Abstract

Thermal tempering is widely used to manufacture safety glass for economic as well as for certain safety measures. Laboratory investigations of the tempering process and the resultant strengthening effect are generally limited to rectangular specimens. Results are, therefore, appropriate for this particular geometry. This paper describes a simple stress-state model of a tempered flat glass specimen. the model, developed using photoelastic equations to determine the three-dimensional stress components, was used to predict the transient birefringence in a rectangular glass specimen subjected to uniform and symmetrical heat-transfer conditions, at a temperature where glass behaves as a perfect elastic material with no stress relaxation within the experimental time. A method of determining the coefficient of heat-transfer rate was then developed based on the analysis of the transient birefringence. This technique uses the glass specimen as an optical transducer, and does not affect, in any way, the natural flow of heat by forced convection or contact cooling.

Similar content being viewed by others

Abbreviations

- C o :

-

stress-optical coefficient

- c :

-

subscript for central mid-plane value, specific heat

- Δd :

-

scattered-light fringe separation

- E :

-

Young's modulus

- h 1 ,h 2 ,h 3 :

-

coefficient of heat-transfer rate in directionsx 1 ,x 2 andx 3 , respectively

- K :

-

constant

- k :

-

true thermal conductivity

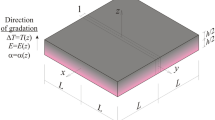

- \(2\ell _1 \) :

-

length

- \(2\ell _2 \) :

-

width

- \(2\ell _3 \) :

-

thickness

- s :

-

subscript for surface value, half thickness

- R 1 ,R 2 ,R 3 :

-

relative retardations in polarized light propagating alongx 1 ,x 2 andx 3 respectively

- x 1 ,x 2 ,x 3 :

-

Cartesian coordinates

- α:

-

coefficient of linear thermal expansion

- \(\beta = \frac{k}{{\rho c}}\) :

-

thermal diffusivity

- θ:

-

excess temperature over the ambient at any time

- θ i :

-

initial excess temperature

- ϱ:

-

density

- σ1, σ2, σ3 :

-

principal stresses

- σ i j, σ i k :

-

components of principal stress σ i alongi due to the heat flow alongj andk, respectively,i # j # k

- λ:

-

wavelength of light

- ν:

-

Poisson's ratio

- τ:

-

time in seconds

References

Pindera, J.T. andSinha, N.K., “Determination of Dominant Radiation in Polariscope by Means of Babinet Compensator,”Experimental Mechanics,12 (1),38–42 (Jan.1972).

Bateson, S., Hunt, J.W., Dalby, D.A. andSinha, N.K., “Stress Measurements in Tempered Glass Plates by Scattered Light Method with a Laser Source,”Bull. A. Ceram. Soc.,45 (2),193–198 (1966).

Bartenev, G., Theory of the Mechanical Strengthening of Glass by Annealing, (Russian),Doklady Akad. Nauk, S.S.S.R.,60, (2),257–260 (1948);“Investigation of Tempered Glass” (Russian), J. Tech. Phys., S.S.S.R.,XIX (12) (1949).

Aggarwala, B.D. andSaibal, E., “Tempering Stresses in An Infinite Glass Plate,”Phys. Chem. Glasses,2 (5),137–140 (1961).

Lee, E.H., Rogers, T.G. andWoo, T.C., “Residual Stresses in a Glass Plate Cooled Symmetrically from Both Surfaces,”J. Am. Ceram. Soc.,48 (9),480–487 (1965).

Sinha, N.K., On the Studies of Rheo-Optical Response of Plate Glass in a Wide Temperature Range.PhD. Thesis, Univ. Waterloo, Waterloo, Ontario, Canada (1971).

Coker, E.G. andFilon, L.N.G., A Treatise on Photoelasticity, University Press, Cambridge, England (1931).

Kraus, C.A. andDarby, E.H., “A Study of the Conduction Process in Ordinary Soda-Lime Glass,”J. Am. Chem. Soc.,44 (12),2783–2797 (1922).

Ernsberger, F.M., Advances in Glass Technology, Plenum Press, New York, 511–524 (1962).

Acloque, P., “Comparison Between Heat Transfer Conditions and Setting up of Strain in Glass during Heat Treatment,”J. Am. Ceram. Soc.,44 (7),364–373 (1961).

Gardon, R., The Tempering of Flat Glass by Forced Convection, VII Int. Cong. Glass, Brussels, Paper 79 (1965).

Jakob, M., Heat Transfer,1,John Wiley & Sons, Inc.,New York (1949).

Carslaw, H.S. and Jaeger, J.C., Conduction of Heat in Solids, 2nd Edition, Oxford at the Claredon Press (1959).

Johns, D.J., Thermal Stress Analysis, Pergamon Press, New York (1965).

Gardon, R., “A Review of Radiant Heat Transfer in Glass,”J. Am. Ceram. Soc.,44 (7),305–312 (1961).

Hunt, J.W., Dalby, D.A. andBateson, S., A Photoelastic Stress Analyser, Technique, Muirhead and Co., Ltd., Beckenham, England,9 (1) (1965).

Garden, G.K., Characteristics of Window Glass, Nat. Res. Council of Canada, Div. Bld. Res., Canadian Bld. Dig., (60) (1964).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sinha, N.K. Stress state in tempered glass plate and determination of heat-transfer rate. Experimental Mechanics 18, 25–34 (1978). https://doi.org/10.1007/BF02326554

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02326554