Abstract

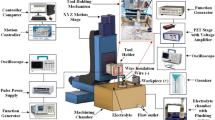

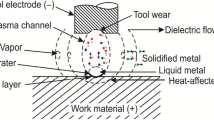

Nickel-titanium alloy (Nitinol) is an excellent shape memory alloy (SMA) for microelectro-mechanical systems (MEMS) particularly in biomedical applications owing to its three excellent features shape memory effect (SME), superelasticity, and biocompatibility. The temperature-dependent material transformation properties of Nitinol SMAs make conventional machining difficult. Micro-ECM, a non-conventional machining process for conductive materials regardless of their strength and hardness, has the potential to fabricate microfeatures on Nitinol. This study presents the investigation on the electrochemical dissolution behavior of Nitinol in different electrolytes for micro-ECM. The influence of electrolytes on the nature of dissolution of Nitinol was studied by fabricating microchannels in three levels of parameters containing applied voltage and electrolyte concentration. The first three electrolytes were all aqueous neutral electrolytes, i.e., NaCl, NaNO3, and NaBr. The aqueous NaNO3 was successful in fabricating microchannels at all levels of process parameters. However, aqueous electrolytes form relatively a huge amount of sludge on the machined surface reducing both dissolution efficiency and machining accuracy. Thus, ethylene glycol-based NaNO3 was used to fabricate microchannels with lower depth overcut (DOC), width overcut (WOC), and length overcut (LOC) with respect to aqueous NaNO3 electrolyte. The potentiodynamic polarization (PDP) tests of Nitinol through cyclic voltammetry (CV) shows passive dissolution in aqueous electrolyte and active dissolution in non-aqueous electrolyte.

Similar content being viewed by others

References

Wang FE, Buehler WJ, Pickart SJ (1965) Crystal structure and a unique “martensitic” transition of TiNi. J Appl Phys 36:3232–3239. https://doi.org/10.1063/1.1702955

Kauffman GB, Mayo I (1997) The story of nitinol: the serendipitous discovery of the memory metal and its applications. Chem Educ 2:1–21. https://doi.org/10.1007/s00897970111a

Otsuka K, Ren X (2005) Physical metallurgy of Ti-Ni-based shape memory alloys. Prog Mater Sci 50:511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

Santoro M, Nicolay OF, Cangialosi TJ (2001) Pseudoelasticity and thermoelasticity of nickel-titanium alloys: a clinically oriented review. Part I: Temperature transitional ranges. Am J Orthod Dentofac Orthop 119:587–593. https://doi.org/10.1067/mod.2001.112446

Patel SK, Behera B, Swain B et al (2020) A review on NiTi alloys for biomedical applications and their biocompatibility. Mater Today Proc 33:5548–5551. https://doi.org/10.1016/j.matpr.2020.03.538

Kahn H, Huff MA, Heuer AH (1998) The TiNi shape-memory alloy and its applications for MEMS. J Micromech Microeng 8:213–221. https://doi.org/10.1088/0960-1317/8/3/007

Mahalik NP (2008) MEMS. Tata McGraw-Hill Publishing Company Limited, New Delhi

Fujita H (1998) Microactuators and micromachines Proc IEEE 86:1721–1732. https://doi.org/10.1109/5.704278

Fu Y, Du H, Huang W et al (2004) TiNi-based thin films in MEMS applications: a review. Sens Actuators A Phys 112:395–408. https://doi.org/10.1016/j.sna.2004.02.019

Mwangi JW, Nguyen LT, Bui VD et al (2019) Nitinol manufacturing and micromachining: a review of processes and their suitability in processing medical-grade nitinol. J Manuf Process 38:355–369. https://doi.org/10.1016/j.jmapro.2019.01.003

Kowalczyk M (2017) Application of Taguchi method to optimization of surface roughness during precise turning of NiTi shape memory alloy. Photonics Appl Astron Commun Ind High Energy Phys Exp 2017(10445):104455G. https://doi.org/10.1117/12.2281062

