Abstract

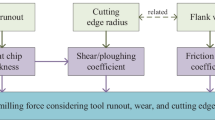

Accurate theoretical analysis and modeling of instantaneous uncut chip thickness (IUCT) play a crucial role in the cutting force prediction of the micro-milling process. Tool wear and tool runout have a significant influence on the IUCT and become key factors to be considered. An IUCT model covering the influence of tool runout and tool flank wear considering tool edge radius is proposed. Based on this the prediction model of the cutting force is constructed in the micro-end milling process. Firstly, an actual tool radius model considering tool flank wear and tool edge radius is analyzed. The IUCT model is established by constructing the trochoidal trajectories of the current cutting edge and all cutting edges in the previous cycle considering tool flank wear and tool runout. Moreover, tool flank wear and tool runout are considered in the determination of cutter-workpiece engagement and the calibration of cutting force coefficients. Effectiveness of the established cutting force model is verified by micro milling experiments and statistical analysis. Results show that tool flank wear has a significant effect on the cutting forces of the three directions, and the influence of tool flank wear on the IUCT is small in a certain range. This work for predicting the IUCT and cutting force sheds new light on revealing various derived physical phenomena such as deformation, heat, and stress in the micro-cutting process.

Highlights

The instantaneous uncut chip thickness model covering the influence of tool runout and tool flank wear considering tool edge radius is proposed.

The micro-milling cutting force based on instantaneous uncut chip thickness is predicted from the mechanism level.

Effectiveness of the established cutting force model is verified by micro-milling experiments and statistic analysis.

The influence of tool flank wear on the instantaneous uncut chip thickness and cutting force is analyzed.

Similar content being viewed by others

Data availability

The measuring data in our paper are available from the corresponding author by request, and other related materials can also be obtained from the corresponding author.

Code availability

The code for cutting force model during the study is available from the corresponding author by request.

References

Anand RS, Patra K (2014) Modeling and simulation of mechanical micro-machining-a review. Mach Sci Technol 18(3):323–347

Davim JP (2014) Modern mechanical engineering: Research, development and education. Springer Science & Business Media, London

Balázs BZ, Geier N, Takács M, Davim JP (2021) A review on micro-milling: recent advances and future trends. Int J Adv Manuf Technol 112(3):655–684

Chen N, Li HN, Wu J, Wu JM, Li ZJ, Li L, Liu GY, He N (2020) Advances in micro-milling: from tool fabrication to process outcomes. Int J Mach Tools Manuf 160:103670

Altintas Y (2000) Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design. Cambridge University Press, UK

Bao WY, Tansel IN (2000) Modeling micro-end milling operations. Part I: analytic cutting force model. Int J Mach Tools Manuf 40(15):2155–2173

Zhang XW, Yu TB, Dai YX, Qu S, Zhao J (2020) Energy consumption considering tool wear and optimization of cutting parameters in micro-milling process. Int J Mech Sci 178:105628

Zhu KP, Li G (2021) Theoretical modeling and experimental study of micro-milling force based on tool wear map**. J Mech Eng 19:246–259

Bao WY, Tansel IN (2000) Modeling micro-end milling operations. Part II: tool runout. Int J Mach Tools Manuf 40(15):2175–2192

Vogler MP, DeVor RE, Kapoor SG (2005) On the modeling and analysis of machining performance in Micro-End milling, Part II: Cutting Force Prediction. J Manuf Sci Eng 126:695–705

Rodríguez P, Labarga JE (2013) A new model for the prediction of cutting forces in micro-end-milling operations. J Mater Process Tech 213(2):261–268

Zhang XW, Ehmann KF, Yu TB, Wang WS (2016) Cutting forces in micro-end milling processes. Int J Mach Tools Manuf 107:21–40

Li K, Zhu K, Mei T (2016) A generic instantaneous undeformed chip thickness model for the cutting force modeling in micromilling. Int J Mach Tool Manuf 105:23–31

