Abstract

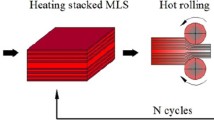

Thick steel/aluminum/aluminum-alloy composite plates are one of the key materials connecting steel structures and aluminum alloy structures and have been widely used in the shipbuilding industry and other fields. However, steel/aluminum/aluminum-alloy composite plates with a total thickness of more than 10 mm and a steel layer thickness of more than 5 mm are prone to problems such as inconsistent deformation of component metals and low bonding strength during the rolling process, and cannot be continuously prepared. To solve this problem, this article proposes a two-pass different temperature rolling process for thick steel/aluminum/aluminum-alloy composite plates and conducts research on Q235B steel, 1060 aluminum, and 5083 aluminum alloy as component metals. The results show that the process is reliable. It can prepare Q235B/1060/5083 composite plates with a thickness of 15.65 mm without oxygen protection measures. Meanwhile, the interfacial shear and pull-off strength of the composite plates obtained under different experimental conditions in this article are higher than the requirements of the US military standards MIL-J-24445A and Chinese ship standard CB20091-2012. The composite plates show good performance in 90° and 137° bending tests without obvious defects. Under the best condition, a 1.48 μm interlocking diffusion layer is formed at the steel/aluminum interface of the composite plates, the interfacial shear strength exceeds 70 MPa, and the interfacial pull-off strength exceeds 110 MPa. Finally, according to the experimental results, the reasons for the feasibility of the two-pass different temperature rolling of thick steel/aluminum/aluminum-alloy composite plates are given.

Similar content being viewed by others

Data availability

The datasets supporting the results of this article are included within the article.

References

Tricarico L, Spina R (2010) Experimental investigation of laser beam welding of explosion-welded steel/aluminum structural transition joints[J]. Mater Des 31(4):1981–1992

Tricarico L, Spina R, Sorgente D, Brandizzi M (2009) Effects of heat treatments on mechanical properties of Fe/Al explosion-welded structural transition joints[J]. Mater Des 30(7):2693–2700

Grydin O, Gerstein G, Nürnberger F, Schaper M, Danchenko V (2013) Twin-roll casting of aluminum-steel clad strips[J]. J Manuf Process 15(4):501–507

Chen G, Li J, Xu G (2017) Bonding process and interfacial reaction in horizontal twin-roll casting of steel/aluminum clad sheet[J]. J Mater Process Technol 246:1–12

Chen G, Xu G (2017) Effects of melt pressure on process stability and bonding strength of twin-roll cast steel/aluminum clad sheet[J]. J Manuf Process 29:438–446

**ao H, XU P, Qi Z, Wu Z, Zhao Y (2017) Preparation of steel/aluminum laminated composites by differential temperature rolling with induction heating[J]. Acta Metall Sin 56:231–239

Gao C, Li L, Chen X, Zhou D, Tang C (2016) The effect of surface preparation on the bond strength of Al-St strips in CRB process[J]. Mater Des 107:205–211

Wang C, Jiang Y, **e J, Zhou D, Zhang X (2016) Effect of the steel sheet surface hardening stateon interfacial bonding strength of embedded aluminum–steel composite sheet produced by cold roll bonding process[J]. Mater Sci Eng A 652:51–58

Akramifard HR, Mirzadeh H, Parsa MH (2014) Cladding of aluminum on AISI 304L stainless steel by cold roll bonding: mechanism, microstructure, and mechanical properties. Mater Sci Eng A 613:232–239

Wang C, Jiang Y, **e J, Zhou D, Zhang X (2017) Interface formation and bonding mechanism of embedded aluminum-steel composite sheet during cold roll bonding[J]. Mater Sci Eng A 708:50–59

Li MQ, Jiang FL, Zhang H, Li LX (2009) Deformation rule of steel/aluminum metal-laminate material during hot roll bonding[J]. Chin J Nonferrous Met 19(4):644–648

Huang H, Zhao Y, Wang C, Yan M (2019) Influence of plasma spraying on interfacial microstructure and mechanical property of thick steel/aluminum laminated plate by hot rolling[J]. J Mech Eng 14:30–36

Liu W, Ma J, Atabaki MM, Kovacevic R (2015) Joining of advanced high-strength steel to AA 6061 alloy by using Fe/Al structural transition joint[J]. Mater Des 68:146–157

Chen X, Li L, Zhou DJ (2015) Formation and bonding properties of al(4a60)-steel(08al) clad strip intermetallic compound[J]. Chin J Nonferrous Met 25(5):1176–1184

Fu L, **ao H, Yu C, Lv Q, Zhang S, **e H (2022) Bonding enhancement of cold rolling Al/steel composite plates via self-nano film modification[J]. J Mater Process Tech 300:117427

Funding

This project is supported by the National Natural Science Foundation of China (Grant No. 52005361), the Project funded by China Postdoctoral Science Foundation (Grant No. 2021M692373), the Open Project of the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology (Grant No. P2022-004), the Major Project of Science and Technology of Shanxi Province (Grant No. 20181102016), and the Natural Science Foundation of Shanxi Province (Grant No. 201901D211011).

Author information

Authors and Affiliations

Contributions

Ke Chen: methodology, experiment, data sorting, investigation, writing—original draft. Wenwen Liu: conceptualization, methodology, investigation, validation, writing—original draft, writing—review and editing, supervision, funding acquisition. Tao Wang: methodology, investigation, validation, investigation, writing—review and editing, funding acquisition. Na** Wang: investigation, writing—original draft. Zhongyu Chen: investigation, writing—original draft.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors agree with the participation.

Consent for publication

All the authors have reached agreement for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, K., Liu, W., Wang, T. et al. Experimental research on the technology of two-pass different temperature rolling for thick steel/aluminum/aluminum-alloy composite plate. Int J Adv Manuf Technol 120, 7689–7705 (2022). https://doi.org/10.1007/s00170-022-09120-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-09120-4