Abstract

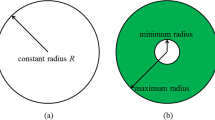

In this study, parallelism errors between the spindle axis and the linear axis of machine tools were measured using a double ball-bar. Specifically, two circular tests were performed to measure the parallelism errors using tool balls with different tool lengths and a workpiece ball fixed to a workpiece table. Parallelism errors were calculated by analyzing, simultaneously, the measured double ball-bar (DBB) data from the circular tests. The proposed method provides accurate measurements due to a large offset between the circular tests within the working space of machine tools. Additionally, the approach only requires a DBB and adjustment/extension fixtures; thus, it simplifies measurements and is cost-effective.

Similar content being viewed by others

References

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40(9):1235–1256

Lee KI, Lee DM, Yang SH (2012) Parametric modeling and estimation of geometric errors for a rotary axis using double ball-bar. Int J Adv Manuf Technol 62(5–8):741–750

**ang S, Yang J, Zhang Y (2014) Using a double ball bar to identify position-independent geometric errors on the rotary axes of five-axis machine tools. Int J Adv Manuf Technol 70:2071–2082

ISO 230–1 (2012) “Test code for machine tools—part 1: geometric accuracy of machines operating under no-load or quasi-static conditions,” ISO

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines—an update. CIRP Ann Manuf Technol 57(2):660–675

Ibaraki S, Knapp W (2012) Indirect measurement of volumetric accuracy for three-axis and five-axis machine tools: a review. Int J Autom Technol 6(2):110–124

ISO 230–7 (2006) “Test code for machine tools—part 7: geometric accuracy of axes of rotation,” 2006

Tu JF, Bossmanns B, Hung SCC (1997) Modeling and error analysis for assessing spindle radial error motions. Precis Eng 21(2–3):90–101

Lee ES, Wi HG (1998) A comprehensive technique for measuring the three-dimensional positioning accuracy of a rotating object. Int J Adv Manuf Technol 14(5):330–335

Castro HFF (2008) A method for evaluating spindle rotation errors of machine tools using a laser interferometer. Measurement 41(5):526–537

Liu CH, Jywe WY, Lee HW (2004) Development of a simple test device for spindle error measurement using a position sensitive detector. Meas Sci Technol 15(9):1733–1741

Jywe WY, Chen CJ (2005) The development of a high-speed spindle measurement system using a laser diode and a quadrants sensor. Int J Mach Tools Manuf 45(10):1162–1170

Jywe WY, Chen CJ (2007) A new 2D error separation technique for performance tests of CNC machine tools. Precis Eng 31(4):369–375

ISO 10791–2 (2001) “Test conditions for machining centres—part 2: geometric tests for machines with vertical spindle or universal heads with vertical primary rotary axis,” ISO

Lee KI, Yang SH (2014) Circular tests for accurate performance evaluation of machine tools via an analysis of eccentricity. Int J Precis Eng Manuf 15(12):2499–2506

Lee KI, Yang SH (2013) Measurement and verification of position-independent geometric errors of a five-axis machine tool using a double ball-bar. Int J Mach Tools Manuf 70:45–52

ISO 230–2 (2006) “Test code for machine tools—part 2: determination of accuracy and repeatability of positioning numerically controlled axes,” ISO

Lee DM, Zhu Z, Lee KI, Yang SH (2011) Identification and measurement of geometric errors for a five-axis machine tool with a tilting head using a double ball-bar. Int J Precis Eng Manuf 12(2):337–343

ISO/TR 230–9 (2005) “Test code for machine tools—part 9: estimation of measurement uncertainty for machine tool tests according to series ISO 230, Basic Equations,” ISO

Lee DM, Cha YT, Yang SH (2010) Analysis of eccentricity in the ball bar measurement. J Mech Sci Technol 24(1):271–274

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, KI., Shin, DH. & Yang, SH. Parallelism error measurement for the spindle axis of machine tools by two circular tests with different tool lengths. Int J Adv Manuf Technol 88, 2883–2887 (2017). https://doi.org/10.1007/s00170-016-8999-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8999-0