Moges TM, Desai KA, Rao PVM (2018) Modeling of cutting force, tool deflection, and surface error in micro-milling operation. Int J Adv Manuf Technol 98:2865–2881

Wojciechowski S, Matuszak M, Powałka B, Madajewski M, Maruda RW, Krolczyk GM (2019) Prediction of cutting forces during micro end milling considering chip thickness accumulation. Int J Mach Tools Manuf 147:103466

Wan M, Wen DY, Ma YC, Zhang WH (2019) On material separation and cutting force prediction in micro-milling through involving the effect of dead metal zone. Int J Mach Tools Manuf 146:103452

Moges TM, Desai KA, Rao PVM (2016) Improved process geometry model with cutter runout and elastic recovery in micro-end milling. Procedia Manuf 5:478–494

Yuan YJ, **g XB, Ehmann KF, Cao J, Li HZ, Zhang DW (2018) Modeling of cutting forces in micro end-milling. J Manuf Process 31:844–858

**g XB, Lv R, Chen Y, Tian Y, Li H (2020) Modelling and experimental analysis of the effects of runout, minimum chip thickness and elastic recovery on the cutting force in micro-end milling. Int J Mech Sci 176:105540

**g XB, Lv R, Song B, Xu J, Jaffery S (2021) A novel run-out model based on spatial tool position for micro-milling force prediction. J Manuf Process 68:739–749

Wan M, Wen DY, Zhang WH, Yang Y (2023) Prediction of cutting forces in flexible micro milling processes by considering the change of instantaneous cutting direction. J Manuf Process 90:180–195

Bao WY, Tansel IN (2000) Modeling micro-end milling operations. Part III: influence of tool wear. Int J Mach Tools Manuf 40(15):2193–2211

Li G, Li S, Zhu K (2020) Micro-milling force modeling with tool wear and runout effect by spatial analytic geometry. Int J Adv Manuf Technol 107(9):631–343

Liu T, Liu Y, Zhang K (2022) An improved cutting force model in micro-milling considering the comprehensive effect of tool runout, size effect and tool wear. Int J Adv Manuf Technol 120:659–668

Gao S, Duan X, Zhu K, Zhang Y (1805) Generic cutting force modeling with comprehensively considering tool edge radius, tool flank wear and tool runout in micro-end milling. Micromachines 2022:13

Funding

This research was supported by the National Natural Science Foundation of China (No. 51605346). Key research and development program of Hubei Province (2022BAA059).

Author information

Authors and Affiliations

Contributions

**anyin Duan, Kunpeng Zhu, and Shuaishuai Gao proposed the method of the paper. Kunpeng Zhu and Yu Zhang provided the experimental settings and data. Shuaishuai Gao and **anyin Duan wrote the first draft of the article and completed the programming prediction and experimental data analysis. Shuaishuai Gao completed the modification and polish of the whole manuscript and drawing of all the figures and tables. **anyin Duan, Kunpeng Zhu and Yu Zhang made many constructive suggestions for the modeling, experiments and the writing of the whole paper. All authors have read and agreed to the published.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors and facilitators have certified their participation in this work.

Consent for publication

All authors certify that they consent to publish the article. The article is the author’s original work and has not been published in advance or considered for publication elsewhere.

Conflicts of interest

The authors have no relevant financial or non-financial interests to disclose. The authors have no conflicts of interest to declare that are relevant to the content of this article. All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Prime novelty statement

This manuscript titled of Influence of tool flank wear with considering tool edge radius on instantaneous uncut chip thickness and cutting force in micro-end milling is original, it is not submitted to else journals simultaneously, and all authors agree to submit it to The International Journal of Advanced Manufacturing Technology. Moreover, this is a preliminary, novel research paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, S., Duan, X., Zhu, K. et al. Influence of tool flank wear considering tool edge radius on instantaneous uncut chip thickness and cutting force in micro-end milling. Int J Adv Manuf Technol 133, 1639–1650 (2024). https://doi.org/10.1007/s00170-024-13794-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13794-3