Conclusions

-

1.

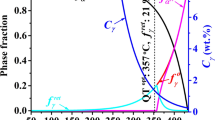

Heating the KhN56MBYuD alloy before quenching at 980–1180°C for 0.5–2 h helps dissolve the eutectic, increase the volume fraction of the sulfide (compared to the as-received state), coagulate the carbonitride, and significantly grow the grains of the γ solid solution.

-

2.

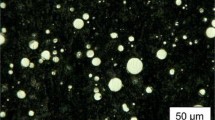

The most homogeneous structure with a low content of nonmetallic inclusions, uniform distribution of the carbonitride, and grain size of the γ solid solution of less than 600 μm were found in the KhN56MBYuD (ESM) alloy after holding at 1130°C for 2 h.

-

3.

The short-term mechanical properties of a cast, tubular billet after heat treatment under the optimum conditions are a little bit higher than the properties obtained in hot-deformed rods. This leads us to recommend the KhN56MBYuD alloy for cast massive objects which are not possible to produce by hot-deformation techniques.

Similar content being viewed by others

References

S. B. Maslenkov, High-Temperature-Strength Steels and Alloys [in Russian], Metallurgiya, Moscow (1983).

A. B. Korostelev, Yu. A. Bashnin, and A. D. Ivanov, "Kinetics of phase transformations in the KhN56MBYuD alloy produced by various techniques," Paper No. 5778 Deposited with Chermetinformatsiya (1991).

Yu. A. Bashnin, V. N. Isakina, and E. A. Maslenkova, Effect of Remelting Processes on the Structure and Properties of Steels [in Russian], Metallurgiya, Moscow (1991).

G. S. Ershov and L. A. Poznyak, Microhardness of Metals and Alloys [in Russian], Metallurgiya, Moscow (1985).

Ya. N. Malinochka and G. Z. Koval'chuk, Sulfides in Steels and Cast Irons [in Russian], Metallurgiya, Moscow (1988).

Additional information

MVMI, NIKIÉT. Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 19–22, March, 1993.

Rights and permissions

About this article

Cite this article

Bashnin, Y.A., Korostelev, A.B. Selection of quenching conditions for the KhN56MBYuD alloy of electroslag remelting. Met Sci Heat Treat 35, 150–154 (1993). https://doi.org/10.1007/BF00776840

Issue Date:

DOI: https://doi.org/10.1007/BF00776840