlation with surface properties of proteins. Biochim Biophys Acta Protein Struct 624(1):13–20

Gontard N, Guilbert S, Cuq JL (1992) Edible wheat gluten films: influence of the main process variables on film properties using response surface methodology. J Food Sci 57:190–195

Chang C, Nickerson MT (2013) Effect of plasticizer-type and genipin on the mechanical, optical, and water vapor barrier properties of canola protein isolate-based edible films. Eur Food Res Technol 238:35–46

Gennadios A, Weller CL, Gooding CH (1994) Measurement errors in water vapor permeability of highly permeable, hydrophilic edible films. J Food Eng 21:395–409

Chang C, Tu S, Ghosh S, Nickerson MT (2015) Effect of pH on the inter-relationships between the physicochemical, interfacial and emulsifying properties for pea, soy, lentil and canola protein isolates. Food Res Int 77:360–367

Vogelsang-O’Dwyer M, Petersen IL, Joehnke MS, Sørensen JC, Bez J, Detzel A, Busch M, Krueger M, O’Mahony JA, Arendt EK et al (2020) Comparison of faba bean protein ingredients produced using dry fractionation and isoelectric precipitation: techno-functional, nutritional and environmental performance. Foods 9(3):322

Can Karaca A, Low N, Nickerson MT (2011) Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res Int 44(9):2742–2750

Barhoum A, García-Betancourt ML, Rahier MH, Assche GV (2018) Physicochemical characterization of nanomaterials: polymorph, composition, wettability, and thermal stability. In: Barhoum A, Makhlouf ASH (eds) Emerging applications of nanoparticles and architecture nanostructures, current prospects and future trends. Elsevier, pp 255–278

Johnston SP, Nickerson MT, Low NH (2015) The physicochemical properties of legume protein isolates and their ability to stabilize oil-in-water emulsions with and without genipin. J Food Sci Technol 52(7):4135–4145

Hu Y, Yang S, Zhang Y, Shi L, Ren Z, Hao G, Weng W (2022) Effects of microfluidization cycles on physicochemical properties of soy protein isolate-soy oil emulsion films. Food Hydrocolloids 130:107684

Floury J, Desrumaux A, Legrand J (2002) Effect of ultra-high-pressure homogenization on structure and on rheological properties of soy protein-stabilized emulsions. J Food Sci 67(9):3388–3395

McCarthy NA, Kennedy D, Hogan SA, Kelly PM, Thapa K, Murphy KM, Fenelon MA (2016) Emulsification properties of pea protein isolate using homogenization, microfluidization and ultrasonication. Food Res Int 89(Pt 1):415–421

Ningtyas DW, Bhandari B, Prakash S (2021) Modulating the fat globules of plant-based cream emulsion: Influence of the source of plant proteins. Innov Food Sci Emerg Technol 74:102852

Carpiné D, Dagostin JLA, de Andrade EF, Bertan LC, Mafra MR (2016) Effect of the natural surfactant Yucca schidigera extract on the properties of biodegradable emulsified films produced from soy protein isolate and coconut oil. Ind Crops Prod 83:364–371

Cheng J, Li Z, Wang J, Zhu Z, Yi J, Chen B, Cui L (2022) Structural characteristics of pea protein isolate (PPI) modified by high-pressure homogenization and its relation to the packaging properties of PPI edible film. Food Chem 388:132974–132974

Gul O, Saricaoglu FT, Besir A, Atalar I, Yazici F (2018) Effect of ultrasound treatment on the properties of nano-emulsion films obtained from hazelnut meal protein and clove essential oil. Ultrason Sonochem 41:466–474

Jeske S, Bez J, Arendt EK, Zannini E (2019) Formation, stability, and sensory characteristics of a lentil-based milk substitute as affected by homogenisation and pasteurisation. Eur Food Res Technol 245(7):1519–1531

Saricaoglu FT, Tural S, Gul O, Turhan S (2018) High pressure homogenization of mechanically deboned chicken meat protein suspensions to improve mechanical and barrier properties of edible films. Food Hydrocolloids 84:135–145

Galus S (2018) Functional properties of soy protein isolate edible films as affected by rapeseed oil concentration. Food Hydrocolloids 85:233–241

Xue F, Gu Y, Wang Y, Li C, Adhikari B (2019) Encapsulation of essential oil in emulsion based edible films prepared by soy protein isolate-gum acacia conjugates. Food Hydrocolloids 96:178–189

Montes-de-Oca-Ávalos JM, Altamura D, Herrera ML, Huck-Iriart C, Scattarella F, Siliqi D, Giannini C, Candal RJ (2020) Physical and structural properties of whey protein concentrate - corn oil - TiO2 nanocomposite films for edible food-packaging. Food Packag Shelf Life 26:100590

Hu Y, Shi L, Ren Z, Hao G, Chen J, Weng W (2021) Characterization of emulsion films prepared from soy protein isolate at different preheating temperatures. J Food Eng 309:110697

Galus S, Kadzińska J (2016) Moisture sensitivity, optical, mechanical and structural properties of whey protein-based edible films incorporated with rapeseed oil. Food Technol Biotechnol 54(1):78–78

Galus S, Kadzińska J (2016) Whey protein edible films modified with almond and walnut oils. Food Hydrocolloids 52:78–86

Acknowledgements

Financial support for this project was provided by the Saskatchewan Ministry of Agriculture and Development Fund.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None of the authors had any financial or non-financial conflicts of interest with this work.

Compliance with ethics requirements

This research does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, D., Stone, A.K., Sareen, J. et al. Effect of shear and legume protein-type on the mechanical and water vapour barrier properties of composite based edible films. Eur Food Res Technol (2024). https://doi.org/10.1007/s00217-024-04559-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00217-024-04559-z