Abstract

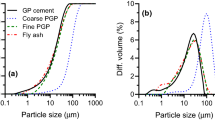

This paper evaluates feasibility of alkali activation to boost the reactivity and cementitious properties of recycled glass powder (GP), when it is used in four different binary mixtures with ordinary Portland cement (OPC), alkali activated slag or fly ash, and calcium hydroxide. It is found that the detrimental effect of alkaline solution on hydration of OPC could not be compensated by enhancement of the reactivity of GP. By optimized mixture design and preferably elevated temperature of curing, a positive performance of glass powder in alkali activated slag–GP and fly ash–GP mortars was achieved, where high volume of GP can be effectively utilized. SEM/EDS analysis confirmed that GP increases the silica content of the hydration (geopolymerization) products of slag (C–A–S–H) and fly ash (N–A–S–H). Proper design of GP–CH binders and use of high molarities of NaOH solution can results in formation of calcium–silicate–hydrate products with a composition close to tobermorite, which can provide moderate compressive strength of mortars (21 MPa at 28 days) based on CH–GP binder. Finally, GP particles were observed to not cause alkali silica reaction (ASR) expansion in alkali activated systems.

Similar content being viewed by others

References

Scrivener KL (2014) Options for the future of cement. Indian Concr J 88(7):11–21

Gartner E (2004) Industry interesting approaches to “low-CO2” cements. Cement Concr Res 34:1489–1498

Gartner E, Hirao H (2015) A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cement Concr Res 78:126–142

Damtoft JS, Lukasik J, Herfort D, Sorrentino D, Gartner EM (2008) Sustainable development and climate change initiatives. Cement Concr Res 38(2):115–127

Juenger MCG, Winnefeld F, Provis JL, Ideker JH (2011) Advances in alternative cementitious binders. Cement Concr Res 41:1232–1243

Shi C, Krivenko P, Roy D (2006) Alkali-activated cements and concrete. Taylor & Francis, Abingdon

Bernal SA, Provis JL (2014) Durability of alkali-activated materials: progress and perspectives. J Am Ceram Soc 97(4):997–1008

Brough AR, Atkinson A (2002) Sodium silicate-based, alkali-activated slag mortars: Part I. Strength, hydration and microstructure. Cement Concr Res 32(6):865–879

Shi C, Fernández Jiménez A, Palomo A (2011) New cements for the 21st century: the pursuit of an alternative to portland cement. Cement Concr Res 41(7):750–763

Ismail I, Bernal SA, Provis JL, San Nicolas R, Hamdan S, Van Deventer JSJ (2014) Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cement Concr Compos 45:125–135

Richardson IG, Brough AR, Groves GW, Dobson CM (1994) The characterization of hardened alkali-activated blast-furnace slag pastes and the nature of the calcium silicate hydrate (C-S-H) phase. Cement Concr Res 24(5):813–829

Haha MB, Le Saout G, Winnefeld F, Lothenbach B (2011) Influence of activator type on hydration kinetics, hydrate assemblage and microstructural development of alkali activated blast-furnace slags. Cement Concr Res 41:301–310

Cartwright C, Rajabipour F, Radlińska A (2015) Shrinkage characteristics of alkali activated slag cements. J Mater Civil Eng 27(7):B4014007

Fernández-Jiménez A, Puertas F, Polamo JG (1999) Alkali activated slag mortars: mechanical strength behavior. Cement Concr Res 29:1313–1321

Douglas E, Bilodeau A, Malhotra VM (1992) Properties and durability of alkali-activated slag concrete. ACI Mater J 89:509–516

Shayan A, Xu A (2004) Value-added utilisation of waste glass in concrete. Cement Concr Res 34(1):81–89

Idir R, Cyr M, Tagnit-Hamou (2011) Pozzolanic properties of fine and coarse color-mixed glass cullet. Cement Concr Comp 33(1):19–29

Rajabipour F, Maraghechi H, Shafaatian SMH (2012) ASR and its mitigation in mortars containing recycled Soda–Lime glass aggregates. In: 14th international conference on concrete alkali aggregate reactions (ICAAR), Austin

Maraghechi H, Shafaatian SMH, Fischer G, Rajabipour F (2012) The role of residual cracks on alkali silica reactivity of recycled glass aggregates. Cement Concr Compos 34:41–47

Rajabipour F, Maraghechi H, Fischer G (2010) Investigating the alkali silica reaction of recycled glass aggregates in concrete materials. J Mater Civil Eng 22(12):1201–1210

