Abstract

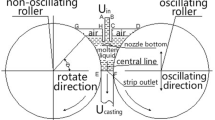

A three-demensional numerical model is established to predict the free surface, the temperature field, the flow field, the turbulent kinectic energy, the outlet temperature, and the liquid fraction in the twin roll strip casting and rolling molten pool with side dams vibrating. The numerical simulations are also conducted to compare the flow and heat transfer characteristics under different vibration frequencies and different casting temperatures. The results show that the heat transfer is enhanced, the mixing of solutes is optimized, the strip outlet temperatures are homogeniazed, the kiss lines are higher, and the rolling intervals are extended as the frequency increased. Excessive casting temperature leads some unexpected problems such as liquid steel leakage and unformed strips. It also makes the height of kiss line uneven. Lower casting temperature leads the strip outlet temperature more uniform. It also leads the kiss lines higher. Finally, a new approach to advancing the development of twin roll strip casting and rolling is proposed through these analyses.

Similar content being viewed by others

References

Wang B, Zhang JY, Li XM, Wei HQ (2010) Simulation of solidification microstructure in twin-roll casting strip. Comput Mater Sci 49:135–139

Raabe D, Degenhardt R, Seliger R, Klos W, Sachtleber M, Ernenputsch L (2008) Advances in the optimization of thin strip cast austenitic 304 stainless steel. Steel Res Int 79:440–444

Haga T, Nishida S, Watari H (2017) Semisolid strip casting of aluminum alloy by a twin roll caster equipped with a channel scraper. Key Eng Mater 748:181–186

Haga T, Suzuki S (2001) A high speed twin roll caster for aluminum alloy strip. J Mater Process Technol 113:291–295

Cao G, Zhang S, Chen J, Jia F, Fang F, Li C (2021) Microstructure and precipitate evolution in Cu-3.2Ni-0.75Si alloy processed by twin-roll strip casting. J Mater Eng Perform 30:1318–1329

Zhou Z, Wang Z, Yu Y, Jiang S, Wang G, Cheng J (2012) Novel side dams including advanced laminated ceramic for twin roller continuous casting. Ceram Int 38:1779–1783

Chang F, Hull J, Wang Y, Blazek K (2005) Computer modeling of electromagnetic fields and fluid flows for edge containment in continuous casting. J Manuf Sci Eng 127:724–730

Bao P, Di H, Qian A, Zhang X (2003) 3-D Numerical simulation of the electromagnetic dam of twin roll casting using edge element method. J Mater Sci Technol 19:116–119

Yang J, Yuan Z, Yu X, Li H, Shi H, Peng Q (2018) Research status of material and technology of side sealing plate for thin strip continuous casting. China Metall 28:1–6

Fournier P, Platon F (2000) Wear of refractory ceramics against nickel. Wear 244:118–125

Liang X, Pan F, Zhou S, Ding P, Xu X (1997) Edge containment of a twin-roll caster for near net shape strip casting. J Mater Process Technol 63:788–791

Sun M, Zheng C, Du F, Zhu Z (2020) A novel design of electromagnetic side sealing in twin-roll strip cast-rolling process. Mech Based Des Struc 49:1010–1027

McBrien M, Allwood J (2013) Preliminary design and assessment of a novel electromagnetic edge dam for aluminium twin roll casting. Mater Sci Forum 765:87–91

Mcbrien M, Allwood J, Barekar N (2015) Tailor blank casting - control of sheet width using an electromagnetic edge dam in aluminium twin roll casting. J Mater Process Technol 224:60–72

Schneider W, Lossack E (2013) Improvement of billet quality by use of a hot top mold with a two phase lubrication. Essen Read Light Metals 3:571–576

Eskin G, Eskin D (1997) Ultrasonic treatment of light alloy melts. Boca Raton

Omura N, Murakami Y, Li MJ, Tamura T, Miwa K, Furukawa H, Harada M (2009) Effects of mechanical vibration on cooling rate and DAS of AC4C aluminum alloy gravity die castings. Mater Trans 50:2604–2608

Jian X, Meek T, Han Q (2006) Refinement of eutectic silicon phase of aluminum A356 alloy using high-intensity ultrasonic vibration. Scr Mater 54:893–896

Miwa K, Tamura T, Li M, Omura N (2011) Effect of vibration during solidification to obtain high potential metallic materials. Mater Sci Forum 690:162–165

Jian X, Xu H, Meek T (2005) Effect of power ultrasound on solidification of aluminum A356 alloy. Mater Lett 59:190–193

Wang X, Guan R, Guo N, Zhao Z, Zhang Y, Su N (2016) Metal solidification–nucleation–rate model under coupling effects of shearing flow and vibration. Mater Sci Technol 32:154–163

Wang X, Guan R (2018) Heat transfer and cooling rate model of flow melt on vibration wall. Trans Indian Inst Met 71:1635–1641

Kudryashova O, Khmeleva M, Danilov P, Dammer V, Vorozhtsov A, Eskin D (2019) Optimizing the conditions of metal solidification with vibration. Metals 9:366–379

