Abstract

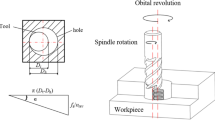

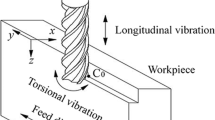

Compared with conventional hole-making process, rotary ultrasonic machining (RUM) is commonly believed to improve the cutting performance, such as low cutting force, good hole quality, long tool life, and high material removal rate. However, this work proposes an interesting observation on hole-making process using longitude-torsional ultrasonic assisted helical milling (LT UAHM). Due to the special kinematic motion in LT UAHM, the trajectory of the cutting tool has complex characteristics which may generate a negative effect on machining performance. In this study, a comparative experiment between LT UAHM and conventional helical milling (HM) was carried out. The results showed that the axial cutting force is not always reduced, the machined hole quality is also not improved consistently in LT UAHM. To comprehend the cutting mechanism of LT UAHM incisively, a kinematic trajectory model was proposed. By the theoretical kinematic trajectory model, LT UAHM can generate the ultrasonic elliptical cutting in the process, and the phase shift is a critical factor that can affect the elliptical trajectory shape even the vibration cutting direction of the tool’s cutting edge. The equivalent cutting angle and direction of friction between the rake face and chip in processing change accordingly. As a result, the magnitude of cutting force and machined hole quality in terms of burr height in this process will be significantly affected.

Similar content being viewed by others

References

M’Saoubi R, Axinte D, Soo SL, Nobel C, Attia H, Kappmeyer G, Engin S, Sim W-M (2015) High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann Manuf Technol 64:557–580. https://doi.org/10.1016/j.cirp.20-15.05.002

Pramanik A (2014) Problems and solutions in machining of titanium alloys. Int J Adv Manuf Technol 70:919–928. https://doi.org/10.1007/s00170-013-5326-x

Yang Y, Li M, Li K (2014) Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int J Adv Manuf Technol 70:1803–1811. https://doi.org/10.1007/s0017-0-013-5431-x

Schroeder PT (1998) Widening interest in twist drills. Mod Mach Shop 71:106–113

Li S, Qin X, ** Y, Sun D, Li Y (2018) A comparative study of hole-making performance by coated and uncoated WC/Co cutters in helical milling of Ti/CFRP stacks. Int J Adv Manuf Technol 94:2645–2658. https://doi.org/10.1007/s00170-017-0842-8

Dasch JM, Ang CC, Wong CA, Cheng YT, Weiner AM, Lev LC, Konca E (2006) A comparison of five categories of carbon-based tool coatings for dry drilling of aluminum. Surf Coat Technol 200:2970–2977. https://doi.org/10.1016/j.surfcoat.2–005.04.025

Barani A, Amini S, Paktinat H, Fadaei Tehrani A (2014) Built-up edge investigation in vibration drilling of Al2024-T6. Ultrasonics 54:1300–1310. https://doi.org/10.1016/j.ultras.2014.01.003

Ezugwu EO, Wang ZM (1997) Titanium alloys and their machinability—a review. J Mater Process Technol 68:262–274. https://doi.org/10.1016/S0924-0136(96)0003-0-1

Ulutan D, Ozel T (2011) Machining induced surface integrity in titanium and nickel alloys: a review. Int J Mach Tools Manuf 51:250–280. https://doi.org/10.1016/j.ijm-achtools.2010.11.003

Revuru RS, Posinasetti NR, VSN VR, Amrita M (2017) Application of cutting fluids in machining of titanium alloys—a review. Int J Adv Manuf Technol 91:2477–2498. https://doi.org/10.1007/s00170-016-9883-7

Lauderbaugh LK (2009) Analysis of the effects of process parameters on exit burrs in drilling using a combined simulation and experimental approach. J Mater Process Technol 209:1909–1919. https://doi.org/10.1016/j.jmatprotec.2008.04.062

Dornfeld DA, Kim JS, Dechow H, Hewson J, Chen LJ (1999) Drilling burr formation in titanium alloy, Ti-6AI-4V. CIRP Ann Manuf Technol 48:73–76. https://doi.org/10.1016/S0007-8506(07)63134-5

Rivero A, Aramendi G, Herranz S, de Lacalle LL (2006) An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int J Adv Manuf Technol 28:1–11. https://doi.org/10.1007/s00170-004-2349-3

Li Z, Zhang D, Jiang X, Qin W, Geng D (2017) Study on rotary ultrasonic-assisted drilling of titanium alloys (Ti6Al4V) using 8-facet drill under no cooling condition. Int J Adv Manuf Technol 90:3249–3264. https://doi.org/10.1007/s00170-016-9593-1

