Abstract

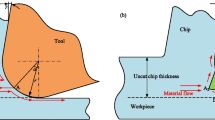

The aim of the paper is the modeling of chip formation in metal cutting in order to describe the thermomechanical interactions at the tool-chip interface (TCI). A particular attention is paid for the fully sticking case to complete previous modeling works which were more focused on the sliding regime or mixed sliding/sticking regime. The fully sticking contact is dominating due to the combined effects of high magnitudes of the normal stress, the average friction coefficient \( \left(\overline{\upmu}\to 1\right) \) and the temperature. This case is also well adapted for cutting of titanium alloy. In the present model, these local parameters are macroscopically expressed through the average friction coefficient \( \overline{\upmu} \), and the velocity field on the secondary shear zone is modeled using a new approach. The ratio between real area of contact A r and the apparent area A n is taken into consideration. The developed approach is also fully thermomechanically coupled with heat transfer consideration. In this way, it was possible to predict normal and shear stress according to the variation of cutting velocities, feed and rake angle. The model was supported by the experimental trends from Ti6Al4V alloy cutting tests and worn tools analysis. It was shown that the distribution of the ratio A r /A n may be considered as a good indicator to describe the spreading of the adhesion marks on the contact. The model also highlights how the influence of the apparent friction coefficient, the rake angle, the feed and the cutting speed acts on the tool-chip contact length.

Similar content being viewed by others

References

Usui E, Shirakashi T (1982) Mechanics of machining—from “descriptive” to “predictive” theory, on the art of cutting metals—75 years later. ASME PE 7:13–35

Childs THC, Mahdi MI, Barrow G (1989) On the stress distribution between the chip and tool during metal turning. CIRP Ann Manuf Technol 38:55–58

Kato S, Yamaguchi K, Yamada M (1972) Stress distribution at the interface between tool and chip in machining. J Manuf Sci Eng 94:683–689

Bagchi A, Wright PK (1987) Stress analysis in machining with the use of sapphire tools. Proc R Soc Lond A Math Phys Sci 409:99–113

Amini E (1968) Photoelastic analysis of stresses and forces in steady cutting. J Strain Anal Eng Des 3:206–213

Usui E, Takeyama H (1960) A photoelastic analysis of machining stresses. J Manuf Sci Eng 82:303–307

Sutter G, Ranc N (2007) Temperature fields in a chip during high-speed orthogonal cutting—an experimental investigation. Int J Mach Tools Manuf 47:1507–1517

M’saoubi R, Lebrun JL, Changeux B (1998) A new method for cutting tool temperature measurement using CCD infrared technique: influence of tool and coating. Mach Sci Technol 2:369–382

Battaglia J-L, Cois O, Puigsegur L, Oustaloup A (2001) Solving an inverse heat conduction problem using a non-integer identified model. Int J Heat Mass Transf 44:2671–2680

Trent EM (1988) Metal cutting and the tribology of seizure: III temperatures in metal cutting. Wear 128:65–81

Merchant ME (1945) Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J Appl Phys 16:267–275

Merchant ME (1945) Mechanics of the metal cutting process. II. Plasticity conditions in orthogonal cutting. J Appl Phys 16:318–324

Astakhov VP (2006) Tribology of metal cutting, Elsevier

Oxley PLB (1989) The mechanics of machining: an analytical approach to assessing machinability, E. Horwood

Zorev NN (1966) Metal cutting mechanics, Pergamon Press

Trent EM (1988) Metal cutting and the tribology of seizure: I seizure in metal cutting. Wear 128:29–45

Trent EM, Wright PK (2000) Metal cutting, Butterworth-Heinemann

Wright PK, Horne JG, Tabor D (1979) Boundary conditions at the chip-tool interface in machining: comparisons between seizure and sliding friction. Wear 54:371–390

El Mansori M, Mkaddem A (2007) Surface plastic deformation in dry cutting at magnetically assisted machining. Surf Coat Technol 202:1118–1122. doi:10.1016/j.surfcoat.2007.07.104

Molinari A, Cheriguene R, Miguélez H (2011) Numerical and analytical modeling of orthogonal cutting: the link between local variables and global contact characteristics. Int J Mech Sci 53:183–206

Marinov VR (2001) Hybrid analytical–numerical solution for the shear angle in orthogonal metal cutting—part I: theoretical foundation. Int J Mech Sci 43:399–414

Marinov VR (2001) Hybrid analytical–numerical solution for the shear angle in orthogonal metal cutting—part II: experimental verification. Int J Mech Sci 43:415–426

S. Bahi, Modélisation hybride du frottement local à l’interface outil-copeau en usinage des alliages métalliques. Ph.D. Thesis (in french). https://pastel.archives-ouvertes.fr/pastel-00602396.

