Abstract

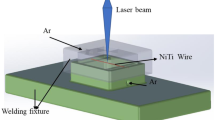

Numerous are the applications of NiTi shape memory alloys (SMA) in smart designs and structures. Many researchers and manufacturers investigate laser welding and joining process to integrate the functionalities of NiTi alloys, including superelasticity (SE) and shape memory effect (SME). Accordingly, this integration would provide better flexibility to that class of materials which can be applied in the development of multi-functional systems and components. The present study investigates the laser welding of dissimilar NiTi wires, including both SE and SME wires, using a high-power diode laser (HPDL). The resulting welded joints were investigated using various mechanical and microstructural analysis including optical microscopy (OM), scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS), differential scanning calorimetry (DSC), and tensile and micro-hardness tests. Various operational parameters, that is, laser power and speed, were investigated to obtain high-quality welded joints, preserve the transformation temperature of the welded zone, and, subsequently, minimize the influence of the welding process on the functionality of the joined materials.

Laser welding process of NiTi (SE) to NiTi (SME).

Similar content being viewed by others

References

Sathiya P, Ramesh T (2017) Experimental investigation and characterization of laser welded NiTinol shape memory alloys. J Manuf Process 25:253–261

Zeng Z, Yang M, Oliveira JP, Song D, Peng B (2016) Laser welding of NiTi shape memory alloy wires and tubes for multi-functional design applications. Smart Mater Struct 25(8):085001

Elahinia MH (2016) Shape memory alloy actuators: design, fabrication, and experimental evaluation. John Wiley & Sons, Chichester

Mehrpouya M, Cheraghi Bidsorkhi H (2016) MEMS applications of NiTi based shape memory alloys: a review. Micro and Nanosystems 8(2):79–91

Mehrpouya M, Shahedin AM, Daood Salman Dawood S, Kamal Ariffin A (2017) An investigation on the optimum machinability of NiTi based shape memory alloy. Mater Manuf Process 32(13):1497–1504

Mehrpouya M, Gisario A, Elahinia M (2018) Laser welding of NiTi shape memory alloy: a review. J Manuf Process 2018(31):162–186

Falvo A, Furgiuele F, Maletta C (2005) Laser welding of a NiTi alloy: Mechanical and shape memory behaviour. Mater Sci Eng A 412(1):235–240

Tam B, Khan M, Zhou Y (2011) Mechanical and functional properties of laser-welded Ti-55.8 Wt Pct Ni nitinol wires. Metall Mater Trans A 42(8):2166–2175

Elahinia MH, Hashemi M, Tabesh M, Bhaduri SB (2012) Manufacturing and processing of NiTi implants: a review. Prog Mater Sci 57(5):911–946

Zamani N, Khamesee MB, Khan MI (2017) Novel laser processed shape memory alloy actuator design with an embedded strain gauge sensor using dual resistance measurements. Part I: Fabrication and model-based position estimation. Sensors Actuators A Phys 263:234–245

Engeberg ED, Dilibal S, Vatani M, Choi JW, Lavery J (2015) Anthropomorphic finger antagonistically actuated by SMA plates, Bioinspir Biomim 10(5):056002

Gisario A, Mehrpouya M, Venettacci S, Mohammadzadeh A, Barletta M (2016) LaserOrigami (LO) of three-dimensional (3D) components: experimental analysis and numerical modelling. J Manuf Process 23:242–248

Gisario A, Veniali F, Barletta M, Tagliaferri V, Vesco S (2017) Laser transmission welding of poly (ethylene terephthalate) and biodegradable poly (ethylene terephthalate)–based blends. Opt Lasers Eng 90:110–118

Oliveira J et al (2016) Effect of laser welding parameters on the austenite and martensite phase fractions of NiTi. Mater Charact 119:148–151

Mehrpouya M, Lavvafi H, Darafsheh A (2018) Microstructural characterization and mechanical reliability of laser-machined structures. In: Lawrence J (ed) Advances in laser materials processing, 2nd edn, Woodhead Publishing, Sawston, pp 731–761

Gong W-h, Chen Y-h, Ke L-m (2011) Microstructure and properties of laser micro welded joint of TiNi shape memory alloy. Trans Nonferrous Metals Soc China 21(9):2044–2048

Chatterjee S, Abinandanan T, Chattopadhyay K (2006) Microstructure development during dissimilar welding: case of laser welding of Ti with Ni involving intermetallic phase formation. J Mater Sci 41(3):643–652

Bram M, Ahmad-Khanlou A, Heckmann A, Fuchs B, Buchkremer HP, Stöver D (2002) Powder metallurgical fabrication processes for NiTi shape memory alloy parts. Mater Sci Eng A 337(1-2):254–263

Wang W, Yang X, Li H, Cong F, Liu Y (2014) Effect of laser welding parameters on formation of NiTi shape memory alloy welds. Adv Mater Sci Eng 2014:1–8

Yan X, Yang D, Qi M (2006) Rotating–bending fatigue of a laser-welded superelastic NiTi alloy wire. Mater Charact 57(1):58–63

Dong P, Li H, Wang W, Zhou J (2018) Microstructural characterization of laser micro-welded Nitinol wires. Mater Charact 135:40–45

Frenzel J, George EP, Dlouhy A, Somsen C, Wagner MFX, Eggeler G (2010) Influence of Ni on martensitic phase transformations in NiTi shape memory alloys. Acta Mater 58(9):3444–3458

Adharapurapu R, Vecchio K (2007) Superelasticity in a new bioimplant material: Ni-rich 55NiTi alloy. Exp Mech 47(3):365–371

Zhang X, Sehitoglu H (2004) Crystallography of the B2→ R→ B19′ phase transformations in NiTi. Mater Sci Eng A 374(1-2):292–302

Chan C, Man H, Yue T (2012) Effect of post-weld heat-treatment on the oxide film and corrosion behaviour of laser-welded shape memory NiTi wires. Corros Sci 56:158–167

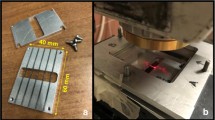

Mehrpouya M, Gisario A, Brotzu A, Natali S (2018) Laser welding of NiTi shape memory sheets using a diode laser. Opt Laser Technol 108:142–149

Oliveira J et al (2016) On the mechanisms for martensite formation in YAG laser welded austenitic NiTi. Shape memory and superelasticity 2(1):114–120

Hornbuckle B, Noebe R, Thompson G (2015) Influence of Hf solute additions on the precipitation and hardenability in Ni-rich NiTi alloys. J Alloys Compd 640:449–454

Pequegnat A, Michael A, Wang J, Lian K, Zhou Y, Khan MI (2015) Surface characterizations of laser modified biomedical grade NiTi shape memory alloys. Mater Sci Eng C 50:367–378

Mirshekari G et al (2015) Microstructure, cyclic deformation and corrosion behavior of laser welded NiTi shape memory wires. J Mater Eng Perform 24(9):3356–3364

Acknowledgments

The authors thank Dr. Elisa Pizzi for her assistance in the DSC test. Also, the authors would like to acknowledge Mr. Riccardo D’Amico and Mr. Attilio Panella for their contributions in the experimental tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mehrpouya, M., Gisario, A., Broggiato, G.B. et al. Effect of welding parameters on functionality of dissimilar laser-welded NiTi superelastic (SE) to shape memory effect (SME) wires. Int J Adv Manuf Technol 103, 1593–1601 (2019). https://doi.org/10.1007/s00170-019-03514-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03514-7