Abstract

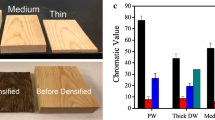

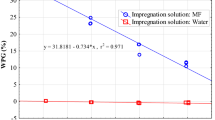

According to recent literature, delignification could be a new approach to enhance mechanical properties of densified wood. In the present study, the effect of delignification and polymerization, on the physical properties and chemical structure of densified poplar wood was investigated. Wood blocks were delignified with glycerol, in order to keep the hemicelluloses, as an important component in hydrogen and ester bond formation during densification. Afterwards, the delignified blocks were immersed in glycerol-maleic anhydride solution and compressed at 100 °C for 24 h. Results of infrared spectroscopy (FTIR) and scanning electron microscopy (SEM) confirmed the changes in the chemical and morphological structure of delignified wood. Removal of lignin increased hydrogen bonds formation between the adjacent fibers during pressing and reduced the set recovery of the compressed product up to 2%. The set recovery of densified samples was further significantly decreased following surface polymerization with glycerol and maleic anhydride (68% lower than the non-polymerized ones). Combined delignification/polymerization increased the specific tensile strength of densified samples by 37% as compared to non-densified ones.

Similar content being viewed by others

References

Ando K, Onda H (1999) Mechanism for deformation of wood as a honeycomb structure I: effect of anatomy on the initial deformation process during radial compression. J Wood Sci 45:120–126

Bao M, Huang X, Jiang M, Yu W, Yu Y (2017) Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood (Populus tomentosa). J Wood Sci 63:591–605

Barone JR, Arikan O (2007) Composting and biodegradation of thermally processed feather keratin polymer. Polym Degrad Stab 92(5):859–867

Bektas I, Guler C, Kalaycioglu H, Mengeloglu F, Nakar M (2005) The manufacture of particle boards using sunflowers stalks (Helianthus annuus L) and poplar wood (Populus Alba L). J Compos Mater 39(5):467–473

Boonstra MJ, Blomberg J (2007) Semi-isostatic densification of heat-treated radiata pine. Wood Sci Technol 41:607–617

Cavus V (2020) Selected properties of Mahogany wood flour filled polypropylene composite: the effect of maleic anhydride-graft polypropylene (MAPP). BioResources 15(2):2227–2236

Chen H, Ferrari F, Angiuli M, Yao J, Raspi C, Bramanti E (2010) Qualitative and quantitative analysis of wood samples by Fourier transform infrared spectroscopy and multivariate analysis. Carbohydr Polym 82:772–778

Chotirotsukon C, Marisa R, Verawat C, Navadol L (2019) Fractionation of sugarcane trash by oxalic-acid catalyzed glycerol-based organosolv followed by mild solvent delignification. Ind Crops Prod 141:1–9

Demirbas A (1998) Aqueous glycerol delignification of wood chips and ground wood. Bioresour Technol 63(2):179–185

Esteves B, Velez Marques A, Domingos I, Pereira H (2006) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci Technol 41:193–207

Esteves B, Domingos I, Pereira H (2007) Improvement of technological quality of eucalypt wood by heat treatment in air at 170–200 °C. Forest Prod J 57:47–52

Fernandez-Rodriguez J, Erdocia X, Hernandez-Ramos F, Gordobil O, Alriolz MG, Labidi J (2020) Direct lignin depolymerization process from sulfur-free black liquors. Fuel Process Technol 197:1–11

Frey M, Widner D, Segmehl JS, Casdorff K, Keplinger T, Burgert I (2018) Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS Appl Mater Interfaces 10(5):5030–5037

Fu Q, Cloutier A, Laghdir A (2016) Optimization of the thermo-hygro mechanical (THM) process for sugar maple wood densification. BioResources 11(4):8844–8859

Gonultas O, Candan Z (2018) Chemical characterization and ftir spectroscopy of thermally compressed eucalyptus wood panels. Maderas Ciencia y Tecnología 20(3):422–431

Hajihassani R, Mohebby B, Najafi SK, Navi P (2018) Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Maderas Cienc Tecnol 20(1):117–128

Ito Y, Tanahashi M, Shigematsu M, Shinoda Y, Ohta C (1998) Compressive-molding of wood by high-pressure steam-treatment: Part 1. Development of compressively molded squares from thinnings. Holzforschung 52(2):211–216

Karadeniz N, Tiril A, Baylan E (2009) Wetland management in Turkey: problems, achievements and perspectives. Afr J Agric Res 4(11):1106–1119

Kazi SN (2018) Pulp and paper processing, 5th edn. IntechOpen Limited, Malaya

Keplinger T, Frey M, Burgert I (2018) Versatile strategies for the development of wood-based functional materials. In: Proceedings SPIE 10593, Bio inspiration. Biomimetics and Bio replication VIII. vol. 10593. https://doi.org/10.1117/12.2296537