Bahi S, Nouari M, Moufki A, Mansori ME, Molinari A (2012) Hybrid modelling of sliding–sticking zones at the tool–chip interface under dry machining and tool wear analysis. Wear 286:45–54

Bahi S, Nouari M, Moufki A, El Mansori M, Molinari A (2011) A new friction law for sticking and sliding contacts in machining. Tribol Int 44:764–771

Bowden FP, Tabor D (1939) The area of contact between stationary and between moving surfaces, in: Proc R Soc Lond A Math Phys Sci. pp. 391–413

Childs THC, Maekawa K, Obikawa T, Yamane Y (2000) Metal Machining: Theory and Applications, Butterworth-Heinemann

Gerth J, Gustavsson F, Collin M, Andersson G, Nordh L-G, Heinrichs J et al (2014) Adhesion phenomena in the secondary shear zone in turning of austenitic stainless steel and carbon steel. J Mater Process Technol 214:1467–1481

Childs THC (2006) Friction modelling in metal cutting. Wear 260:310–318

Finnie I, Shaw MC (1956) The friction process in metal cutting. Trans ASME 78:1649

Sutter G, List G (2013) Very high speed cutting of Ti6Al4V titanium alloy—change in morphology and mechanism of chip formation. Int J Mach Tools Manuf 66:37–63

Arnoux J-J, Sutter G, List G (2012) Characterization of Dynamic Friction Factor for FEM Modeling of High Speed Process

Qi HS, Mills B (2000) Formation of a transfer layer at the tool-chip interface during machining. Wear 245:136–147

M’Saoubi R, Chandrasekaran H (2005) Innovative methods for the investigation of tool-chip adhesion and layer formation during machining. CIRP Ann Manuf Technol 54:59–62

Wiklund U, Rubino S, Kádas K, Skorodumova NV, Eriksson O, Hedberg S et al (2011) Experimental and theoretical studies on stainless steel transfer onto a TiN-coated cutting tool. Acta Mater 59:68–74

Oxley PLB, Hastings WF (1976) Minimum work as a possible criterion for determining the frictional conditions at the tool/chip interface in machining. Philos Trans R Soc London Ser Math Phys Sci 282:565–584

Bao H, Stevenson MG (1976) An investigation of built-up edge formation in the machining of aluminium. Int J Mach Tool Des Res 16:165–178

Dudzinski D, Molinari A (1997) A modelling of cutting for viscoplastic materials. Int J Mech Sci 39:369–389

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, in: Proc. 7th Int. Symp. Ballist. pp. 541–547

Moufki A, Molinari A, Dudzinski D (1998) Modelling of orthogonal cutting with a temperature dependent friction law. J Mech Phys Solids 46:2103–2138

Lim SC, Ashby MF (1987) Overview no. 55 wear-mechanism maps. Acta Metall 35:1–24

Grzesik W, Nieslony P (2003) A computational approach to evaluate temperature and heat partition in machining with multilayer coated tools. Int J Mach Tools Manuf 43:1311–1317

Boivineau M, Cagran C, Doytier D, Eyraud V, Nadal M-H, Wilthan B (2006) Propriétés thermophysiques de l’alliage Ti6Al4V (TA6V) à l’état solide et liquide. Int J Thermophys 27(2):507–529

Zvorykin KA (1893) Work and stress necessary for separation of metal chips. Proc. Kharkov Technol. Inst, Ukr

Gras R, Courtel R (1973) Frottement à haute température du titane et de l’alliage TA6V. Wear 26:1–26

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bahi, S., List, G. & Sutter, G. Modeling of friction along the tool-chip interface in Ti6Al4V alloy cutting. Int J Adv Manuf Technol 84, 1821–1839 (2016). https://doi.org/10.1007/s00170-015-7752-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7752-4