Yao L, Hao H, Ji S, Fang C, Zhang X (2011) Effects of ultrasonic vibration on solidification structure and properties of Mg-8Li-3Al alloy. Trans Nonferrous Met Soc China 21:1241–1246

Lyubimov D, Lyubimova T, Tcherepanov A, Roux B, Billia B, Nguyen-Thi H (2005) Vibration influence on morphological instability of a solidification front. Microgravity Sci Technol 16:290–294

Niu S, Senk D, Rezende J (2019) Numerical modeling of the effect of mechanical vibration on 10kg C45 seel ingot solidification. Steel Res Int 90:190081–190089

Dai G, Wu S, Chen W, Huang X (2020) Mechanism of P-wave promoting the solidification feeding in the low-pressure casting of ZL205A alloy. Int J Cast Met Res 33:177–183

Zang X, Wang X, Ma Y, Yao M, Zhang L, Ye S (2008) The shell surface force caused by mould friction during slab continuous casting. ISIJ Int 48:170–174

Lankford W (1972) Some considerations of strength and ductility in the continuous-casting process. Metall Trans 3:1331–1357

Schwerdtfeger K, Sha H (2000) Depth of oscillation marks forming in continuous casting of steel. Metall Mater Trans B 31:813–826

Zang X, Liu L, Yang Q (2021) Cracking possibility evaluation of 304 stainless steel during twin roll casting by 3D simulation. J Mater Eng Perform 30:2014–2020

Miyazawa K, Szekely J (1981) A mathematical model of the splat cooling process using the twin-roll technique. Metall Trans A 12:1047–1057

Santos C, Spim J, Garcia A (2000) Modeling of solidification in twin-roll strip casting. J Maters Process Technol 102:33–39

Hwang J, Lin H, Hwang W, Hu C (1995) Numerical simulation of metal flow and heat transfer during twin roll strip casting. ISIJ Int 35:170–177

Xu M, Li Z, Wang Z, Zhu M (2016) Computational and experimental study of the transient transport phenomena in a full-scale twin-roll continuous casting machine. Metall Mater Trans B 48:1–17

Pelss A, Rückert A, Pfeifer H (2016) Numerical investigations of influences on the flow in a vertical twin roll strip caster for stainless steel. Metall Ita 2:31–36

Jiang C, Rui Y (2017) Thermodynamic behavior research analysis of twin-roll casting lead alloy strip process. Chin J Mech Eng 30:352–362

Bouchard D, Hamel G, Turcotte S, Nadeau J (2001) Water modeling evaluation of metal delivery in a twin roll strip caster using pool level and residence time distribution measurements. ISIJ Int 41:1465–1472

Meter F (1993) Zonal two equation kappa-omega turbulence models for aerodynamic flows. AIAA 93–2906. https://doi.org/10.2514/6.1993-2906

Kim S, Chung B, Kim M (2002) Numerical analysis on melting and solidification of pure metals with enthalpy-porosity model. J Energ Eng 11:99–105

Hirt C, Nichols B (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39:201–225

Fang Y, Wang Z, Yang Q, Zhang Y, Liu L, Hu H, Zhang Y (2009) Numerical simulation of the temperature fields of stainless steel with different roller parameters during twin-roll strip casting. Int J Miner Metall Mater 16:304–308

Du F, Wang X, Wang Y, Sun M, Xue S, Zheng L (2017) Interfacial heat transfer model of twin-roll strip casting molten pool based on kiss point position. Foundry Technol 38:132–137

Nie D, Liu X (2014) Transient simulation and analysis of wave-surface in molten pool of double-roller continuous casting strip. Spec Cast Nonferrous Alloys 34:777–780

Fujita Y, Sato H, Kitagawa T, Nishioka S, Tsuchida Y, Ozeki A (1989) Solidification and roll-bonding of shells in twin-roll casting process. ISIJ Int 29:495–502

Reza M, Hasan M, Guthrie R (1995) Coupled turbulent flow, heat, and solute transport in continuous casting processes. Metall Mater Trans B 26:731–744

Zhang X, Jiang Z, Liu X, Wang G (2006) Simulation of fluid flow, heat transfer and micro-segregation in twin-roll strip casting of stainless steel. J Mater Sci Technol 3:295–300

Sun M, Yang Y, Zhu Z, Wei J, Du F (2019) Experimental study on twin-roller strip cast-rolling under vibration of 20CrMn steel. J Mech Eng, Chin Ed 55:54–59

Wei J, Xu Z, Sun M, Zhu Z, Wang H, Du F (2018) Experimental research of vibratory cast-rolling strips for 20CrMn alloy steel. Iron Steel (Bei**g, China) 53:118–121

Du F, Lv Z, Huang H, Xu Z, An Z (2015) Mechanism and experiment research on centerline segregation of twin-roll strip casting. Trans Nonferrous Met Soc China 25:2738–2744

Funding

This work was supported by the National Natural Science Foundation of China (No. 51706037).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, C., Xue, Y., Yan, F. et al. Numerical simulation on flow and heat transfer in twin roll strip casting and rolling molten pool with side dams vibrating. Int J Adv Manuf Technol 125, 4497–4512 (2023). https://doi.org/10.1007/s00170-023-10930-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-10930-3