Maraghechi H, Maraghechi M, Rajabipour F, Pantano CG (2014) Pozzolanic reactivity of recycled glass powder at elevated temperatures: reaction stoichiometry, reaction products, and effect of alkali activation. Cement Concr Compos 53:105–114

Afshinnia K, Rangaraju PR (2015) Influence of fineness of ground recycled glass on mitigation of alkali–silica reaction in mortars. Constr Build Mater 81:257–267

Federico LM, Chidiac SE (2009) Waste glass as a supplementary cementitious material in concrete—critical review of treatment methods. Cement Concr Compos 31(8):606–610

Dyer T, Dhir R (2001) Chemical reactions of glass cullet used as cement component. J Mater Civil Eng 13(6):412–417

Shi C, Zheng K (2007) A review on the use of waste glasses in the production of cement and concrete. Resour Conserv Recycl 52(2):234–247

Shao Y, Lefort T, Moras S, Rodriguez D (2000) Studies on concrete containing ground waste glass. Cement Concr Res 30(1):91–100

Shayan A, Xu A (2006) Performance of glass powder as a pozzolanic material in concrete: a field trial on concrete slabs. Cement Concr Res 36:457–468

Remarque W, Urbonas L, Heinz D (2003) About the behaviour of glass powder in pastes and mortars with cement. In: Proceedings of the 11th international congress on the chemistry of cement (ICCC), South Africa, pp 2117–2127

Mirzahosseini M, Riding KA (2014) Effect of curing temperature and glass type on the pozzolanic reactivity of glass powder. Cement Concr Res 58:103–111

Snellings R (2013) Solution-controlled dissolution of supplementary cementitious material glasses at pH 13: the effect of solution composition on glass dissolution rates. J Am Ceram Soc 96(8):2467–2475

Paul A (1990) Chemistry of glasses, 2nd edn. Chapman and Hall, New York

Bunker BC (1994) Molecular mechanism for corrosion of silica and silicate glasses. J Non Cryst Solids 179:300–308

Grambow B (1002) Geochemical approach to glass dissolution. In: Clark DE, Zoitos BK (eds) Corrosion of glass, ceramics, and ceramic superconductors: principles, testing, characterization, and applications. Noyes Publication, Saddle River

Maraghechi H, Rajabipour F, Pantano CG, Burgos W (2016) Effect of calcium on dissolution and precipitation reactions of amorphous silica at high alkalinity. Cement Concr Res 87:1–13

Rajabipour F, Giannini E, Dunant C, Ideker JH, Thomas MDA (2015) Alkali-silica reaction: current understanding of the reaction mechanisms and the knowledge gaps. Cement Concr Res 76:130–146

Smaoui N, Berube MA, Fournier B, Bissonnette B, Durand B (2005) Effects of alkali addition on the mechanical properties and durability of concrete. Cement Concr Res 35:203–212

Shayan A, Ivanusec I (1989) Influence of NaOH on mechanical properties of cement paste and mortar with and without reactive aggregate. In: 8th international conference on alkali—aggregate reaction, The Society of Materials Science, Kyoto, pp 715–720

Gassó BM (2015) Impact of alkali salts on the kinetics and microstructural development of cementitious systems. Dissertation, École Polytechnique Fédérale de Lausanne

Oka Y, Tomozawa M (1980) Effect of alkaline earth ion as an inhibitor to alkaline attack on silica glass. J Non Cryst Solids 42(1–3):535–543

Utton CA, Hand RJ, Hyatt NC, Swanton SW, Williams SJ (2013) Formation of alteration products during dissolution of vitrified ILW in a high-pH calcium-rich solution. J Nucl Mater 442(1):33–45

Fournier M, Gin S, Frugier P (2014) Resumption of nuclear glass alteration: state of the art. J Nucl Mater 448:348–363

Mercado-Depierre S, Angeli F, Frizon F, Gin S (2013) Antagonist effects of calcium on borosilicate glass alteration. J Nucl Mater 441(1):402–410

Acknowledgments

The authors gratefully acknowledge support received from the National Science Foundation (NSF) under Grant# CMMI 1030708 awarded to the third author. Any opinions, findings and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation. The authors are also thankful to the research staff at Penn State’s Materials Characterization Laboratory (MCL) for their valuable suggestions and assistance. Special thanks to Mr. William Shaker at Potters Industries LLC for supplying glass powders.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maraghechi, H., Salwocki, S. & Rajabipour, F. Utilisation of alkali activated glass powder in binary mixtures with Portland cement, slag, fly ash and hydrated lime. Mater Struct 50, 16 (2017). https://doi.org/10.1617/s11527-016-0922-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-016-0922-5