Abstract

To understand the mechanism of powder transportation in a coaxial feeding system, computational fluid dynamics and the discrete element method are coupled to simulate the gas flow and metal powder transportation characteristics in a directed energy deposition feeding system. Results indicate that powder diversion occurs in the bending region of powder transportation pipes. In a conveying pipe containing powders with a particle size of 53–85 μm, powder aggregation occurs at concentrations of 5.63 and 6.26 kg/m3 in bending curvatures of 11.13 and 13.33 m−1, respectively. The ratio of the particles in the three conveying pipes transported into the mixture region is 92.8% for particles with diameters of 53–85 μm, 95.0% for particles with diameters of 85–117 μm, and 96.7% for particles with diameters of 117–150 μm. This is the reason for the smaller average size of particles in the mixture region.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Liu P, Wang Z, **ao YH, Horstemeyer MF, Cui XY, Chen L (2019) Insight into the mechanisms of columnar to equiaxed grain transition during metallic additive manufacturing. Additive Manuf 26:22–29

DebRoy T, Mukherjee T, Milewski JO, Elmer JW, Ribic B, Blecher JJ, Zhang W (2019) Scientific, technological and economic issues in metal printing and their solutions. Nat Mater 18(10):1026–1032

Busachi A, Erkoyuncu J, Colegrove P, Martina F, Watts C, Drake R (2017) A review of additive manufacturing technology and cost estimation techniques for the defence sector. CIRP J Manufact Sci Technol 19:117–128

Prasad HS, Brueckner F, Kaplan AFH (2020) Powder incorporation and spatter formation in high deposition rate blown powder directed energy deposition. Additive Manuf 35:101413

Ge P, Zhang Z, Tan ZJ, Hu CP, Zhao GZ, Guo X (2019) An integrated modeling of process-structure-property relationship in laser additive manufacturing of duplex titanium alloy. Int J Therm Sci 140:329–343

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B-Engineering 143:172–196

Koithara LL, Raoelison RN, Costil S (2020) Flow phenomenon of micron-sized particles during cold spray additive manufacturing: high-speed optic observation and characterization. Adv Powder Technol 31:1060–1079

Bayat M, Nadimpalli VK, Biondani FG, Jafarzadeh S, Thorborg J, Tiedje NS, Bissacco G, Pedersen DB, Hattel JH (2021) On the role of the powder stream on the heat and fluid flow conditions during directed energy deposition of maraging steel-multiphysics modeling and experimental validation. Additive Manuf 43:102021

Lin J (1999) Concentration mode of the powder stream in coaxial laser cladding. Opt Laser Technol 31:251–257

DebRoy T, Mukherjee T, Wei HL, Elmer JW, Milewski JO (2021) Metallurgy, mechanistic models and machine learning in metal printing. Nat Rev Mater 6(1):48–68

Liu FQ, Wei L, Shi SQ, Wei HL (2020) On the varieties of build features during multi-layer laser directed energy deposition. Additive Manuf 36:101491

Yang ZC, Wang SH, Zhu LD, Ning JS, **n B, Dun YC, Yan WT (2022) Manipulating molten pool dynamics during metal 3D printing by ultrasound. Appl Phys Reviews 9:021416

Temmler A, Pirch N, Luo J, Schleifenbaum JH, Häfner CL (2020) Numerical and experimental investigation on formation of surface structures in laser remelting for additive-manufactured Inconel 718. Surf Coat Technol 403:126370

Alya S, Singh R (2021) Discrete phase modeling of the powder flow dynamics and the catchment efficiency in laser directed energy deposition with inclined coaxial nozzles. J Manuf Sci Engineering-Transactions ASME 143(8):081004

Kim CK, Jeong JI, Choi SG, Kim JH, Cho YT (2021) High-throughput directed energy deposition process with an optimized scanning nozzle. J Mater Process Technol 295:117165

Dong G, Zhao YF (2018) Numerical and experimental investigation of the joint stiffness in lattice structures fabricated by additive manufacturing. Int J Mech Sci 148:475–485

Eisenbarth D, Esteves PMB, Wirth F, Wegener K (2019) Spatial powder flow measurement and efficiency prediction for laser direct metal deposition. Surf Coat Technol 362:397–408

Cortina M, Arrizubieta JI, Ruiz JE, Ukar E, Lamikiz (2018) A latest developments in industrial hybrid machine tools that combine additive and subtractive operations. Materials 11(12):2583

