Abstract

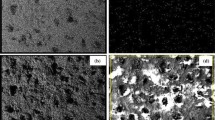

In this study, nanocrystalline NiAl intermetallic compound was obtained by mechanical alloying and PAS (plasma activated sintering method). Nanocrystalline NiAl powder was fabricated after 30 hr of milling with 2 wt.% stearic acid added as a PCA (process control agent) to the Ni-50at%Al composition. The grain size of the nanocrystalline NiAl powder was about 10 nm. Nanocrystalline NiAl powder was consolidated at 1000°C, 1100°C, 1200°C and 1300°C for 2 min with 30 MPa compressive force. The surface morphology of the NiAl consolidated at 1300°C was very regular and dense, above 96% of theoretical density (5.9 g/cm3). Al4C3 was observed in the NiAl consolidated at 1300°C by TEM analysis. It is thought that the carbons came from the stearic acid during the MA process and the graphite mold during the PAS process. The grain size of the NiAl consolidated at 1300°C did not increase but the grain shape became flat due to compressive force.

Similar content being viewed by others

References

D. M. Shah and D. L. Anton,JOM 44, 6 (1992).

R. Darolia,JOM 43, 44 (1991).

I. Baker, P. Nagpal, F. Liu, and P. R. Munroe,Acta metall. 39, 1637 (1991).

R. Darolia, J. J. Lewandowski, C. T. Liu, P. L. Martin, D. B. Miracle, and M. V. Nathal,Structural Intermetallics, TMS, Warrendale (1993).

T. Cheng,Scripta metall. mater. 31, (1994).

E. M. Schulson and D. R. Baker,Scripta metall. 17, 519 (1983).

M. A. Venkataswamy, J. A. Schneider, J. R. Groza, A. K. Mukherjee, K. Yamazaki, and K. Shoda,Mater. Sci. Eng. A 207, 153 (1996).

S. G. Pyo, N. J. Kim, and P. Nash,Mater. Sci. Eng. A 181–182, 1169 (1994).

S. Suh and M. Dollar,Scripta metall. mater. 31, 1663 (1994).

J. R. Groza,Scripta metall. mater. 30, 47 (1994).

C. H. Liu and P. W. Kao,Scripta metall. mater. 24, 2279 (1990).

J. R. Groza, S. H. Risbud, and K. Yamazaki,Plasma Synthesis and Processing of TMS (1993).

B. D. Cullity,Elements of X-ray Diffraction, 2nd ed, p. 101, Addison-Wesley Publ. Co. (1978).

J. R. Ryu, K. I. Moon, and K. S. Lee,J. Alloys & Compounds 296, 157 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, J.W., Kang, S.G. PAS consolidating behavior of mechanically alloyed nanocrystalline NiAl intermetallic compound. Met. Mater. Int. 9, 93–97 (2003). https://doi.org/10.1007/BF03027236

Issue Date:

DOI: https://doi.org/10.1007/BF03027236