Abstract

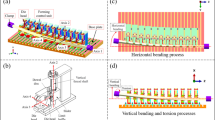

Most rapid prototy** (RP) processes adopt a solid CAD model sliced into thin layers of constant thickness in the building direction. Each cross-sectional layer is successively deposited and, simultaneously, bonded onto the previous layer; eventually the stacked layers form a physical part of the model. A new RP process called the Transfer-type Variable Lamination Manufacturing process using expandable polystyrene foam sheet (VLM-st) has been developed to reduce building time and to improve the surface finish of parts with thick layers and slo** surfaces. The objective of this study is to develop a method for calculating the rotation angles (θ x, θ y ) of a linear hotwire cutter in the three-dimensional space for the VLM-st process using inverse kinematics. The method for calculating the rotation angles (θ x , θ y ) of the four-axis hotwire cutter to VLM-st was applied and verified for a variety of free surface bodies.

Similar content being viewed by others

References

Jacobs PF (1996) Stereolithography and other RP&M technologies from rapid prototy** to rapid tooling. ASME Press, New York

Wohlers TT (2001) Rapid prototy** & tooling state of the industry. Wohlers report, Wohlers Assoc.

Kulkarni P, Marsan A, Dutta D (2000) A review of process planning techniques in layered manufacturing. Rapid Prototy** J 6(1):18–35

Novc A, Kaza S, Wang Z, Thomas C (1996) Techniques for improved speed accuracy in layered manufacturing. Solid Freeform Fabrication Symposium Proceedings, UT Austin, Texas, pp 609–617

Chamberlain PB, Von Roosendaal MD, Thomas CL (1998) Variable thickness ruled edge slice generation and three-dimensional graphical error visualization. Solid Freeform Fabrication Symposium Proceedings, UT Austin, Texas, pp 311–318

Chamberlain PB, Thomas CL (1999) Direct thick layer rapid prototy** from medical images. Solid Freeform Fabrication Symposium Proceedings, UT Austin, Texas, pp 599–605

Hope RL, Jacobs PA, Roth RN (1997) Rapid prototy** with slo** surfaces. Rapid Prototy** J 3(1):12–19

Hope RL, Roth RN, Jacobs PA (1997) Adaptive slicing with slo** layer surface. Rapid Prototy** J 3(3):89–98

Zheng Y, Choi S, Mathewson B, Newman W (1996) Progress in computer-aided manufacturing of laminated engineering materials utilizing thick, tangent-cut layers. Solid Freeform Fabrication Symposium, UT Austin, Texas, pp 355–362

Zheng Y, Newman WS (1997) Software design challenges for computer-aided manufacturing of laminated engineering materials (CAM-LEM). Proceedings of the 6th European Conference on Rapid Prototy** and Manufacturing, Nottingham, UK, pp 21–30

Variable lamination manufacturing (VLM) process and apparatus. U.S. Patent Application Number 09/804, 175

Transfer type variable lamination manufacturing by using linear heat cutting system and apparatus. Korea Patent Application Number 2001–0040212

Lee SH, Kim TH, Ahn, Yang DY, Chae HC (2001) Software development for automatic generation of unit shape part for variable lamination manufacturing process. Korean Society of Precision Engineering 18(8):64–70

Ahn DG, Lee SH, Yang DY (2001) Investigation into thermal characteristics of linear hotwire cutting system for variable lamination manufacturing (VLM). Int J Mach Tool Manu 42:427–538

Acknowledgement

The authors would like to acknowledge the financial assistance of the Ministry of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, S.H., Ahn, D.G. & Yang, D.Y. Calculation and verification of rotation angle of a four-axis hotwire cutter for transfer-type variable lamination manufacturing using expandable polystyrene foam. Int J Adv Manuf Technol 22, 175–183 (2003). https://doi.org/10.1007/s00170-002-1456-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-002-1456-2