Groarke R, Danilenkoff C, Karam S, McCarthy E, Michel B, Mussatto A, Sloane J, O’Neill A, Raghavendra R, Brabazon D (2020) 316L Stainless steel powders for additive manufacturing: relationships of powder rheology, size, size distribution to Part Properties. Materials 13:5537

Zhang YC, Kong DK, Liu ST (2018) Experimental study of forced convection heat transfer of graded metal honeycomb fabricated by additive manufacturing. Int Commun Heat Mass Transfer 98:67–73

Kuang SB, Li K, Yu AB (2019) CFD-DEM simulation of large-scale dilute-phase pneumatic conveying system. Ind Eng Chem Res 59(9):4150–4160

Chen YT, Zhang XC, Parvez MM, Liou F (2020) A review on metallic alloys fabrication using elemental powder blends by laser powder directed energy deposition process. Materials 13(16):3562

Yu JH, Choi YS, Shim DS, Park SH (2018) Repairing casting part using laser assisted additive metal-layer deposition and its mechanical properties. Opt Laser Technol 106:87–93

Yang ZY, Fang H, ** KN, He JS, Ge WJ, Yan WT (2022) Physics-driven modeling of electron beam welding of Al-Cu alloys from molten pool flow, microstructure to mechanical properties. J Mater Process Technol 308:117703

Tepylo N, Huang X, Patnaik PC (2019) Laser-based additive manufacturing technologies for aerospace applications. Adv Eng Mater 21:1900617

Jackson MA, Morrow JD, Thoma DJ, Pfefferkorn FE (2020) A comparison of 316 L stainless steel parts manufactured by directed energy deposition using gas-atomized and mechanically-generated feedstock. CIRP Ann Manuf Technol 69:165–168

Sunny S, Mathews R, Gleason G, Malik A, Halley J (2021) Effect of metal additive manufacturing residual stress on post-process machining-induced stress and distortion. Int J Mech Sci 202:106534

Piscopo G, Iuliano L (2022) Current research and industrial application of laser powder directed energy deposition. Int J Adv Manuf Technol 119:6893–6917

Ke W, Bu X, Oliveira JP, Xu WG, Wang ZM, Zeng Z (2021) Modeling and numerical study of keyhole-induced porosity formation in laser beam oscillating welding of 5A06 aluminum alloy. Opt Laser Technol 133:106540

Ma YF, Evans TM, Philips N, Cunningham N (2020) Numerical simulation of the effect of fine fraction on the flowability of powders in additive manufacturing. Powder Technol 360:608–621

Odum K, Soshi M, Yamazaki K (2022) Measurement and analysis of impact dynamics suitable for modelling pneumatic transport of metallic powder flow through a directed energy deposition nozzle. Adv Powder Technol 33:103515

Tan H, Zhang C, Fan W, Zhang F, Lin X, Chen J, Huang WD (2020) Dynamic evolution of powder stream convergence with powder feeding durations in direct energy deposition. Int J Mach Tools Manuf 157:103606

Jiang S, Zheng B, Schoenung JM (2022) Directed energy deposition of metal matrix composites: computational and experimental comparison of powder particle flow behavior. J Mater Res Technology-JMR&T 16:516–529

Liu ZC, Zhang HC, Peng ST, Kim H, Du DP, Cong WL (2019) Analytical modeling and experimental validation of powder stream distribution during direct energy deposition. Additive Manuf 30:100848

Zekovic S, Dwivedi R, Kovacevic R (2007) Numerical simulation and experimental investigation of gas-powder flow from radially symmetrical nozzles in laser-based direct metal deposition. Int J Mach Tools Manuf 47:112–123

Doubenskaia M, Kulish A, Sova A, Petrovskiy P, Smurov I (2021) Experimental and numerical study of gas-powder flux in coaxial laser cladding nozzles of Precitec. Surf Coat Technol 406:126672

Iams AD, Gao MZ, Shetty A, Palmer TA (2022) Influence of particle size on powder rheology and effects on mass flow during directed energy deposition additive manufacturing. Powder Technol 396:316–326

Jeromen A, Vidergar A, Fujishima M, Levy GN, Govekar E (2022) Powder particle-wall collision-based design of the discrete axial nozzle-exit shape in direct laser deposition. J Mater Process Technol 308:117704