Kuppuswamy R, Yui A (2017) High-speed micromachining characteristics for the NiTi shape memory alloys. Int J Adv Manuf Technol 93:11–21. https://doi.org/10.1007/s00170-015-7598-9

Wells SL (2013) Microdrilling of nitinol. Texas A&M University

Huang H, Zhang H, Zhou L, Zheng HY (2003) Ultrasonic vibration assisted electro-discharge machining of microholes in Nitinol. J Micromech Microeng 13:693–700. https://doi.org/10.1088/0960-1317/13/5/322

Unune DR, Nirala CK, Mali HS (2019) Accuracy and quality of micro-holes in vibration assisted micro-electro-discharge drilling of Inconel 718. Meas J Int Meas Confed 135:424–437. https://doi.org/10.1016/j.measurement.2018.11.067

James S, Mahajan A (2018) Experimental study of machining of smart materials using submerged abrasive waterjet micromachining process. ASME Int Manuf Sci Eng Conf MSEC 4:1–8. https://doi.org/10.1115/MSEC2018-6494

Katona B, Bognár E, Berta B et al (2013) Chemical etching of nitinol stents. Acta Bioeng Biomech 15:3–8. https://doi.org/10.5277/abb130401

Lee ES, Shin TH, Kim BK et al (2007) Electrochemical micromachining of nitinol by confined-etchant-layer technique. Int J Mach Tools Manuf 127:28–56. https://doi.org/10.1016/j.ijmachtools.2018.01.004

Lee ES, Shin TH, Kim BK, Baek SY (2010) Investigation of short pulse electrochemical machining for groove process on Ni-Ti shape memory alloy. Int J Precis Eng Manuf 11:113–118. https://doi.org/10.1007/s12541-010-0014-3

Saxena KK, Qian J, Reynaerts D (2018) A review on process capabilities of electrochemical micromachining and its hybrid variants. Int J Mach Tools Manuf 127:28–56. https://doi.org/10.1016/j.ijmachtools.2018.01.004

Mingcheng G, Yongbin Z, Lingchao M (2019) Electrochemical micromachining of square holes in stainless steel in H2SO4. Int J Electrochem Sci 14:414–426. https://doi.org/10.20964/2019.01.40

Anasane SS, Bhattacharyya B (2016) Experimental investigation on suitability of electrolytes for electrochemical micromachining of titanium. Int J Adv Manuf Technol 86:2147–2160. https://doi.org/10.1007/s00170-015-8309-2

Pooranachandran K, Deepak J, Hariharan P, Mouliprasanth B (2019) Effect of flushing on electrochemical micromachining of copper and Inconel 718 alloy. In: Vijay Sekar KS, Gupta M, Arockiarajan A (eds) Advances in Manufacturing Processes. Springer Singapore, Singapore, pp 61–69

Sethi A, Acharya BR, Saha P (2019) Fabrication of high aspect ratio cylindrical tungsten micro tool by reverse micro-ECM process. Int J Precis Technol 8:201. https://doi.org/10.1504/ijptech.2019.10022607

Sethi A, Acharya BR, Saha P (2022) Electrochemical dissolution of WC-Co micro-tool in Micro-WECM using an eco-friendly citric acid mixed NaNO 3 electrolyte. J Electrochem Soc 169:033503. https://doi.org/10.1149/1945-7111/ac54d9

Mineta T (2004) Electrochemical etching of a shape memory alloy using new electrolyte solutions. J Micromech Microeng 14:76–80. https://doi.org/10.1088/0960-1317/14/1/310

Ma XZ, Zhang L, Cao GH et al (2007) Electrochemical micromachining of nitinol by confined-etchant-layer technique. Electrochim Acta 52:4191–4196. https://doi.org/10.1016/j.electacta.2006.11.046

Maurer JJ, Hudson JL, Fick SE et al (2012) Electrochemical micromachining of NiTi shape memory alloys with ultrashort voltage pulses. Electrochem Solid-State Lett 15:28–30. https://doi.org/10.1149/2.002202esl