Pecat O, Brinksmeier E (2014) Tool wear analyses in low frequency vibration assisted drilling of CFRP/Ti6Al4V stack material. Procedia CIRP 14:142–147. https://doi.org/10.1016/j.procir.2014.03.050

Sanda A, Arriola I, Garcia Navas V, Bengoetxea I, Gonzalo O (2016) Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V. J Manuf Process 22:169–176. https://doi.org/10.1016/j.jmapro.2016.03.003

Azarhoushang B, Akbari J (2007) Ultrasonic-assisted drilling of Inconel 738-LC. Int J Mach Tools Manuf 47:1027–1033. https://doi.org/10.1016/j.ijmachtools.2006.10.007

Lotfi M, Amini S (2017) Experimental and numerical study of ultrasonically-assisted drilling. Ultrasonics 75:185–193. https://doi.org/10.1016/j.ultras.2016.11.009

Amini S, Soleimani M, Paktinat H, Lotfi M (2017) Effect of longitudinal−torsional vibration in ultrasonic-assisted drilling. Mater Manuf Process 32:616–622. https://doi.org/10.1080/10426914.2016.1198027

Paktinat H, Amini S (2018) Numerical and experimental studies of longitudinal and longitudinal-torsional vibrations in drilling of AISI 1045. Int J Adv Manuf Technol 94:2577–2592. https://doi.org/10.1007/s00170-017-0893-x

Wang J, Zhang J, Feng P, Guo P, Zhang Q (2018) Feasibility study of longitudinal–torsional-coupled rotary ultrasonic machining of brittle material. J Manuf Sci Eng-Trans ASME 140:051008–051008–051011. https://doi.org/10.1115/1.4038728

Sasahara H, Kawasaki M, Tsutsumi M (2008) Helical feed milling with MQL for boring of aluminum alloy. J Adv Mech Des Syst Manuf 2:1030–1040. https://doi.org/10.1299/jamdsm.2.1030

Olvera D, de Lacalle LNL, Urbikain G, Lamikiz A, Rodal P, Zamakona I (2012) Hole making using ball helical milling on titanium alloys. Mach Sci Technol 16:173–188. https://doi.org/10.1080/10910344.2012.673958

Li H, He G, Qin X, Wang G, Lu C, Gui L (2014) Tool wear and hole quality investigation in dry helical milling of Ti-6Al-4V alloy. Int J Adv Manuf Technol 71:1511–1523. https://doi.org/10.1007/s00170-013-5570-0

Moriwaki T, Shamoto E (1995) Ultrasonic elliptical vibration cutting. CIRP Ann Manuf Technol 44:31–34. https://doi.org/10.1016/S0007-8506(07)62269-0

** X, Koya NG (2016) Prediction of coupled torsional–axial vibrations of drilling tool with clam** boundary conditions. CIRP Ann Manuf Technol 13:24–36. https://doi.org/10.1016/j.cirpj.2016.02.001

Li X, Zhang D (2006) Ultrasonic elliptical vibration transducer driven by single actuator and its application in precision cutting. J Mater Process Technol 180:91–95. https://doi.org/10.1016/j.jmatprotec.2006.05.007

Shamoto E, Moriwaki T (1994) Study on elliptical vibration cutting. CIRP Ann Manuf Technol 43:35–38. https://doi.org/10.1016/S0007-8506(07)62158-1

Ma C, Ma J, Shamoto E, Moriwaki T (2011) Analysis of regenerative chatter suppression with adding the ultrasonic elliptical vibration on the cutting tool. Precis Eng-J Int Soc Precis Eng Nanotechnol 35:329–338. https://doi.org/10.1016/j.precis-ioneng.2010.12.004

Ma C, Shamoto E, Moriwaki T, Zhang Y, Wang L (2005) Suppression of burrs in turning with ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 45:1295–1300. https://doi.org/10.1016/j.ijmachtools.2005.01.011

Ma C, Shamoto E, Moriwaki T, Wang L (2004) Study of machining accuracy in ultrasonic elliptical vibration cutting. Int J Mach Tools Manuf 44:1305–1310. https://doi.org/10.1016/j.ijmachtools.2004.04.014

Funding

This work is supported by the National Natural Science Foundation of China (Grant No. 51575384) and the Natural Science Foundation of Tian** (Grant Nos. 16JCQNJC04600 and 16JCZDJC38300).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zou, Y., Chen, G., Lu, L. et al. Kinematic view of cutting mechanism in hole-making process of longitude-torsional ultrasonic assisted helical milling. Int J Adv Manuf Technol 103, 267–280 (2019). https://doi.org/10.1007/s00170-019-03483-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03483-x