Guan XY, Zhao YF (2020) Numerical modeling of coaxial powder stream in laser-powder-based directed energy deposition process. Additive Manuf 34:101226

Bian YH, He XL, Yu G, Li SX, Tiana CX, Li ZY, Zhang YM, Liu JM (2022) Powder-flow behavior and process mechanism in laser directed energy deposition based on determined restitution coefficient from inverse modeling. Powder Technol 402:117355

Zhang AF, Fu W, Li DC, Lu ZL, Zhu GX, Lu QP (2011) Effect of coaxial powder nozzle design parameters and the gas flow on the powder gathering characteristics. Adv Manuf Technol 314:1935–1943

Zhu LD, Whang SH, Lu H, Qi DX, Wang D, Yang ZC, Ning JS, Dun YC, Xue PS, Xu PH (2020) Investigation on synergism between additive and subtractive manufacturing for curved thin-walled structure. Virtual Phys Prototyp 17(2):220–238

Liu H, Hao JB, Yu G, Yang HF, Wang LW, Han ZT (2016) A numerical study on metallic powder flow in coaxial laser cladding. J Appl Fluid Mech 9(5):2247–2256

Zou BK, Wang L, Zhang YM, Liu Y, Ouyang QB, ** SB, Zhang D, Yan WT, Li Z (2023) Enhanced strength and ductility of metal composites with intragranularly dispersed reinforcements by additive manufacturing. Mater Res Lett 11(5):360–366

Vallabh CKP, Cetinkaya C (2021) Single particle adhesion variability in additive manufacturing powders. J Adhes 97:19–37

Zhang DY, Qiu D, Gibson MA, Zheng YF, Fraser HL, StJohn DH, Easton MA (2019) Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 576:91–95

Jeon TJ, Hwang TW, Yun HJ, VanTyne CJ, Moon YH (2018) Control of porosity in parts produced by a direct laser melting process. Appl Sciences-Basel 8(12):2573–2588

Peng KY, Huang HH, Xu HM, Kong Y, Zhu LB, Liu ZF (2023) A molecular dynamics study of laser melting of densely packed stainless steel powders. Int J Mech Sci 243:108034

Gong JQ, Wei KW, Liu MN, Song WJ, Li XY, Zeng XY (2022) Microstructure and mechanical properties of AlSi10Mg alloy built by laser powder bed fusion/direct energy deposition hybrid laser additive manufacturing. Additive Manuf 59:103160

Wang L, Zhang YM, Yi CH, Yan WT (2022) Mechanism of keyhole pore formation in metal additive manufacturing. Npj Comput Mater 7:143–153

Dill J, Soshi M, Yamazaki K (2020) A study on the effect of directed energy deposition substrate energy on clad geometry. Int J Adv Manuf Technol 109:315–333

Zhao Y, Chew JW (2021) Effect of lognormal particle size distributions on particle spreading in additive manufacturing. Adv Powder Technol 32(4):1127–1144

Pan H, Sparks T, Thakar YD, Liou F (2006) The investigation of gravity-driven metal powder flow in coaxial nozzle for laser-aided direct metal deposition process. J Manuf Sci Engineering-Transactions ASME 128(2):541–553

Ferreira E, Dal M, Colin C, Marion G, Gorny C, Courapied D, Guy J, Peyre P (2020) Experimental and numerical analysis of gas/powder flow for different LMD nozzles. Metals 10(5):667

Aggarwal A, Patel S, Vinod AR, Kumar A (2021) An integrated Eulerian-Lagrangian-Eulerian investigation of coaxial gas-powder flow and intensified particle-melt interaction in directed energy deposition process. Int J Therm Sci 166:106963

Balu P, Leggett P, Kovacevic R (2012) Parametric study on a coaxial multi-material powder flow in laser-based powder deposition process. J Mater Process Technol 212(7):1598–1610

Kovaleva I, Kovalev O, Zaitsev A, Smurov I (2013) Numerical simulation and comparison of powder jet profiles for different types of coaxial nozzles in direct material deposition. Lasers Manuf 41:870–872

Dao MH, Lou J (2021) Simulations of laser assisted additive manufacturing by smoothed particle hydrodynamics. Comput Methods Appl Mech Eng 373:113491

Zhang XY, Li DC, Zhu WJ (2020) Numerical modeling design for the hybrid additive manufacturing of laser directed energy deposition and shot peening forming Fe-Cr-Ni-B-Si alloy. Materials 13(21):4877