Ao S, Li K, Liu W et al (2020) Electrochemical micromachining of NiTi shape memory alloy with ethylene glycol–NaCl electrolyte containing ethanol. J Manuf Process 53:223–228. https://doi.org/10.1016/j.jmapro.2020.02.019

Mouliprasanth B, Hariharan P (2021) Influence of variant electrolyte in electrochemical micromachining of micro holes in SMA using Taguchi optimization. Russ J Electrochem 57:197–213. https://doi.org/10.1134/S1023193521030095

Ding R, Shang JX, Wang FH, Chen Y (2018) Electrochemical Pourbaix diagrams of Ni–Ti alloys from first-principles calculations and experimental aqueous states. Comput Mater Sci 143:431–438. https://doi.org/10.1016/j.commatsci.2017.11.033

Asserghine A, Medvidović-Kosanović M, Nagy L, Nagy G (2019) In situ monitoring of the transpassivation and repassivation of the passive film on nitinol biomaterial by scanning electrochemical microscopy. Electrochem Commun 107:106539. https://doi.org/10.1016/j.elecom.2019.106539

Wang Y, Wei X, Li Z et al (2020) Electrolytic polishing of nitinol based cardiovascular stent in NaCl-ethylene glycol-ethanol-water electrolyte. Int J Electrochem Sci 15:8823–8836. https://doi.org/10.20964/2020.09.01

Davydov AD, Kabanova TB, Volgin VM (2017) Electrochemical machining of titanium. Review Russ J Electrochem 53:941–965. https://doi.org/10.1134/S102319351709004X

Zarubitskii OG, Dmitruk BF, Zakharchenko NF (2007) Titanium interaction with hydroxide-salt melts. Prot Met 43:483–486. https://doi.org/10.1134/S0033173207050116

Muñoz-Portero MJ, García-Antón J, Guiñón JL, Pérez-Herranz JL (2007) Pourbaix diagrams for nickel in concentrated aqueous lithium bromide solutions at 25 °C. Corrosion 63:625–634. https://doi.org/10.5006/1.3278412

Liu W, Zhang H, Luo Z et al (2018) Electrochemical micromachining on titanium using the NaCl-containing ethylene glycol electrolyte. J Mater Process Technol 255:784–794. https://doi.org/10.1016/j.jmatprotec.2018.01.009

Yusen H, Tao Y, Zhengyang X, Yongbin Z (2021) Electrochemical micromachining of ZrCu-based amorphous alloy in ethylene glycol solution. Intermetallics 132:107155. https://doi.org/10.1016/j.intermet.2021.107155

Wang J, Torres-Sanchez C, Borgman JM et al (2020) Template-free, microscale dimple patterning of pure titanium surface through anodic dissolution using non-aqueous ethylene glycol-TiCl4 electrolytes. Surf Coatings Technol 404:126555. https://doi.org/10.1016/j.surfcoat.2020.126555

Hryniewicz T (1994) Concept of microsmoothing in the electropolishing process. Surf Coatings Technol 64:75–80. https://doi.org/10.1016/S0257-8972(09)90006-8

Lee ES, Shin TH (2011) An evaluation of the machinability of nitinol shape memory alloy by electrochemical polishing. J Mech Sci Technol 25:963–969. https://doi.org/10.1007/s12206-011-0209-2

Elgrishi N, Rountree KJ, McCarthy BD et al (2018) A practical beginner’s guide to cyclic voltammetry. J Chem Educ 95:197–206. https://doi.org/10.1021/acs.jchemed.7b00361

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Mr. Abhijeet Sethi, Mr. Biswesh Ranjan Acharaya, and Dr. Partha Saha. The first draft of the manuscript was written by Mr. Abhijeet Sethi, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sethi, A., Acharya, B.R. & Saha, P. Study of the electrochemical dissolution behavior of Nitinol shape memory alloy in different electrolytes for micro-ECM process. Int J Adv Manuf Technol 121, 7019–7035 (2022). https://doi.org/10.1007/s00170-022-09802-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09802-z