Kutnar A, Kamke FA (2012) Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci Technol 46:953–964

Laine K, Belt T, Rautkari L, Ramsay J, Hill CAS, Hughes M (2013) Measuring the thickness swelling and set-recovery of densified and thermally modified Scots pine solid wood. J Mater Sci 48:8530–8538

Laine K, Segerholm K, Walinder M, Rautkari L, Hughes M (2016) Wood densification and thermal modification: hardness, set-recovery and micromorphology. Wood Sci Technol 50:883–894

Lee FY, Htar TT, Akowoah GA (2015) ATR-FTIR and spectrometric methods for the assay of crocin in commercial saffron spices (Crocus savitus L.). Int J Food Prop 18(8):1773–1783

Lykidis C, Kotrotsiou K, Tsichlakis A (2020) Reducing set-recovery of compressively densified poplar wood by impregnation–modification with melamine–formaldehyde resin. Wood Mater Sci Engin 15(5):269–277

Morsing N, Hoffmeyer P (1998) Densification of wood: the influence of hygrothermal treatment on compression of beech perpendicular to gain. Kgs. Technical University of Denmark, Denmark (BYG-Rapport; No. R-79)

Paukszta D, Doczekalaska B, Ostrowski A, Bartkowiak M (2014) Modification of rapeseed straw with organic acid anhydrides. J Compos Mater 49(11):1369–1378

Pelit H, Yalçın M (2017) Resistance of mechanically densified and thermally post-treated pine sapwood to wood decay fungi. J Wood Sci 63:514–522

Rautkari R, Hughes M (2009) Eliminating set-recovery in densified wood using a steam heat-treatment process. European conference on wood modification. Forest Products Technology. Helsinki University of Technology, Espoo

Rodrigues J, Faix O, Pereira H (1998) Determination of lignin content of eucalyptus glotylus wood using FTIR spectroscopy. Holzforschung 52:46–50

Romani A, Ruiz HA, Pereira FP, Domingues L, Teixeira JA (2013) Fractionation of eucalyptus globulus wood by glycerol−water pretreatment: optimization and modeling. Am Chem Soc 52:14342–14352

Roussel C, Marchetti V, Lemor A, Wozniak E, Loubinoux B, Gerardin P (2001) Chemical modification of wood by polyglycerol-maleic anhydride treatment. Holzforschung 55:57–62

Sandberg D, Haller P, Navi P (2013) Thermo-hydro and thermo-hydro-mechanical wood processing: an opportunity for future environmentally friendly wood products. Wood Mater Sci Eng 8(1):64–88

Schwarzkopf M (2021) Densified wood impregnated with phenol resin for reduced set-recovery. Wood Mater Sci Engin 16(1):35–41

Segneanu AE, Gozescu I, Dabici A, Sfirloaga P, Szabadai Z (2012) Organic compounds FT-IR spectroscopy. In: Macro to nano spectroscopy. InTech, Romania, pp 145–164

Song J, Chen C, Zhu S, Zhu M, Dai J, Ray U, Yao Y (2018) Processing bulk natural wood into a high-performance structural material. Nat 554:224–228

Sun F, Chen H (2008) Enhanced enzymatic hydrolysis of wheat straw by aqueous glycerol pretreatment. Biores Technol 99:6156–6161

Todaka M, Kowhakul W, Masamoto H, Shigematsu M (2019) Delignification of softwood by glycerol from biodiesel by-product I: model reaction using glycerol and fatty acid sodium soap mixture for pretreatment on bioethanol production. J Wood Sci 65(49):1–9

Tu D, Su X, Zhang T, Fan W, Zhou Q (2014) Thermo mechanical densification of populus tomentosa var. tomentosa with low moisture content. BioResources 9(3):3846–3856

Yang K, Peng H, Wen Y, Li N (2010) Re-examination of characteristic FTIR spectrum of secondary layer in bilayer oleic acid-coated Fe3O4 nanoparticles. Appl Surf Sci 256:3093–3097

Yang H, Gao M, Wang J, Mu H, Qi D (2021) Fast Preparation of high-performance wood materials assisted by ultrasonic and vacuum impregnation. Forests 12(5):567–579

Yue K, Wu J, Xu L, Tang Z, Chen Z, Liu W, Wang L (2020) Use impregnation and densification to improve mechanical properties and combustion performance of Chinese fir. Constr Build Mater 241:1–8

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yahyaee, S.M.H., Dastoorian, F., Ghorbani, M. et al. Combined effect of organosolv delignification/polymerization on the set recovery of densified poplar wood. Eur. J. Wood Prod. 80, 367–375 (2022). https://doi.org/10.1007/s00107-021-01756-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01756-5