Tsuji Y, Kawaguchi T, Tanaka T (1993) Discrete particle simulation of 2-dimensional fluidized-bed. Powder Technol 77(1):79–87

Haley JC, Schoenung JM, Lavernia EJ (2019) Modelling particle impact on the melt pool and wettability effects in laser directed energy deposition additive manufacturing. Mater Sci Eng A-Structural Mater Prop Microstruct Process 761:138052

Chen H, Wei QS, Zhang YJ, Chen F, Shi YS, Yan WT (2019) Powder-spreading mechanisms in powder-bed-based additive manufacturing: experiments and computational modeling. Acta Mater 179:158–171

Haider A, Levenspiel O (1989) Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol 58(1):63–70

Cundall PA, Strack ODL (1980) A discrete numerical model for granular assemblies-reply. Geotechnique 30(3):335–336

Vundru C, Singh R, Yan WY, Karagadde S (2021) Effect of spreading of the melt pool on the deposition characteristics in laser directed energy deposition. Procedia Manuf 53:407–416

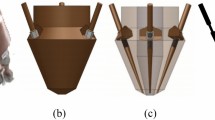

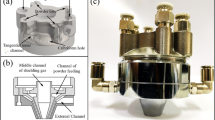

Gao GC, Zhang XW, Han YB, Xu M, Liu H, Ao JX, Cai YZ, Wang JZ, Wang MZ (2023) Structural design of a coaxial-jet vortex powder mixer for multi-material directed energy deposition. Powder Technol 425:118586

Garg R, Dhami HS, Panda PR, Viswanathan K (2023) Evaluating gas-driven flow mechanics of non-spherical powders for directed energy deposition. J Manuf Process 99:260–271

Mansour A, Laurien E (2018) Numerical error analysis for three-dimensional CFD simulations in the two-room model containment THAI+: grid convergence index, wall treatment error and scalability tests. Nucl Eng Des 326:220–233

Longest PW, Vinchurkar S (2007) Effects of mesh style and grid convergence on particle deposition in bifurcating airway models with comparisons to experimental data. Med Eng Phys 29:350–366

Daniels SJ, Rahat AAM, Tabor GR, Fieldsend JE, Everson RM (2020) Shape optimisation of the sharp-heeled Kaplan draft tube: performance evaluation using computational fluid dynamics. Renewable Energy 160:112–126

Roache PJ (1997) Quantification of uncertainty in computational fluid dynamics. Annu Rev Fluid Mech 29:123–160

Lei H, Zhu LT, Luo ZH (2023) Study of fluid cell coarsening for CFD-DEM simulations of polydisperse gas-solid flows. Particuology 73:128–138

Yao XX, Li JY, Wang YF, Gao X, Li T, Zhang Z (2021) Experimental and numerical studies of nozzle effect on powder flow behaviors in directed energy deposition additive manufacturing. Int J Mech Sci 210:106740

Gao X, Yao XX, Niu FY, Zhang Z (2022) The influence of nozzle geometry on powder flow behaviors in directed energy deposition additive manufacturing. Adv Powder Technol 33:103487

Zhao P, Xu J, Zhao BD, Wang J (2022) Cartesian grid simulation of reacting gas-solid flow using CFD-DEM-IBM method. Powder Technol 407:117651

Takemura S, Koike R, Kakinuma Y, Sato Y, Oda Y (2019) Design of powder nozzle for high resource efficiency in directed energy deposition based on computational fluid dynamics simulation. Int J Adv Manuf Technol 105:4107–4121

Li G, Odum K, Yau C, Soshi M, Yamazaki K (2021) High productivity fluence based control of directed energy deposition (DED) part geometry. J Manuf Process 65:407–417

Kumaran M, Senthilkumar V (2021) Generative design and topology optimization of analysis and repair work of industrial robot arm manufactured using additive manufacturing technology. IOP Conference Series Materials Science and Engineering 1012

Funding

This work was supported by the National Natural Science Foundation of China (12372191, 52332012) and the National Key Research and Development Program of China (2022YFB4600902) to Zhao Zhang.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Lichao Zhang, **ang Gao and Zhao Zhang. The first draft of the manuscript was written by Lichao Zhang and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Gao, X. & Zhang, Z. Simulation of powder transportation in directed energy deposition. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13851-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13851-x